A kind of hydrophilic sulindac molecularly imprinted magnetic nano resin ball and its preparation method and application

A magnetic nanosphere, molecular imprinting technology, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., to achieve the effects of strong reusability, strong magnetic response, and high binding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of hydrophilic sulindac molecularly imprinted magnetic nano-resin balls, comprising the following steps:

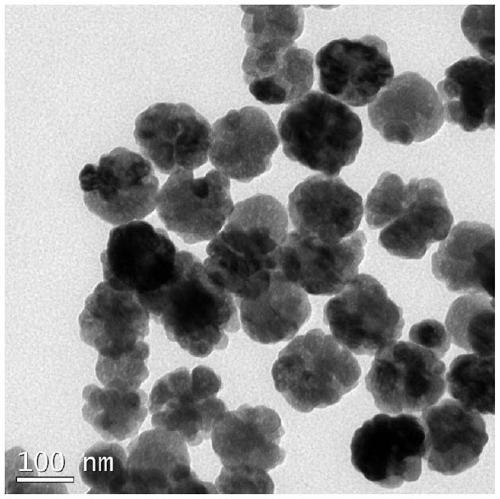

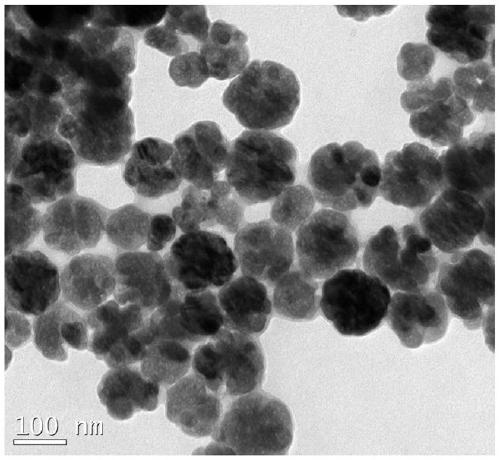

[0035] Step 1. Put 0.30g of ferric chloride, 1.00g of sodium acetate, 0.02g of sodium polyacrylate, 6.6mL of ethylene glycol and 10mL of diethylene glycol in a reactor, and react at 180°C for 7 hours. After the reaction, The reaction product was washed with ultrapure water until neutral. Then, the obtained product was vacuum-dried at 30° C. and 0.05 MPa for 3 hours to obtain carboxyl magnetic nanospheres. Such as figure 1 As shown, the particle size of the prepared carboxyl magnetic nanospheres is about 110-120 nm.

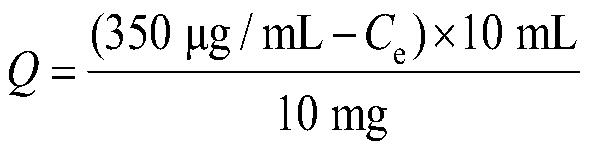

[0036] Step 2: Put 100mg of carboxyl magnetic nanospheres, 10mg of sulindac, 5mL of ultrapure water and 1.8mL of ammonia water in a reaction vessel, stir and react at room temperature for 10min, then add 0.01g of resorcinol and stir for 0.5h, and finally add 0.01 mL formaldehyde, polymerized at room temperature for 3 hours, and ...

Embodiment 2

[0048] A preparation method of hydrophilic sulindac molecularly imprinted magnetic nano-resin balls, comprising the following steps:

[0049] Step 1. Put 0.45g of ferric chloride, 1.5g of sodium acetate, 0.03g of sodium polyacrylate, 6.8mL of ethylene glycol and 12mL of diethylene glycol in a reactor, and react at 190°C for 10 hours. After the reaction, The reaction product was washed with ultrapure water until neutral. Then, vacuum-dry the obtained product at 45° C. and 0.05 MPa for 4.5 hours to obtain carboxyl magnetic nanospheres.

[0050] Step 2: Put 110mg of carboxyl magnetic nanospheres, 12mg of sulindac, 6mL of ultrapure water and 1.85mL of ammonia water in a reaction vessel, stir and react at room temperature for 20min, then add 0.04g of resorcinol and stir for 0.8h, and finally add 0.02 mL formaldehyde, polymerized at room temperature for 4 hours, and cured at 20°C for 8 hours.

[0051] Step 3, after the polymerization reaction is completed, the solid polymer genera...

Embodiment 3

[0062] A preparation method of hydrophilic sulindac molecularly imprinted magnetic nano-resin balls, comprising the following steps:

[0063] Step 1. Put 0.504g of ferric chloride, 2.0g of sodium acetate, 0.05g of sodium polyacrylate, 7mL of ethylene glycol and 13mL of diethylene glycol in a reactor, and react at 200°C for 11 hours. After the reaction, put The reaction product was washed with ultrapure water until neutral. Then, vacuum-dry the obtained product at 50° C. and 0.05 MPa for 5.5 hours to obtain carboxyl magnetic nanospheres.

[0064] Step 2: Put 250mg of carboxyl magnetic nanospheres, 20mg of sulindac, 10mL of ultrapure water and 2mL of ammonia water in a reaction vessel, stir and react at room temperature for 30min, then add 0.1g of resorcinol and stir for 1.2h, and finally add 0.05mL Formaldehyde, polymerized at room temperature for 6h, and cured at 25°C for 10h.

[0065] Step 3, after the polymerization reaction is completed, the solid polymer generated in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com