Method for preparing carbon nanotube/glass fiber nano-micron compound powder

A carbon nanotube and composite powder technology, which is applied in the field of glass fiber-based nano-micron powder and its preparation, can solve the problems of complex process, high cost, and small output, and achieve the effect of simple process, low cost, and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Ultrasonic dispersion of 4g glass fiber in 50mL absolute ethanol was transferred to a three-necked flask and stirred; 0.2g acidified carbon nanotubes were ultrasonically dispersed in a hydroalcoholic solution (10mL water + 5mL ethanol), also transferred to a three-necked flask and heated to At 80°C, add 1.5mL hydrochloric acid solution into the flask to adjust the pH of the system to 5.0, and continue stirring for 30min. Add a certain amount of 0.1mL KH550 and 0.5mLTEOS ethanol solution 5mL dropwise to the above system, react for 6h, cool down to room temperature, filter the product with suction, wash with 20mL water and 20mL absolute ethanol, and finally put the product at 100°C Dry in an oven for 4 hours to obtain a sample.

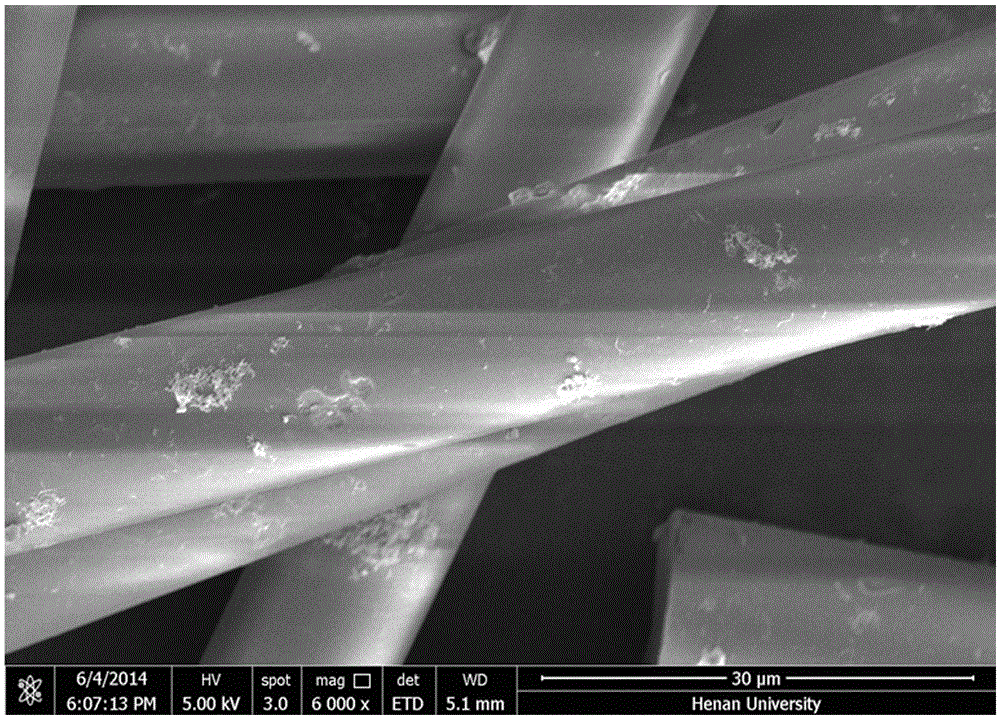

[0037] Observed under the scanning electron microscope, as figure 1 shown. It can be seen that the carbon nanotubes are not uniformly distributed on the surface of the glass fiber, and some are distributed in an island shape, and the carbon na...

Embodiment 2

[0039] Ultrasonic dispersion of 4g glass fiber in 50mL absolute ethanol was transferred to a three-necked flask and stirred; 0.8g acidified carbon nanotubes were ultrasonically dispersed in a hydroalcoholic solution (10mL water + 5mL ethanol), also transferred to a three-necked flask and heated to At 85°C, add 2 mL of ammonium chloride aqueous solution to the flask to adjust the pH of the system to 6.0, and continue stirring for 30 min. Add 5 mL of ethanol solution of 0.25 mL KH550 and 1.25 mL LTEOS to the above system dropwise, react for 6 hours, cool down to room temperature, filter the product with suction, wash with 20 mL of water and 20 mL of absolute ethanol, and finally dry the product in an oven at 100°C Dry for 4 hours to obtain a sample.

