Green and environmental-friendly thermal-insulation dry powder mortar

A dry powder mortar, green and environmental protection technology, applied in the field of construction mortar, can solve the problems of roof water leakage, occupying space, and sanding of walls, and achieves good thermal insulation performance, good fire resistance performance, and good workability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

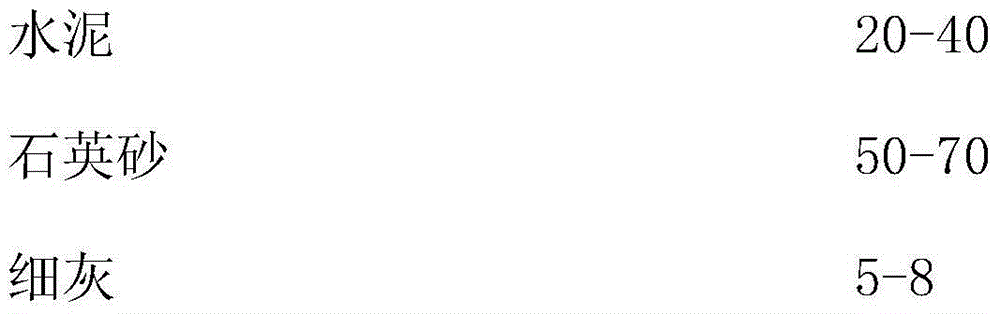

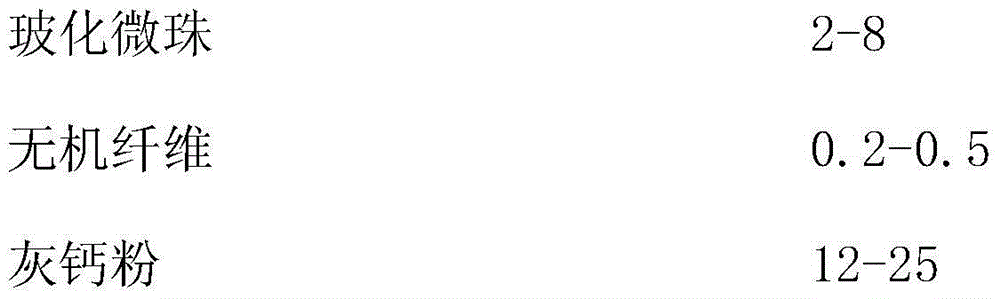

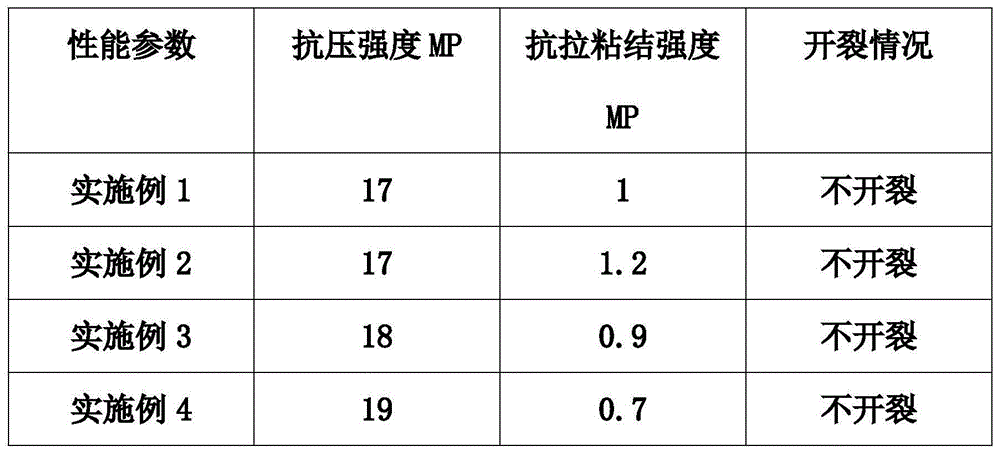

[0015] Embodiments 1-4: Weigh each raw material according to the given mass parts in Table 1, and then mix and stir them for 2-4 minutes to obtain thermal insulation dry powder mortar.

[0016] Wherein the strength of the cement used in Example 1 is not less than 52.5, the thickness of the quartz sand is below 100 mesh, and the fine ash is the fine ash after straw burning, and the density of the vitrified microbeads is 100kg / m 3 , the inorganic fiber is one of glass fiber, quartz glass fiber, boron fiber or ceramic fiber, and the monofilament length of the inorganic fiber is 10mm±2mm.

Embodiment 2

[0017] The strength of the cement used in Example 2 is not less than 52.5, the thickness of the quartz sand is below 100 mesh, and the fine ash is the fine ash after straw burning, and the density of the vitrified microbeads is 100kg / m 3 , the inorganic fiber is one of glass fiber, quartz glass fiber, boron fiber or ceramic fiber, and the monofilament length of the inorganic fiber is 10mm±2mm.

Embodiment 3

[0018] The strength of the cement used in Example 3 is not less than 52.5, the thickness of the quartz sand is below 100 mesh, and the fine ash is the fine ash after straw burning, and the density of the vitrified microbeads is 100kg / m 3 , the inorganic fiber is one of glass fiber, quartz glass fiber, boron fiber or ceramic fiber, and the monofilament length of the inorganic fiber is 10mm±2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com