Reaction type non-asphalt base waterproof composition

A non-asphalt-based, composite technology, applied in carboxyl-based rubber coatings, coatings, other chemical processes, etc., can solve the problems of low production efficiency, increased production costs, unstable performance of asphalt waterproof materials, etc. Waterproof, durable and reliable, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

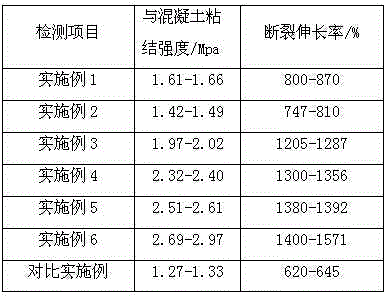

Examples

Embodiment 1

[0022] Mix 35 parts of carboxylated nitrile rubber (parts by weight, the same below), 22 parts of hydrogenated rosin glyceride and 8 parts of dibutyl fumarate, grind to paste with a colloid mill, add 0.2 parts of mercaptopropyltrimethoxysilane , continue heating and stirring to mix the materials evenly, and obtain a reactive non-bitumen-based waterproof composition, which can be directly used as a waterproof sealant.

Embodiment 2

[0024] Mix 20 parts of butyl rubber (parts by weight, the same below), 20 parts of hydrogenated rosin pentaerythritol ester and 10 parts of dioctyl fumarate, grind to a paste with a colloid mill, add 0.5 parts of 2-cyanoethyltrimethoxy Silane, 0.5 parts of propyl diallyl methyl ammonium chloride siloxane, continue heating and stirring to mix the materials evenly to obtain a reactive non-bitumen-based waterproof composition, which is coated on polyester non-woven fabrics to make waterproof Coil.

Embodiment 3

[0026] Mix 46 parts of isoprene rubber (parts by weight, the same below), 31 parts of glycerin rosin (softening point: 85-90°C) and 12 parts of dioctyl fumarate, grind to a paste with a colloid mill, add 1 part of acrylic acid dimethyl methacrylate-based aminosiloxane chloride, continue heating and stirring to mix the materials evenly, and obtain a reactive non-bitumen-based waterproof composition, which is coated on a polymer film to make a waterproof membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com