Smoke moisture and waste heat recovery device based on hollow micro-nano porous ceramic membranes

The technology of a waste heat recovery device and a porous ceramic membrane is applied in the field of the waste heat recovery device of flue gas moisture, which can solve the problems of high cost, harsh working environment, easy corrosion of equipment materials, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

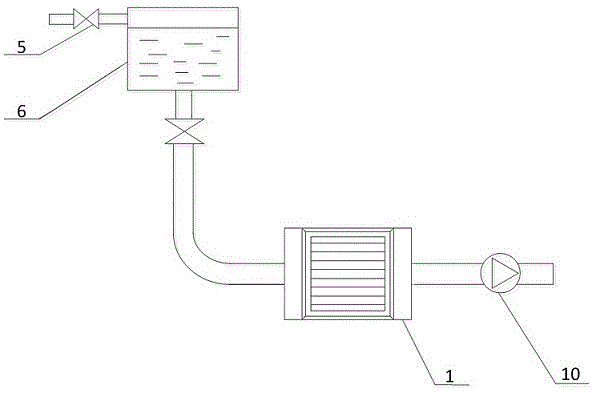

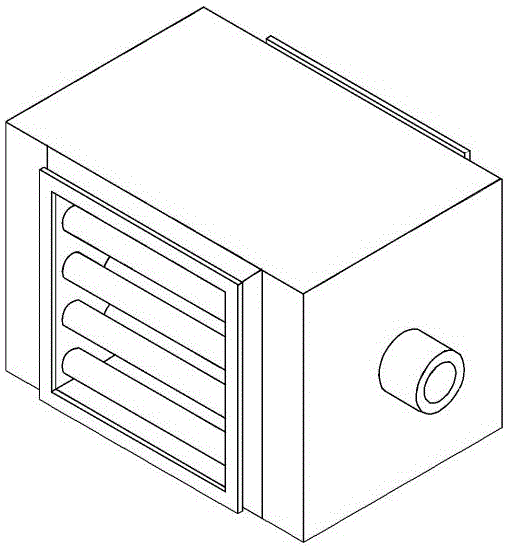

[0016] The present invention provides a flue gas moisture waste heat recovery device based on a hollow micro-nano porous ceramic membrane. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

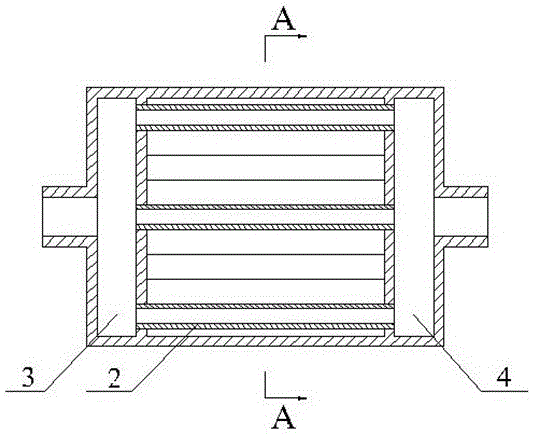

[0017] The hollow micro-nano porous ceramic membrane module (1) is composed of several hollow micro-nano porous ceramic membranes with certain structural parameters and performance parameters, that is, membrane tubes (2). Arranged in staggered columns. The two ends of the hollow micro-nano porous ceramic membrane module (1) are provided with a water inlet chamber (3) and a water outlet chamber (4), the water inlet chamber is connected with a valve (5) and a water supply tank (6), and the water outlet chamber is connected with a water pump (10). The water supply tank (6) is provided with a water tank water inlet (7), a water tank air hole (9) and a water tank water outlet (8).

[0018] First check the water level o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com