Device and method for monitoring flux quality changes on line

A quality change and flux technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of reduced sintering output, low BTP temperature, increased production cost of sintering process, etc., to improve sintering yield, material layer temperature uniformity, Eliminate the effect of high return rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

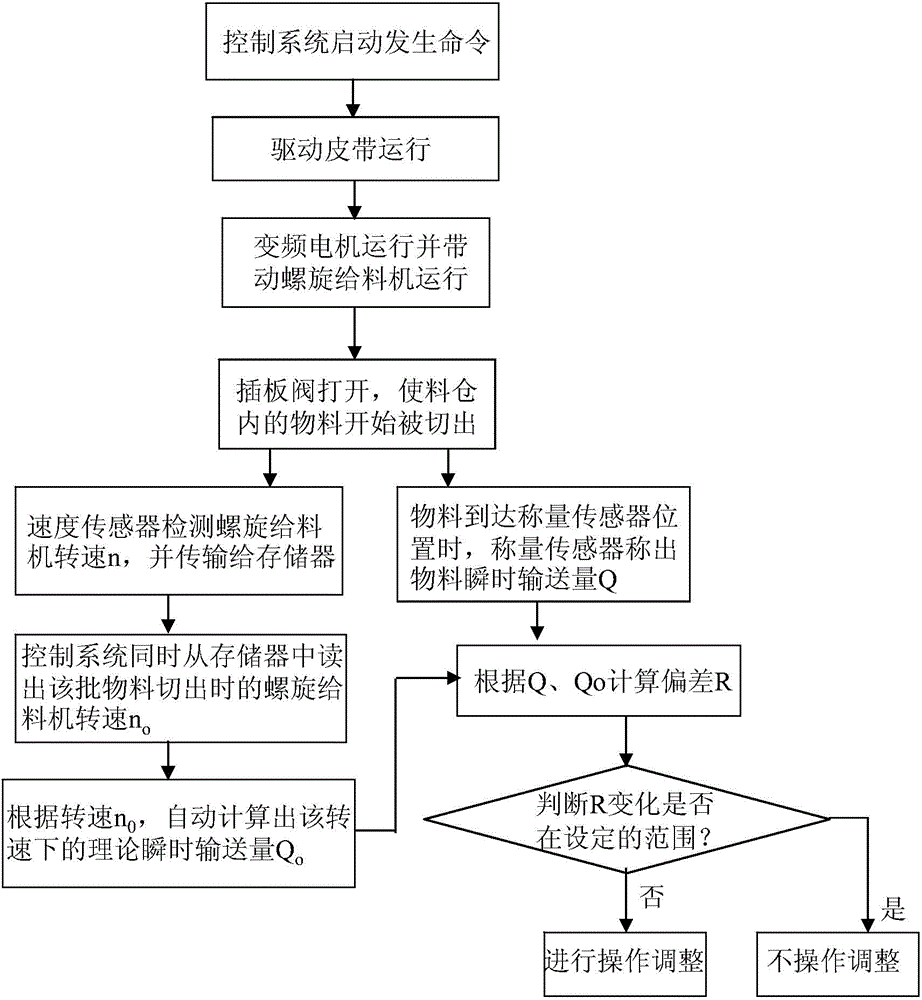

[0048] Material filling coefficient φ: 0.33, screw feeder inclination coefficient β: 1, material bulk density r: 0.9t / m 3 , the speed of the screw feeder n: 90r / min, the screw pitch S: 0.25m; the screw diameter D: 0.25m, the theoretical instantaneous delivery volume Q is calculated according to formula 1 0 : 25t / h, the actual instantaneous delivery volume Q of this batch of materials: 19t / h, the degree of deviation R=19 / 25100%=76%.

[0049] When R < 80% alarm occurs frequently in the deviation degree R, the process will not be adjusted, but pay close attention to whether the discharge volume is normal, whether the equipment has deviation, jamming, etc., and notify the inspection personnel to go to the site to check and deal with the equipment. problem, make sure the load rate is normal.

example 2

[0051] As described in Example 1, when the degree of deviation R is 80% to 100%, it is a normal state and no adjustment is required.

example 3

[0053] As described in Example 1, when the degree of deviation R is 100% to 120%, and there are frequent alarms that exceed 120% instantaneously, most of the quicklime at this time has a phenomenon of coarser particle size and darker color, and it is necessary to reduce the water ratio of the mixer in time 0.1-0.2%, if necessary, increase the coke powder by 0.5%, and closely follow the change of CaO content in sintered ore.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com