Bread rich in litchi bonded phenol and preparation method thereof

A technology combining phenol and lychee, which is applied in the processing of dough, the function of food ingredients, food processing, etc., can solve the problems of rough taste of whole grain bread and low content of combined phenol.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

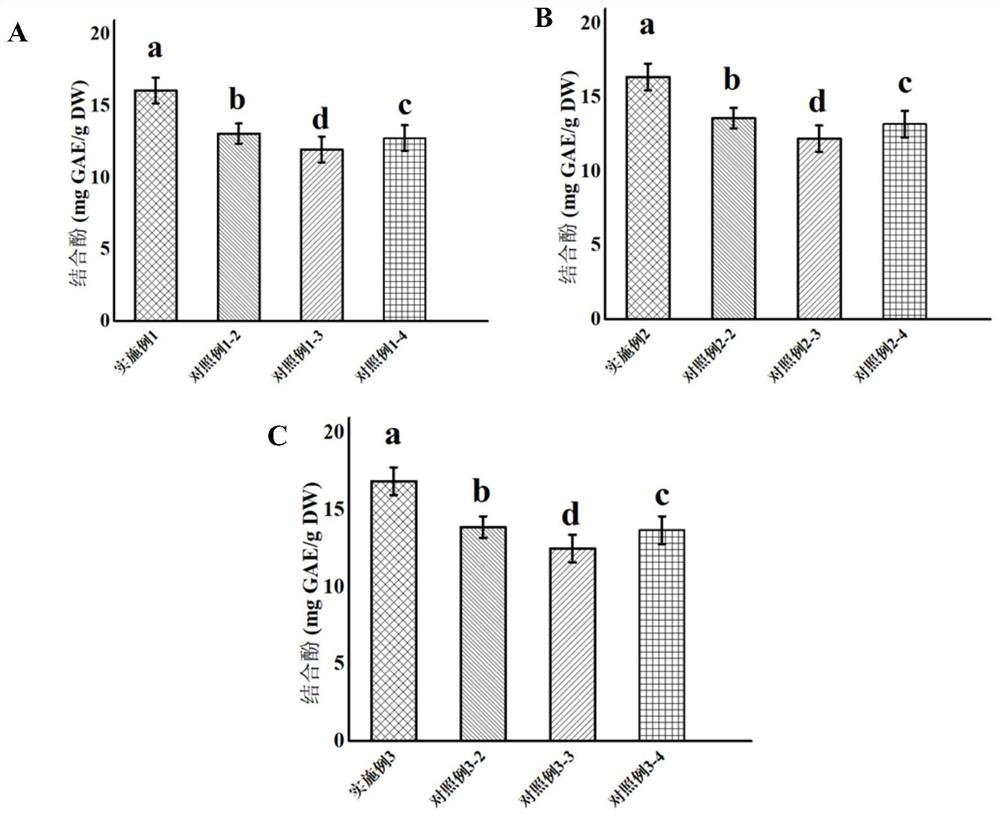

Embodiment 1

[0056] The bread of Example 1 includes the following raw materials in parts by mass: 11 parts of lychee combined with phenol fruit powder with a particle size of 10 μm, 1 part of dry yeast, 3 parts of sucrose, 2 parts of salt, 50 parts of egg liquid, 73 parts of high-gluten flour, 250 parts of water.

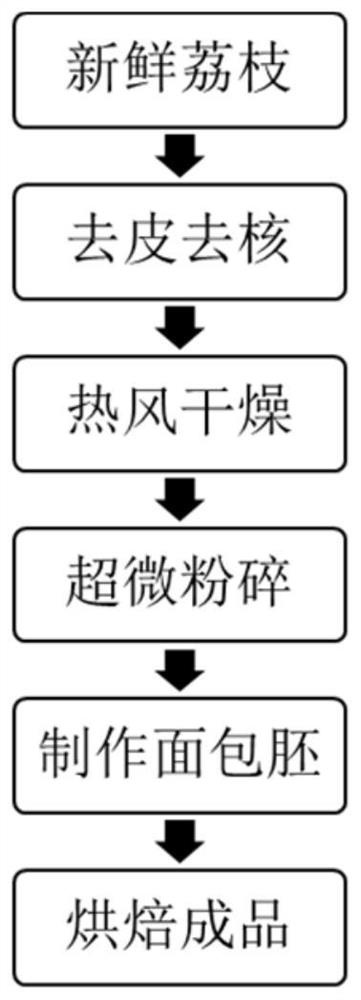

[0057] Its preparation method comprises the following steps ( figure 1 ):

[0058] S1. Prepare fresh lychee pulp: select fresh lychees, wash them, peel and remove the core, wash the remaining lychee pulp, put it into a juicer to squeeze the juice, and centrifuge to remove the clear liquid to obtain fresh lychee pulp;

[0059] S2. Intermittent process - combined heat pump infrared drying and ultrafine grinding: ① Fresh lychee pomace is first dried by heat pump for 1 hour, combined with heat pump and infrared drying for 4 hours, and shut down for 2 hours; ② Then infrared dried for 1 hour, heat pump combined with infrared drying for 4 hours, shut down intermittently 2h, this step...

Embodiment 2

[0075] The bread of Example 2 includes the following raw materials in parts by mass: 11 parts of lychee combined with phenol fruit powder with a particle size of 255 μm, 1 part of dry yeast, 3 parts of sucrose, 2 parts of salt, 50 parts of egg liquid, 73 parts of high-gluten flour, 250 parts of water.

[0076] Its preparation method comprises the following steps:

[0077] S1. Prepare fresh lychee pulp: select fresh lychees, wash them, peel and remove the core, wash the remaining lychee pulp and put it into a juicer to squeeze it into litchi pulp;

[0078] S2. Intermittent process - combined heat pump infrared drying and ultrafine grinding: ① Fresh lychee pomace is first dried by heat pump for 1 hour, combined with heat pump and infrared drying for 4 hours, and shut down for 2 hours; ② Then infrared dried for 1 hour, heat pump combined with infrared drying for 4 hours, shut down intermittently 2h, this step ② cycle 4 times (total drying 25h, excluding downtime); Among them, th...

Embodiment 3

[0094] The bread of Example 3 includes the following raw materials in parts by mass: 11 parts of lychee combined with phenol fruit powder with a particle size of 500 μm, 1 part of dry yeast, 3 parts of sucrose, 2 parts of salt, 50 parts of egg liquid, 73 parts of high-gluten flour, 250 parts of water.

[0095] Its preparation method comprises the following steps:

[0096] S1. Prepare fresh lychee pulp: select fresh lychees, wash them, peel and remove the core, wash the remaining lychee pulp and put it into a juicer to squeeze it into litchi pulp;

[0097] S2. Intermittent process - combined heat pump infrared drying and ultrafine grinding: ① Fresh lychee pomace is first dried by heat pump for 1 hour, combined with heat pump and infrared drying for 4 hours, and shut down for 2 hours; ② Then infrared dried for 1 hour, heat pump combined with infrared drying for 4 hours, shut down intermittently 2h, this step ② cycle 4 times (total drying 25h, excluding downtime); Among them, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com