Preparation method for electrode MnO2@Ni-Al LDH composite material of super capacitor

A technology of supercapacitors and composite materials, used in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of poor stability of modified electrodes, and achieve improved electrochemical performance, uniform size, and short modification time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

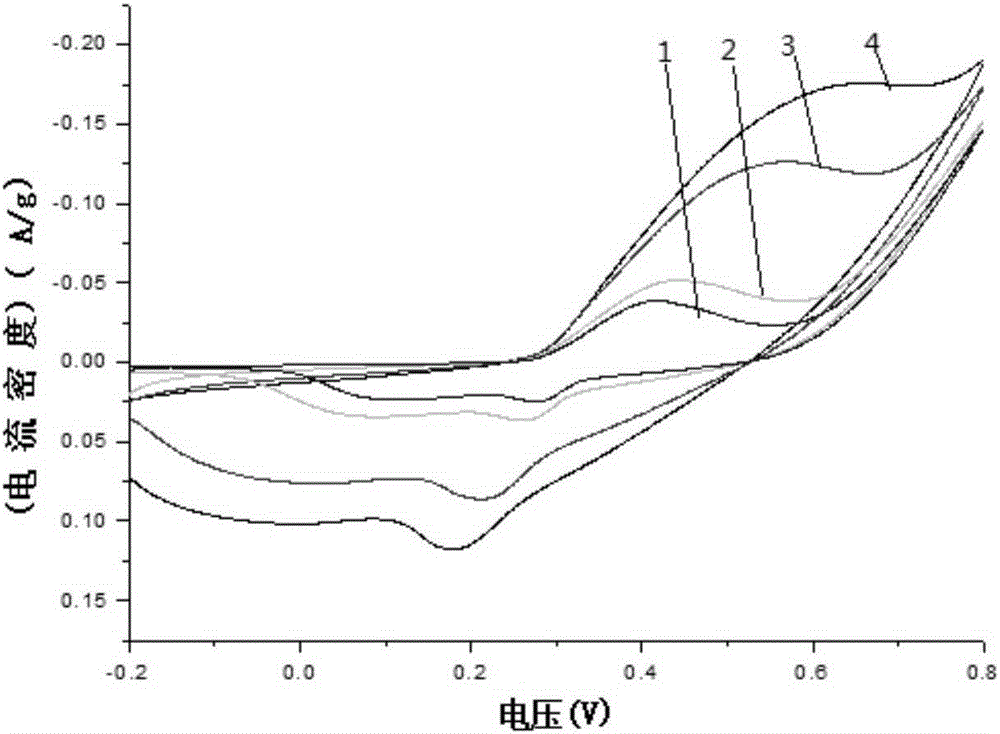

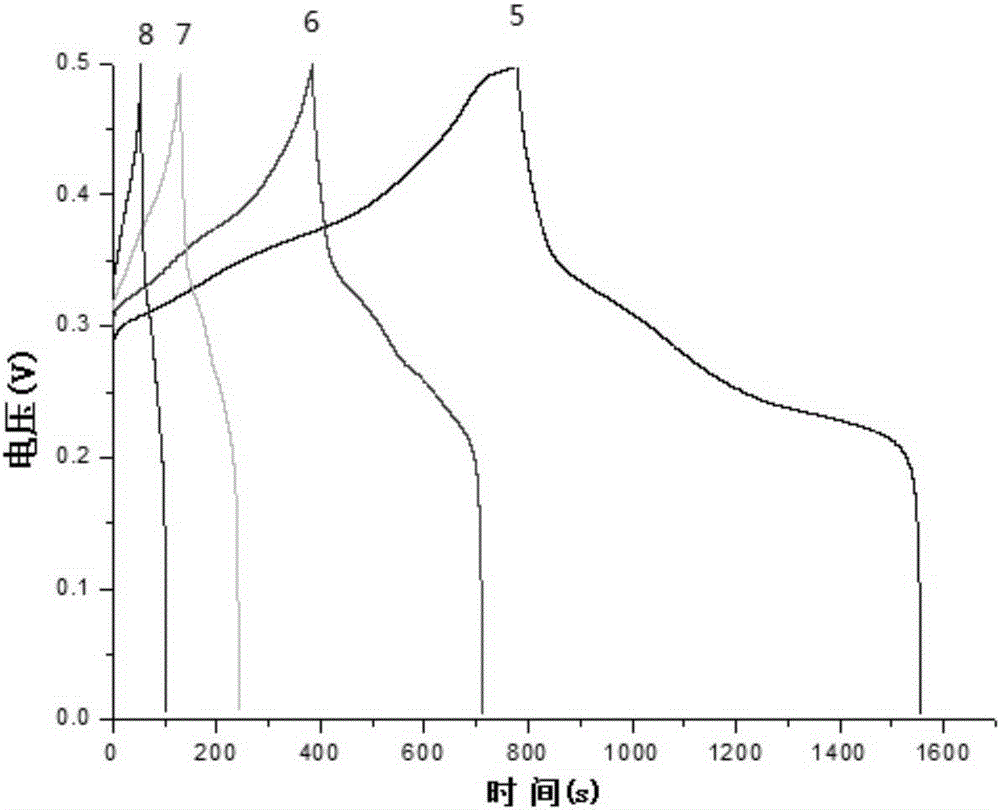

Embodiment 1

[0035] (1) Foam nickel pretreatment: Ultrasound with 3M HCl for 10 minutes, wash with deionized water and absolute ethanol for 15 minutes each;

