Urea-formaldehyde resin type pentacyclic undecane microcapsule and preparation method thereof

A technology of urea-formaldehyde resin and microcapsules, which is applied in the field of microcapsules of urea-formaldehyde resin-type pentacycloundecane and its preparation, can solve problems such as bad smell and easy sublimation of pentacycloundecane, and achieve extended use and storage life, Overcoming the effects of easy sublimation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

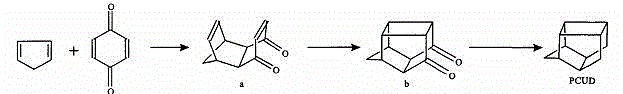

Method used

Image

Examples

Embodiment 1

[0029] ①Weigh 3g of urea and 6.5g of formaldehyde (37%) and dissolve it in 20g of deionized water. The stirring speed is 400 rpm and stirring for 5 minutes to obtain a urea-formaldehyde resin prepolymer. ②Then weigh 4g of urea-formaldehyde resin prepolymer and add it to the reactor. The stirring rate is 800 rpm. First, weigh 0.3g of sodium dodecyl sulfate (SDS) into the reactor and stir for 10 minutes to obtain urea-formaldehyde resin. wall material. ③ 9g of pentacycloundecane and 0.3g of SDS were added to 30g of deionized water, the stirring speed was 500 rpm, and the mixture was stirred for 10 minutes to obtain an emulsion. ④ Under the condition that the stirring rate is 800 rpm, drop the emulsion into the urea-formaldehyde resin wall material, the reaction temperature rises to 60 ℃, after 50 minutes of reaction, the temperature is lowered to 25 ℃, and the pH value of the solution is adjusted with concentrated sulfuric acid to 1 to obtain urea-formaldehyde resin-type microc...

Embodiment 2

[0031] ① Dissolve 3.3g of urea and 7.0g of formaldehyde (37%) in 20g of deionized water, stir at a speed of 500 rpm, and stir for 5 minutes to obtain a urea-formaldehyde resin prepolymer. ②Then weigh 5g of urea-formaldehyde resin prepolymer and add it to the reactor. The stirring speed is 900 rpm. First, weigh 0.5g of sodium dodecyl sulfate (SDS) and add it to the reactor and stir for 10 minutes to obtain urea-formaldehyde resin. wall material. ③ Add 10 g of pentacycloundecane and 0.5 g of SDS to 35 g of deionized water, the stirring speed is 550 rev / min, and the mixture is stirred for 15 minutes to obtain an emulsion. ④ Under the condition that the stirring rate is 900 rpm, drop the emulsion into the urea-formaldehyde resin wall material, the reaction temperature rises to 65°C, and after 55 minutes of reaction, the temperature is lowered to 25°C, and the pH value of the solution is adjusted with concentrated sulfuric acid. to 1.5 to obtain urea-formaldehyde resin-type microc...

Embodiment 3

[0033] ① Dissolve 3.6g of urea and 7.5g of formaldehyde (37%) in 30g of deionized water, stir at a speed of 600 rpm, and stir for 10 minutes to obtain a urea-formaldehyde resin prepolymer. ②Then 6g of urea-formaldehyde resin prepolymer was weighed and added to the reactor. The stirring rate was 1000 rpm. First, 0.44g of sodium dodecyl sulfate (SDS) was weighed into the reactor and stirred for 15 minutes to obtain urea-formaldehyde resin. wall material. ③ Add 12 g of pentacycloundecane and 0.89 g of SDS to 40 g of deionized water, the stirring speed is 600 rpm, and the mixture is stirred for 20 minutes to obtain an emulsion. ④ Under the condition that the stirring rate is 900 rpm, drop the emulsion into the urea-formaldehyde resin wall material, the reaction temperature rises to 70 ℃, after 65 minutes of reaction, the temperature is lowered to 25 ℃, and the pH value of the solution is adjusted with concentrated sulfuric acid To 2, urea-formaldehyde resin-type microcapsules are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com