A kind of high pressure water explosion and co 2 Coalbed methane displacement and drainage technology combined with fracturing

A high-pressure water and CO2 technology, applied in mining fluids, mining equipment, earthwork drilling and mining, etc., can solve the problems of insignificant anti-reflection effect, less consideration of the influence of ground stress, and unstable diversion capacity, etc., and achieve excellent transfer efficiency , Solve the effect of permanent storage and quick cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

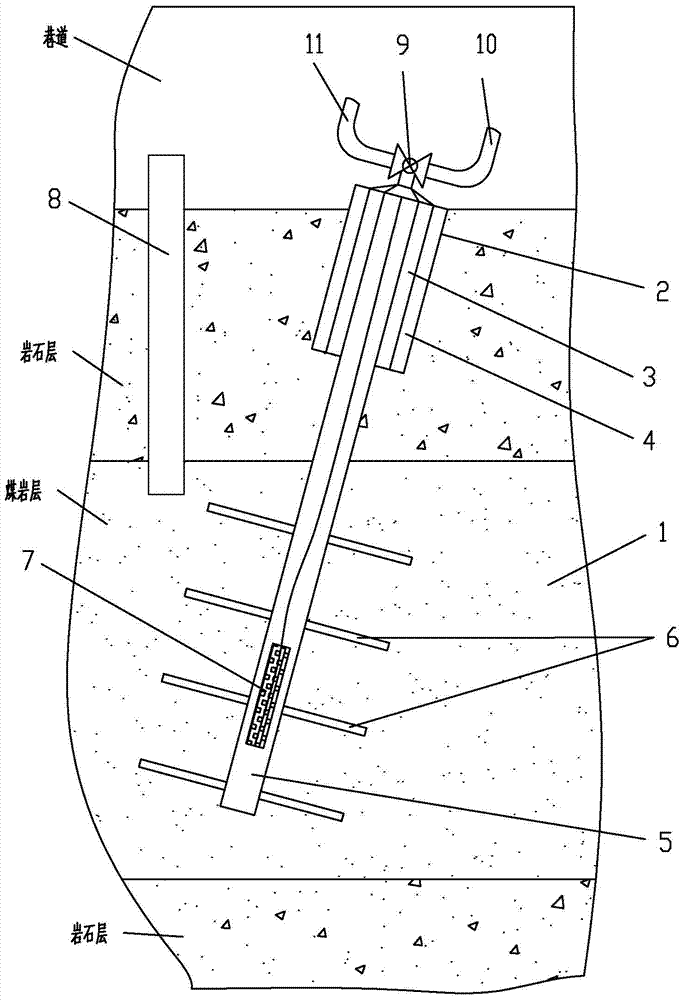

[0025] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

[0026] see figure 1 , a high-pressure water explosion with CO 2 The coalbed methane displacement and drainage technology combined with fracturing includes the following steps:

[0027] The first step is to determine the state of in-situ stress: determine the in-situ stress state of the coal rock layer 1 through the in-situ stress test;

[0028] The second step, drilling and sealing of the sealing section: use mechanical or hydraulic drilling methods to form the sealing section drilling 2 along the direction perpendicular to the maximum principal stress of the coal rock layer 1, and install the casing 3, on the outer wall of the casing 3 Seal with cement mortar 4 between the hole wall of the hole 2 in the sealing section, and maintain for more than 72 hours to form the sealing section;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com