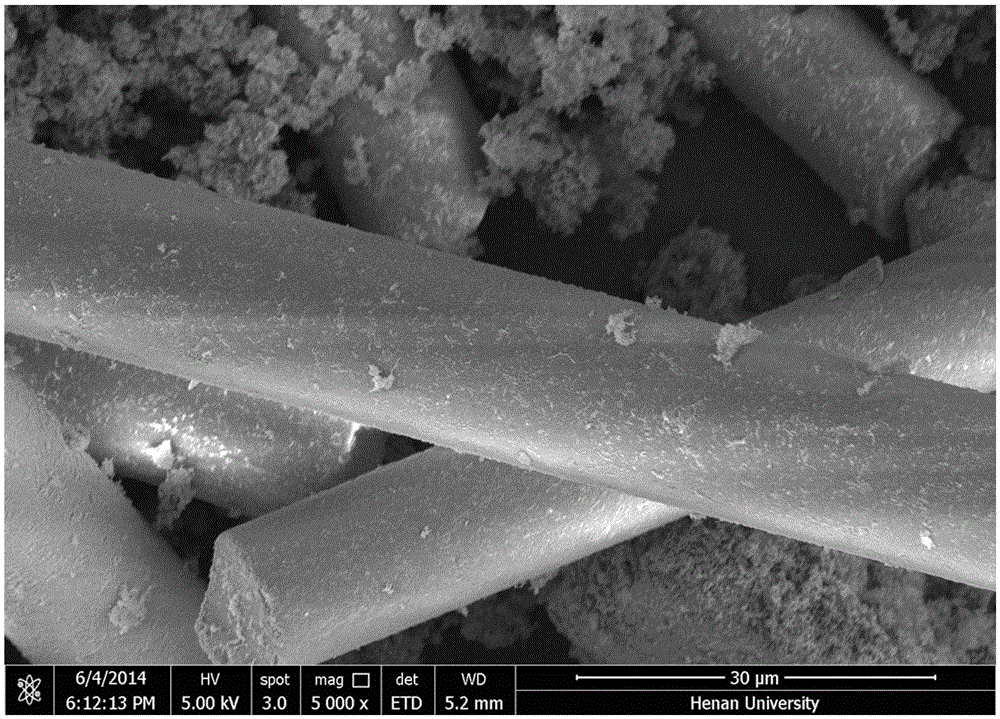

[0040] Observed under the scanning electron microscope, as figure 2 shown. It can be seen that more carbon nanotubes are evenly distributed on the surface of the glass fiber.

Embodiment 3

[0042] Ultrasonic dispersion of 4g glass fiber in 50mL absolute ethanol was transferred to a three-necked flask and stirred; 0.2g acidified carbon nanotubes were ultrasonically dispersed in a hydroalcoholic solution (10mL water + 5mL ethanol), also transferred to a three-necked flask and heated to At 60°C, add 1 mL of ethylene glycol amine solution to the flask to adjust the pH of the system to 7.0, and continue stirring for 30 min. Add 5 mL of ethanol solution of 0.25 mL KH550 and 1.25 mL LTEOS to the above system dropwise, react for 6 hours, cool down to room temperature, filter the product with suction, wash with 20 mL of water and 20 mL of absolute ethanol, and finally dry the product in an oven at 100°C Dry for 4 hours to obtain a sample.

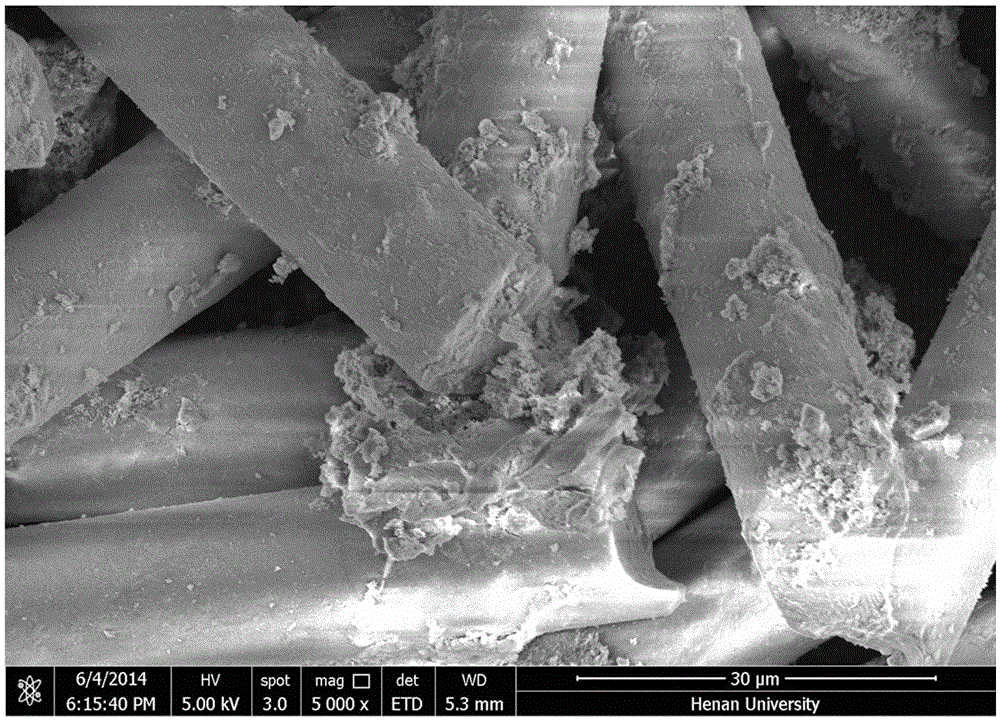

[0043] Observed under the scanning electron microscope, as image 3 shown. The carbon nanotubes are seriously agglomerated, and they are coated on the surface of the glass fiber together with polysilicon, so that the surface of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com