[0036] (2) 60 DEG C of vacuum-drying with pretreated foamed nickel, the quality that weighs is 0.04694g;

[0037] (3) Weigh NiCl 2 ·6H 2 O is 0.7271g, AlCl 3 0.1433g, KNO 3 Dissolve 1.5341g in 100mL deionized water at room temperature, and use an electrochemical workstation CHI660C three-electrode system for electrodeposition (foam nickel as the working electrode, Hg / HgO as the reference electrode, and Pt electrode as the counter electrode), select -0.9V Carry out constant potential deposition, the deposition time is 1200s;

[0038] (4) After deposition, the nickel foam was rinsed with deionized water, dried under vacuum at 60° C., and weighed 0.04827 g.

Embodiment 2

[0040] (1) Foam nickel pretreatment: Ultrasound with 3M HCl for 10 minutes, wash with deionized water and absolute ethanol for 15 minutes each;

[0041] (2) 60 ℃ of vacuum-drying with pretreated foamed nickel, the quality that weighs is 0.05341g;

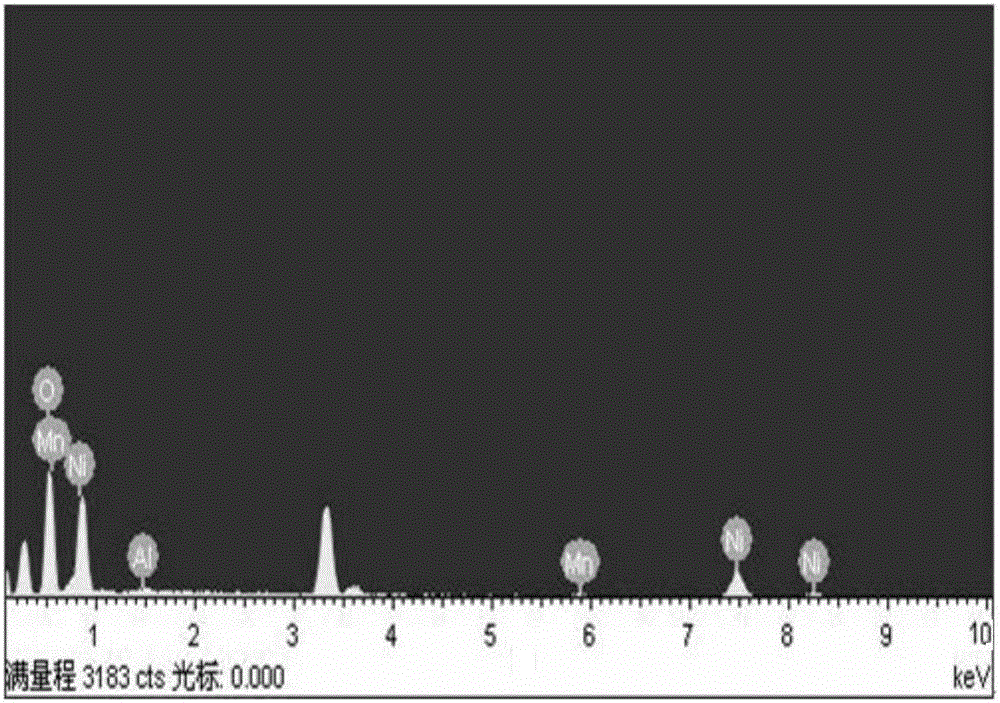

[0042] (3) Weigh NiCl 2·6H 2 O is 0.7216g, AlCl 3 0.1401g, KNO 3 1.5334g, KMnO 4 Dissolve 0.1601g in 100mL deionized water at room temperature, and use an electrochemical workstation CHI660C three-electrode system for electrodeposition (foam nickel as the working electrode, Hg / HgO as the reference electrode, and Pt electrode as the counter electrode), select -0.9V Carry out constant potential deposition, the deposition time is 1200s;

[0043] (4) After deposition, the nickel foam was rinsed with deionized water, dried under vacuum at 60° C., and weighed 0.05459 g.

Embodiment 3

[0045] (1) Foam nickel pretreatment: Ultrasound with 3M HCl for 10 minutes, wash with deionized water and absolute ethanol for 15 minutes each;

[0046] (2) 60 ℃ of vacuum-drying with pretreated foamed nickel, the quality that weighs is 0.06556g;

[0047] (3) Weigh NiCl 2 ·6H 2 O is 0.7369g, AlCl 3 0.1370g, NaNO 3 1.5435g, KMnO 4 Dissolve 0.3282g in 100mL deionized water at room temperature, and conduct electrodeposition with an electrochemical workstation CHI660C three-electrode system (foamed nickel as the working electrode, Hg / HgO as the reference electrode, and Pt electrode as the counter electrode), and select -1V for Constant potential deposition, the deposition time is 400s;

[0048] (4) After deposition, the nickel foam was rinsed with deionized water, dried under vacuum at 60° C., and weighed 0.06682 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com