Water-based acrylic resin paint and preparing method thereof

A water-based acrylic and acrylic resin technology, applied in the field of coatings, can solve the problems of impact resistance, abrasion resistance and scratch resistance, etc., and achieve the effect of reducing the number of hydroxyl groups, good elasticity, and improving scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

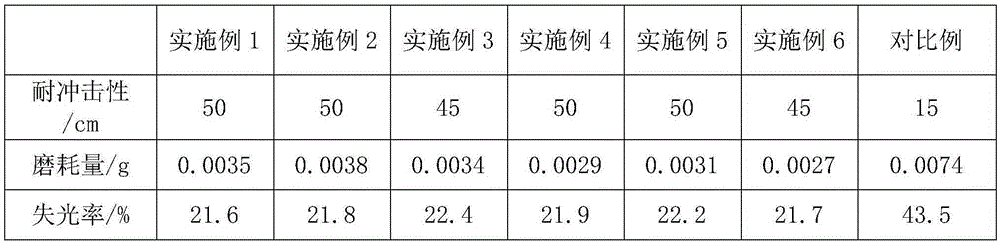

Examples

Embodiment 1

[0027] Water-based acrylic resin paint, by weight, is made of the following components: 35 parts of water-based epoxy modified acrylic resin, 12 parts of glass microspheres, 2 parts of siloxane coupling agent, 4 parts of rutile nano titanium dioxide, poly 0.5 parts of carboxylate, 24 parts of deionized water, 0.3 parts of organic chelate anti-flash rust agent, 1.2 parts of polyamide wax, 7 parts of water-based polyurethane, 9.5 parts of PCDL, 15 parts of porous powder quartz.

[0028] The steps of its preparation method are as follows:

[0029] (1) Carry out roll crushing of porous powder quartz and pass through a 60-mesh sieve, and then add it to a stirring ball mill for ball milling for 60 minutes to obtain porous powder quartz powder with a fineness of 800 mesh for use. The ratio of medium to material during ball milling is 2:1, and the pulp concentration is 65%, and the ball milling medium is glass balls;

[0030] (2) Add YDH550 into the aqueous acetic acid solution, hydr...

Embodiment 2

[0033] Water-based acrylic resin paint, by weight, is made of the following components: 40 parts of water-based epoxy modified acrylic resin, 10 parts of glass microspheres, 3.5 parts of siloxane coupling agent, 2.5 parts of rutile nano-titanium dioxide, poly 0.3 parts of carboxylate, 22 parts of deionized water, 0.5 parts of organic chelate anti-flash rust agent, 1.5 parts of polyamide wax, 9 parts of water-based polyurethane, 8 parts of PCDL, and 13 parts of porous powder quartz.

[0034] The steps of its preparation method are as follows:

[0035] (1) Carry out roll crushing of porous powder quartz and pass through a 60-mesh sieve, and then add it to a stirring ball mill for ball milling for 60 minutes to obtain porous powder quartz powder with a fineness of 800 mesh for use. The ratio of medium to material during ball milling is 2:1, and the pulp concentration is 65%, and the ball milling medium is glass balls;

[0036] (2) Add YDH550 into the aqueous acetic acid solution...

Embodiment 3

[0039] Water-based acrylic resin paint, by weight, is made of the following components: 36 parts of water-based epoxy modified acrylic resin, 14 parts of ceramic microbeads, 4 parts of siloxane coupling agent, 1 part of rutile nano-titanium dioxide, poly 0.7 parts of carboxylate, 23 parts of deionized water, 0.7 parts of organic chelate anti-flash rust agent, 1 part of polyamide wax, 10 parts of water-based polyurethane, 8.5 parts of PCDL, 11 parts of porous powder quartz.

[0040] The steps of its preparation method are as follows:

[0041] (1) Carry out roll crushing of porous powder quartz and pass through a 60-mesh sieve, and then add it to a stirring ball mill for ball milling for 60 minutes to obtain porous powder quartz powder with a fineness of 800 mesh for use. The ratio of medium to material during ball milling is 2:1, and the pulp concentration is 65%, and the ball milling medium is glass balls;

[0042] (2) Add YDH550 into the aqueous acetic acid solution, hydrolyze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com