Method for degrading organic pollutant in water through activated persulfate

A technology for activating persulfate and organic pollutants, used in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve problems such as secondary pollution, achieve cost reduction, rapid mass transfer, and reduced Effects of drug consumption and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

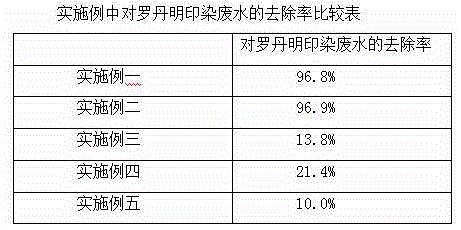

[0019] A method of activating persulfate degradation water organic pollutants of the present invention is applied to the treatment of printing and dyeing wastewater containing 10mg / L rhodamine, and its concrete steps are as follows:

[0020] (1). Prepare 100mL60g / L sodium hydroxide solution, which is recorded as solution A;

[0021] (2). Prepare 100 mL of a mixed solution of magnesium nitrate and aluminum nitrate with a molar ratio of 3:1, and record it as solution B;

[0022] (3). Stir vigorously to mix the solution B, and add the solution A solution to the solution B, and continue to stir for 90 minutes to obtain a composite solution;

[0023] (4). Heat the above composite solution, keep the temperature at 65°C, let it stand for 20 hours, take it out after natural cooling, and obtain emulsion C;

[0024] (5). Put the emulsion C into the printing and dyeing wastewater to be treated. The volume ratio of the printing and dyeing wastewater to be treated and the emulsion is 10:1...

Embodiment 2

[0026] The present embodiment is basically the same as Example one, and the difference is that the potassium persulfate solid is added as described in the above step (5), the mass concentration of potassium persulfate after stirring and dissolving is 100mg / L, and the water sample is taken after the reaction for determination , among which, the removal rate of rhodamine in printing and dyeing wastewater is 96.9%.

Embodiment 3

[0028] This example is basically the same as Example 1, the difference is that the step of adding potassium persulfate in the operation step (5) in Example 1 is omitted, and the water sample is taken after the reaction for measurement. The clear removal rate is 13.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com