Surface acoustic wave resonator type vibration sensor and surface acoustic wave resonator type vibration detection system

A vibration sensor, surface acoustic wave technology, applied in the measurement of ultrasonic/sonic/infrasonic waves, instruments, measuring devices, etc., can solve the problem of large occupied volume of the surface acoustic wave sensor, and achieve small occupied space, cost saving, and simple circuit structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

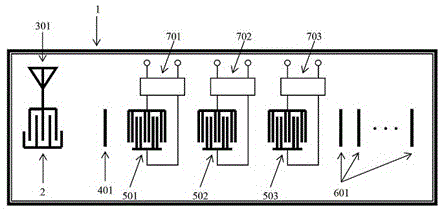

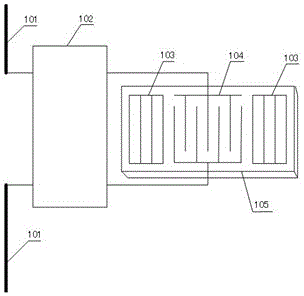

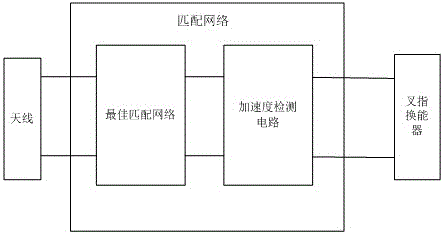

[0032] Embodiment one, see figure 2 As shown, the present embodiment provides a surface acoustic wave resonator type vibration sensor, including a first antenna 101, a matching network 102, a reflection grid 103, and an interdigital transducer 104, at least the reflection grid 103, and an interdigital transducer The energy device 104 is arranged on the piezoelectric substrate 105, see image 3 As shown, the matching network 102 includes an optimal matching network composed of at least one capacitor and at least one inductor. The optimal matching network is also connected in parallel with an acceleration detection circuit. The acceleration detection circuit includes several branches connected in parallel. The number of branches incorporated into the optimal matching network is different. The working principle of the surface acoustic wave resonator type vibration sensor of the present embodiment is: the first antenna 101 receives the excitation signal, by adding an acceleratio...

Embodiment 2

[0034] Embodiment 2, this embodiment provides a schematic circuit diagram of a surface acoustic wave resonator type vibration sensor, see image 3 As shown, the optimal matching network is composed of the first capacitor C0 and the first inductor L0 connected in parallel, and the acceleration detection circuit is connected in parallel at both ends of the parallel circuit composed of the optimal matching network.

[0035] As a preferred embodiment, each branch of the acceleration detection circuit is provided with an elastic switch element. see Figure 4 As shown, the elastic switch element is a spring or a reed, and when the acceleration in the deformation direction of the spring or the reed reaches a threshold value, the spring or the reed deforms and conducts the branch where it is located. Of course, the acceleration threshold at which the spring or reed can make the branch where it is connected is fixed, and the thresholds of the elastic switching elements on each branch ...

Embodiment 3

[0037] Embodiment three, this embodiment provides a schematic circuit diagram of a surface acoustic wave resonator type vibration sensor, see Figure 5 As shown, the optimal matching network is composed of a first capacitor C1 and a first inductor L1 connected in parallel, and the acceleration detection circuit is connected in parallel at both ends of the first inductor L1.

[0038] In this embodiment, the acceleration detection circuit includes several parallel branches, wherein the first branch from left to right is connected in series by an elastic switching element K1 and a capacitor C2, and the second branch is connected by an elastic switching element K2 It is connected in series with an inductor L2, and the third branch is connected in series with a capacitor C3 and an inductor L3 by an elastic switching element K3. In this embodiment, the springs in the passive acceleration sensor are selected as the elastic switch elements K1-K3. The elastic switch elements K1-K3 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com