Nitrogen-doped carbon nanotube/ carbonitride composite material preparation method and application

A nitrogen-doped carbon, composite material technology, applied in biochemical fuel cells, electrical components, battery electrodes, etc., to achieve the effects of easy preparation, strong activity, and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1: Preparation of Nitrogen-doped Carbon Nanotubes / Carbon Nitride Composite

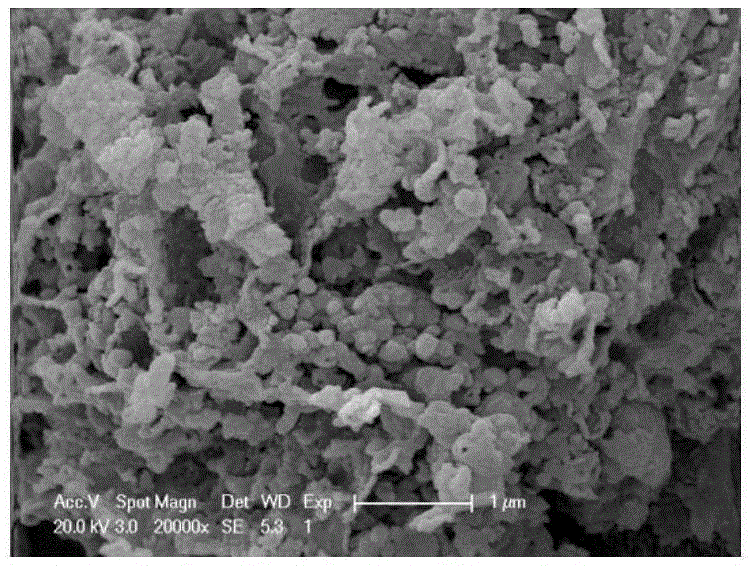

[0038] Mix nitrogen-doped carbon nanotubes and solid cyanamide powder at a mass ratio of 1:50, place them in a mortar and grind for 1 hour and mix well until uniform. The mixed nitrogen-doped carbon nanotube / cyanamide powder was placed in a tube furnace, and calcined at 550° C. for 2 h. After the reaction is completed, the composite material is obtained. The composite material is washed several times with ethanol and ultrapure water, centrifuged, and then dried to form a nitrogen-doped carbon nanotube / carbon nitride composite material. The SEM morphology is as follows:figure 1 as shown, figure 1 It is the SEM topography image of the nitrogen-doped carbon nanotube / carbon nitride composite material of the embodiment of the present invention.

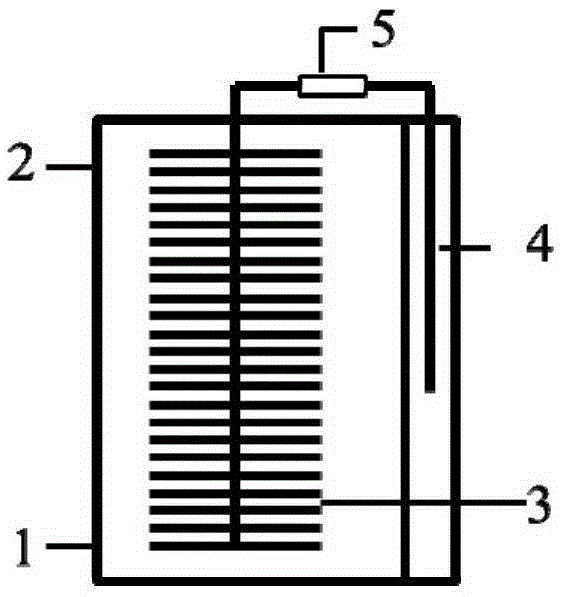

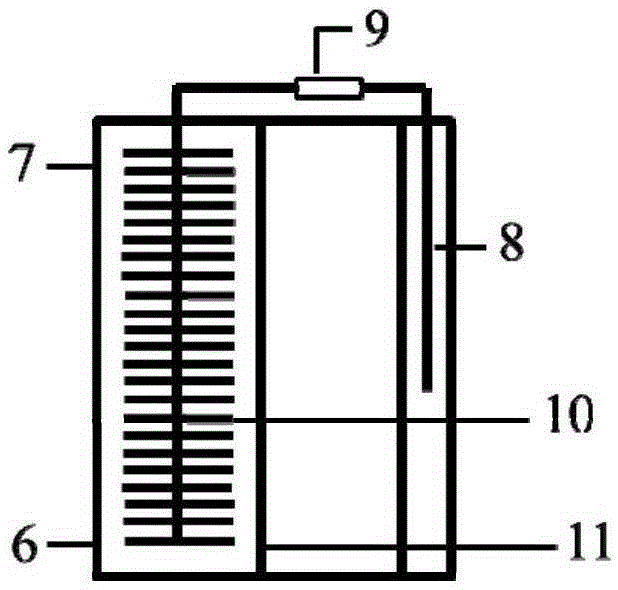

[0039] Step 2: Electrode Preparation

[0040] Mix the nitrogen-doped carbon nanotube / carbon nitride composite material, the conductive material carb...

Embodiment 2

[0047] The difference between this example and Example 1 is that in the first step of preparing the nitrogen-doped carbon nanotube / carbon nitride composite material, nitrogen-doped carbon nanotubes and solid cyanamide powder are mixed at a mass ratio of 1:10. Other steps and parameters are the same as in Example 1.

[0048] The performance of microbial fuel cells with different catalytic electrodes is shown in Table 2.

[0049] Table 2 Performance comparison of single-chamber microbial fuel cells with different catalytic electrodes

[0050]

[0051] It can be seen from Table 2 that nitrogen-doped carbon nanotubes / carbon nitride composites are used as oxygen reduction catalysts for single-chamber microbial fuel cells, and have catalytic activity and stability comparable to conventional Pt / C catalysts, indicating that they have Potential advantages of replacing Pt / C catalysts.

Embodiment 3

[0053] The difference between this example and Example 1 is that in the first step of preparing the nitrogen-doped carbon nanotube / carbon nitride composite material, nitrogen-doped carbon nanotubes and solid cyanamide powder are mixed at a mass ratio of 1:20. Other steps and parameters are the same as in Example 1.

[0054] The performance of microbial fuel cells with different catalytic electrodes is shown in Table 3.

[0055] Table 3 Performance comparison of single-chamber microbial fuel cells with different catalytic electrodes

[0056]

[0057] It can be seen from Table 3 that nitrogen-doped carbon nanotubes / carbon nitride composites are used as oxygen reduction catalysts for single-chamber microbial fuel cells, and have catalytic activity and stability comparable to conventional Pt / C catalysts, indicating that they have Potential advantages of replacing Pt / C catalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com