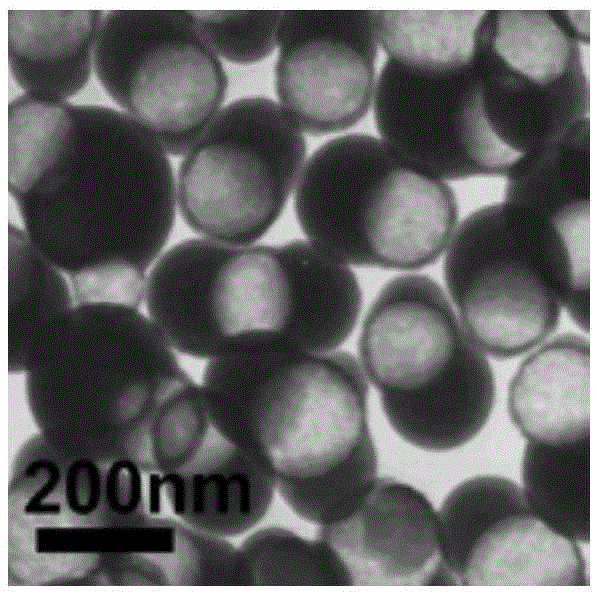

Preparing method for asymmetric hollow microspheres based on polymer template particles

A hollow microsphere and polymer technology, which is applied in the field of preparation of asymmetric hollow microspheres, can solve the problems of difficult large-scale production, complex and tedious synthesis process, etc., and achieves the effects of mild experimental conditions, efficient preparation method and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

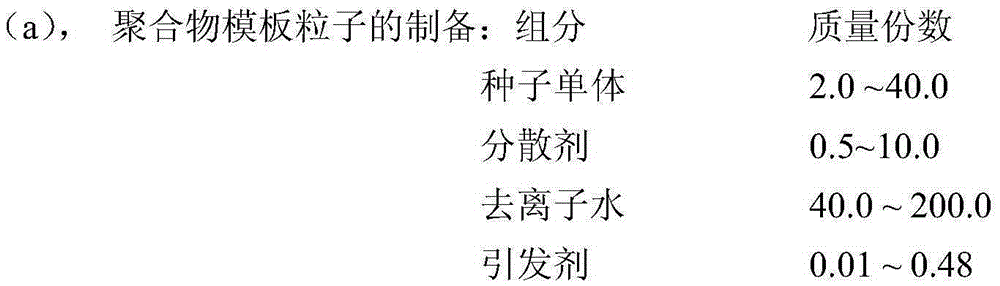

[0021]

[0022] According to the above proportions, the pre-measured deionized water, the seed monomer styrene, the dispersant polyvinylpyrrolidone, and the initiator benzoyl peroxide are added into the reactor together, and the stirring is started, and the whole process is passed through. Nitrogen, reflux condensation, and polymer template particles are obtained when the system reaches 70 °C and polymerized for 10 hours;

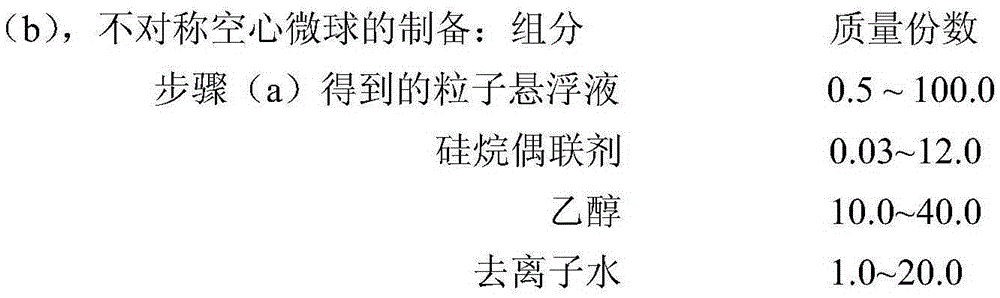

[0023]

[0024] A certain amount of the polymer particle suspension (25.0g) obtained in the step (a) was mixed with a certain proportion of ethanol / water (18.0g / 2.0g) solution, and a certain amount of 5mol / L NaOH solution was used to make the system The pH was adjusted to 14, and after stirring for ten minutes, the silane coupling agent 3-mercaptopropyltriethoxysilane was rapidly added, and the stirring was continued at 50° C. for 3 hours to obtain asymmetric silica hollow microspheres.

[0025] When the polymer particles are mixed with the silane cou...

Embodiment example 2-5

[0028] In Example 2-5, the amount of the silane coupling agent was changed to 1.0g, 3.0g, 4.0g, and 8.0g, respectively. The remaining steps were the same as Example 1.

Embodiment example 6-7

[0030] In Example 6-7, the silane coupling agent was changed to tetraethoxysilane and 3-aminopropyltriethoxysilane, respectively, and the remaining steps were the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com