Process for producing propylene oxide

A technology of propylene oxide and cumene hydroperoxide, which is applied in the direction of organic chemistry, can solve the problem of high energy consumption, achieve the effects of improving purity, good technical effect, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

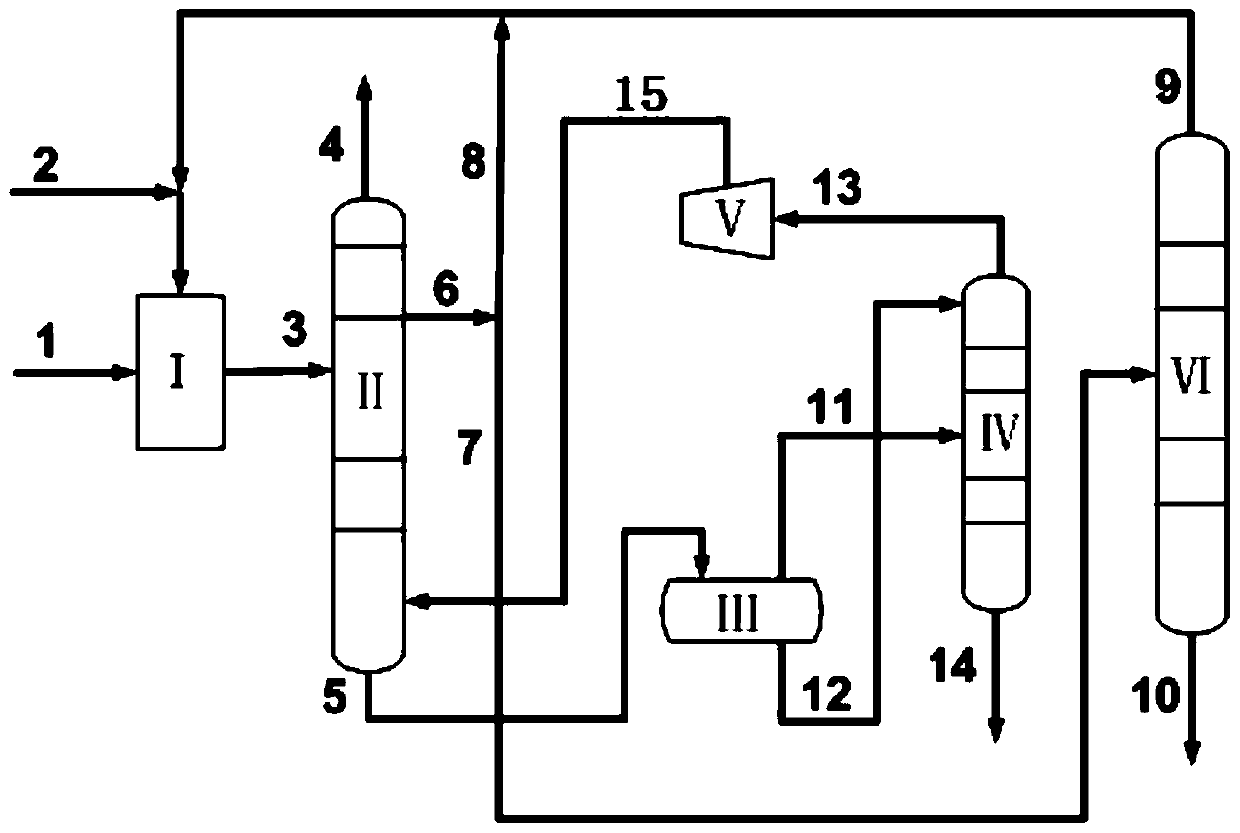

[0032] like figure 1As shown, taking a 100,000-ton / year PO plant as an example, the raw material cumene hydroperoxide 1 and fresh propylene 2 react in reactor I to form a liquid phase stream 3 containing propylene oxide and propylene. Stream 3 is sent to the middle part of the high-pressure propylene recovery tower II. After separation, the propylene 6 obtained from the side line of the tower is divided into two parts, most of the propylene 8 is sent back to the epoxidation reaction system I to participate in the reaction, and a small part of propylene 7 enters the depropanizer VI for refining , the heavy component 5 obtained in the bottom of the tower is sent to the adiabatic flash tank III for separation, and the light component 4 obtained in the top of the tower is discharged. The gas phase product 11 obtained from the top of the flash tank III is sent to the middle part of the low-pressure propylene recovery tower IV, and the liquid phase product 12 obtained at the bottom ...

Embodiment 2

[0043] With [embodiment 1], just raw material and operating condition change.

[0044] In stream 3, by weight percent, the content of α,α-dimethylbenzyl alcohol is 26%, the content of cumene is 21.5%, the content of propylene oxide is 10.5%, the content of propylene is 39%, propane The content is 2%.

[0045] The operating conditions of the high-pressure propylene recovery tower are as follows: the operating pressure is 1.8MPa in gauge pressure, the operating temperature at the top of the tower is 45°C, the operating temperature at the bottom of the tower is 124°C, and the number of theoretical plates is 25.

[0046] The operating conditions of the low-pressure propylene recovery tower are as follows: the operating pressure is 0.2MPa in gauge pressure, the operating temperature at the top of the tower is 30°C, the operating temperature at the bottom of the tower is 119°C, and the number of theoretical plates is 20.

[0047] The operating conditions of the depropanizer are as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com