Test liquid for detecting cleaning effect of wet flat steel plate before electrolytic tin plating and detection method

A technology of cleaning effect and testing liquid, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc., can solve the problem of undetectable cleaning effect of wet flat steel plate before electroplating, etc. Achieve the effect of low work intensity, simple preparation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

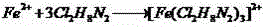

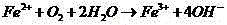

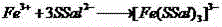

Method used

Image

Examples

Embodiment 1

[0034] The test solution for detecting the cleaning effect of the wet flat steel plate before tinning is composed of the following according to the mass concentration: o-phenanthroline 1.2g / L, NaCl 2.0g / L, and the balance is deionized water.

[0035] The preparation method of the test solution of the present invention: Weigh 1.2g o-phenanthroline and 2.0g NaCl, put them into a 1L container, add deionized water to 1L, and stir evenly.

[0036] The method for detecting the cleaning effect of wet flat steel plate before electro-tinning comprises the following steps:

[0037] a. Weigh 1.2g o-phenanthroline and 2.0g NaCl, put it into a 1L container, add deionized water to 1L, stir evenly to prepare a test solution, and place it for use;

[0038] b. Put the two steel plates to be tested, both of which are 100mm*100mm in size, on the test bench after cleaning, drop 4 drops of test liquid respectively and start timing. The diameter of the spherical crown of the water drop is about 1.5...

Embodiment 2

[0041] The test solution for detecting the cleaning effect of the wet flat steel plate before electro-tinning consists of the following components according to the mass concentration: o-phenanthroline 1.0g / L, NaCl 3.0g / L, and the balance is deionized water.

[0042] The preparation method of the test solution of the present invention: weigh 1.0 g o-phenanthroline and 3.0 g NaCl, put them into a 1 L container, add deionized water to 1 L, and stir evenly.

[0043] The method for detecting the cleaning effect of wet flat steel plate before electro-tinning comprises the following steps:

[0044] a. Weigh 1.0g o-phenanthroline and 3.0g NaCl, put them into a 1L container, add deionized water to 1L, stir evenly to prepare a test solution, and place it for use;

[0045] b. Put the two steel plates to be tested, both of which are 100mm*100mm in size, on the test bench after cleaning, drop 4 drops of test liquid respectively and start timing. The diameter of the spherical crown of the w...

Embodiment 3

[0048] The test solution for detecting the cleaning effect of the wet flat steel plate before electro-tinning is composed of the following according to the mass concentration: sulfosalicylic acid 1.2g / L, KCl 2.0g / L, and the balance is deionized water.

[0049] The preparation method of the test solution of the present invention: weigh 1.2g of sulfosalicylic acid and 2.0g of KCl, put them into a 1L container, add deionized water to 1L, and stir evenly.

[0050] The method for detecting the cleaning effect of wet flat steel plate before electro-tinning comprises the following steps:

[0051] a. Weigh 1.2g sulfosalicylic acid and 2.0g KCl, put them into a 1L container, add deionized water to 1L, stir evenly to prepare a test solution, and place it for use;

[0052] b. Put the two steel plates to be tested, both of which are 100mm*100mm in size, on the test bench after cleaning, drop 4 drops of test liquid respectively and start timing. The diameter of the spherical crown of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com