Copper-based alloy brazing filler metal containing trace Ge, preparation method and brazing method thereof

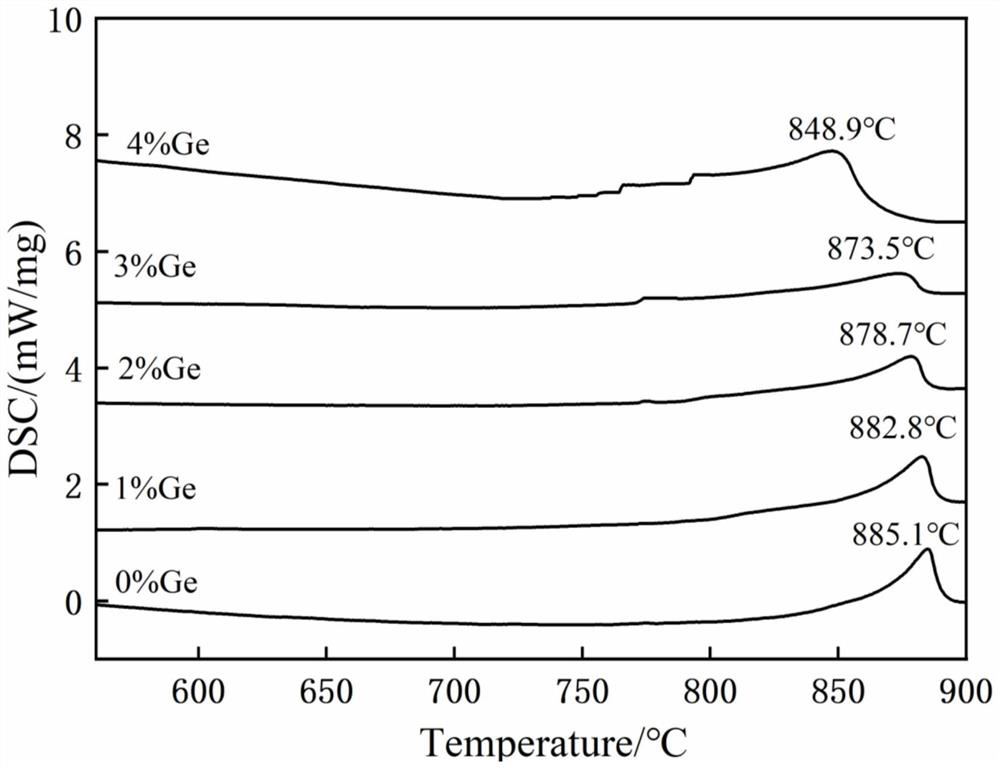

A technology for copper-based alloys and alloy brazing filler metals, which can be applied to cleaning methods using liquids, metal processing equipment, cleaning methods and utensils, etc., and can solve the problems of poor fluidity, low climbing height, and poor wettability of copper-based brazing filler metals. Achieve the effect of enhanced corrosion resistance, high shear strength and lower melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of a Ge-containing Cu-based alloy brazing filler metal of the present embodiment and a method for brazing the brazing filler metal, the steps are:

[0042] (1) Take Cu, Sn, Ti, Ga, Ge metal ingots and use 320#, 600# metallographic sandpaper to polish off impurities such as surface oxides, use an electronic balance to weigh 6.8g Cu, 2g Sn, 1g Ti, 0.1 g Ga and 0.1g Ge, put the weighed metal ingot in a beaker, add acetone to clean under ultrasonic for 5-10min, then add alcohol to ultrasonically clean for 5-10min, and finally blow dry;

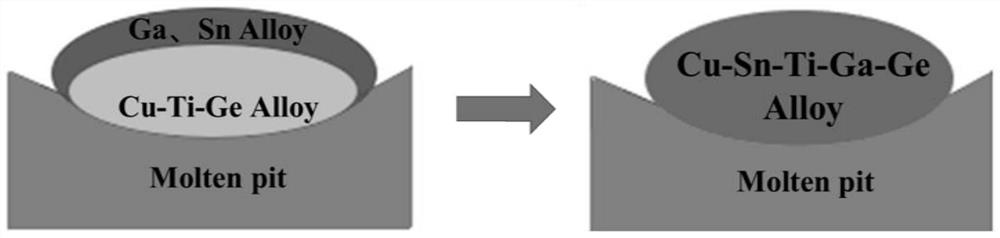

[0043] (2) First place the dried spare Cu, Ti and Ge metal ingots in a vacuum electric arc furnace, fill in high-purity Ar gas as a protective gas after vacuuming, and melt for 2 to 3 times at a current of 2A to 5A;

[0044] (3) Take out the Cu-Ti-Ge alloy, place Sn and Ga in the melting pit, then add the Cu-Ti-Ge alloy, and then vacuumize and heat it with a tungsten melting arc at a current of 2A to 5A. Alloy smelting...

Embodiment 2

[0051] A preparation method of a Ge-containing Cu-based alloy brazing filler metal of the present embodiment and a method for brazing the brazing filler metal, the steps are:

[0052] (1) Take Cu, Sn, Ti, Ga, Ge and use 320#, 600# metallographic sandpaper to polish off impurities such as surface oxides, and weigh 6.7g Cu, 2g Sn, 1g Ti, 0.1g Ga and 0.2 g Ge, put the weighed metal ingot in a beaker, add acetone to clean under ultrasonic for 5-10min, then add alcohol to ultrasonically clean for 5-10min, and finally blow dry;

[0053] (2) First place the dried spare Cu, Ti and Ge metal ingots in a vacuum electric arc furnace, fill in high-purity Ar gas as a protective gas after vacuuming, and melt for 2 to 3 times at a current of 2A to 5A to obtain Cu-Ti-Ge alloy;

[0054] (3) Take out the Cu-Ti-Ge alloy, place Sn and Ga in the melting pit, then add the Cu-Ti-Ge alloy, and then vacuumize and heat it with a tungsten melting arc at a current of 2A to 5A. The alloy is smelted for 2...

Embodiment 3

[0061] (1) Take Cu, Sn, Ti, Ga, Ge metal ingots and use 320#, 600# metallographic sandpaper to polish off impurities such as surface oxides, use an electronic balance to weigh 6.6g Cu, 2g Sn, 1g Ti, 0.1 g Ga and 0.3g Ge, put the weighed metal ingot in a beaker, add acetone to clean under ultrasonic for 5-10min, then add alcohol to ultrasonically clean for 5-10min, and finally blow dry;

[0062] (2) First place the dried spare Cu, Ti and Ge metal ingots in a vacuum electric arc furnace, fill in high-purity Ar gas as a protective gas after vacuuming, and melt for 2 to 3 times at a current of 2A to 5A to obtain Cu-Ti-Ge alloy;

[0063] (3) Take out the Cu-Ti-Ge alloy, place Sn and Ga in the melting pit, then add the Cu-Ti-Ge alloy, and then vacuumize and heat it with a tungsten melting arc at a current of 2A to 5A. Alloy smelting 2 to 3 times; after cooling to room temperature, take out the alloy solder Cu-Sn-Ti-Ga-Ge from the vacuum electric arc furnace;

[0064] (4) Sampling:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com