Catalyst for catalytically removing environmental pollutants at low temperature and preparation method thereof

A technology of catalysts and composite oxides, which is applied in the field of low-temperature catalytic removal of environmental pollutants and its preparation. It can solve the problems of high cost and complicated process procedures, and achieve the effects of low price, economical and simple preparation process, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

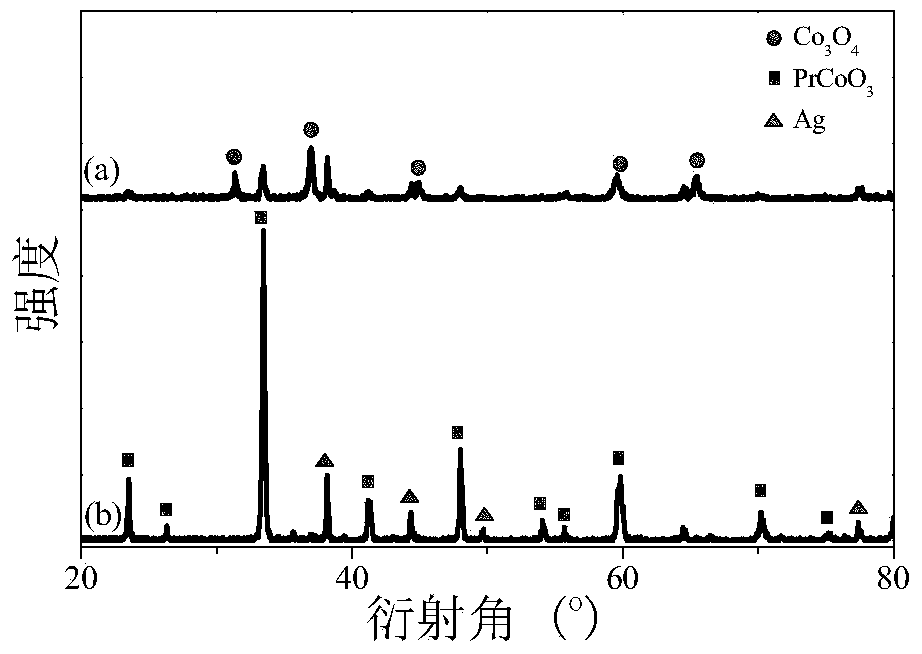

[0034] This embodiment relates to a catalyst capable of catalytically removing various environmental pollutants at low temperature and its preparation method; the preparation method includes the following steps:

[0035] 1. Use Co(NO 3 ) 3 ·6H 2 O as cobalt source, take 2.91g, use Pr(NO 3 ) 3 6H 2O as the source of praseodymium, take 3.39g, use silver nitrate as the silver source, take 1.02g, weigh 20g of citric acid monohydrate, put it into a beaker, add 150mL of deionized water and stir to disperse to form a solution.

[0036] 2. The solution obtained above was evaporated to dryness with stirring at 80° C., and dried in an oven for 12 hours.

[0037] 3. Put the powdered solid sample into a corundum crucible with a volume of 200mL, then place the sample-filled crucible in a muffle furnace, raise the temperature to 500°C at a rate of 10°C / min, and keep it warm for 4h. After cooling, take it out and place it in an agate mortar for grinding, then put the sample-filled porc...

Embodiment 2

[0042] This embodiment relates to a catalyst capable of catalytically removing various environmental pollutants at low temperature and its preparation method; the preparation method includes the following steps:

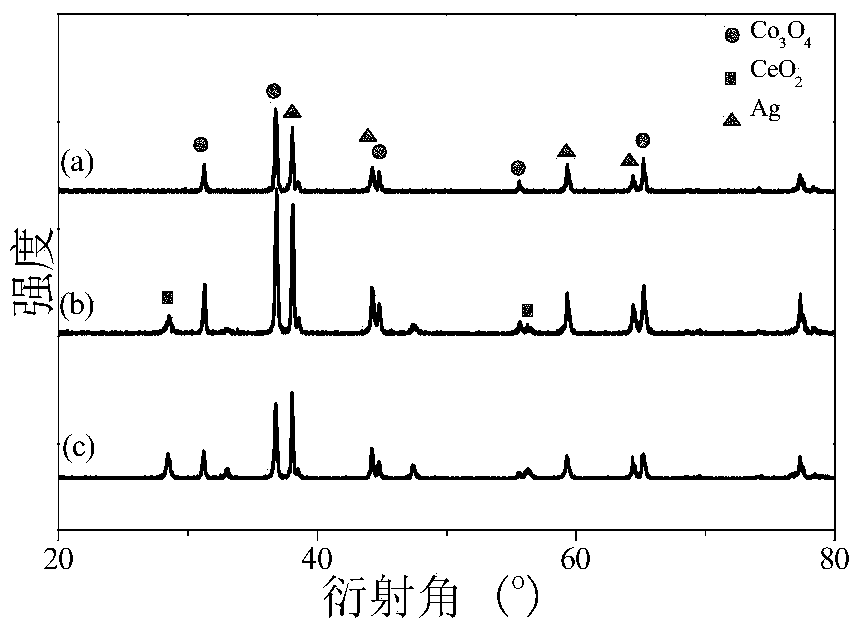

[0043] 1. Use C 4 h 6 COO 4 4H 2 O as cobalt source, take 2.431g, Ce(NO 3 ) 3 6H 2 O as the cerium source, take 0.0868g and use silver nitrate as the silver source, take 0.17g, weigh 20g of citric acid monohydrate, put it into a 200ml beaker, add 100mL of deionized water to dissolve the above powder.

[0044] 2. The solution obtained above was evaporated to dryness with stirring at 80° C., and dried in an oven for 12 hours.

[0045] 3. Put the powdered solid sample into a corundum crucible with a volume of 200mL, then place the sample-filled crucible in a muffle furnace, raise the temperature to 900°C at a rate of 10°C / min, and keep it warm for 4h. After cooling, take it out and put it in an agate mortar for grinding, then put the sample-filled porcelain cruci...

Embodiment 3

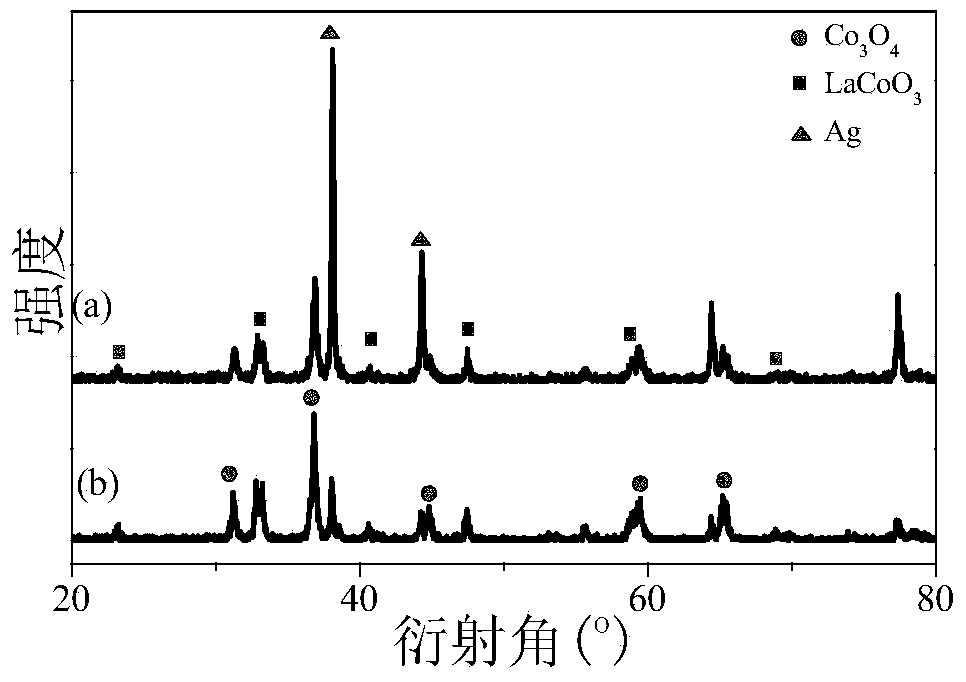

[0050] This embodiment relates to a catalyst capable of catalytically removing various environmental pollutants at low temperature and its preparation method; the preparation method includes the following steps:

[0051] 1. Use Co(NO 3 ) 3 ·6H 2 O as cobalt source, take 5.82g, use Ce(NO 3 ) 3 6H 2 O as a cerium source, take 10.861g, place in a beaker, add 150ml of deionized water, and dissolve the above powder. Prepare another 1mol / L Na 2 CO 3 250ml of the solution is ready for use.

[0052] 2. Add 1mol / L Na 2 CO 3 The solution was added dropwise to the mixed solution of cobalt nitrate and cerous nitrate in a stirring state, and the pH value of the solution was monitored by a pH meter. When the pH stabilized at 8, the dropwise addition was stopped.

[0053] 3. After the obtained precipitate was aged for 10 hours, it was washed with deionized water and suction-filtered 5 times, and the precipitate was dried in an oven at 100°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com