Mulberry active phenolic compound and pollution-free extraction and purification method thereof

A purification method and compound technology, applied in cosmetics, food science, drug combination and other directions, can solve the problems of high cost, complex equipment, high consumption of organic reagents, etc., to achieve the effect of retention, maintenance of content and activity, and easy breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

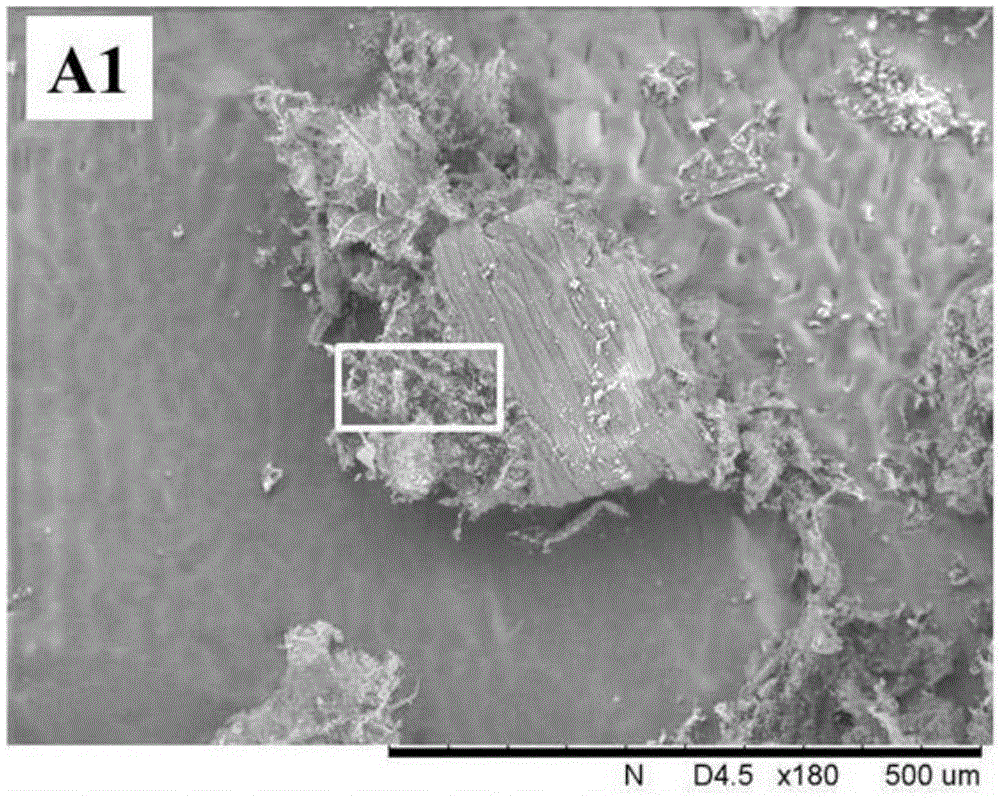

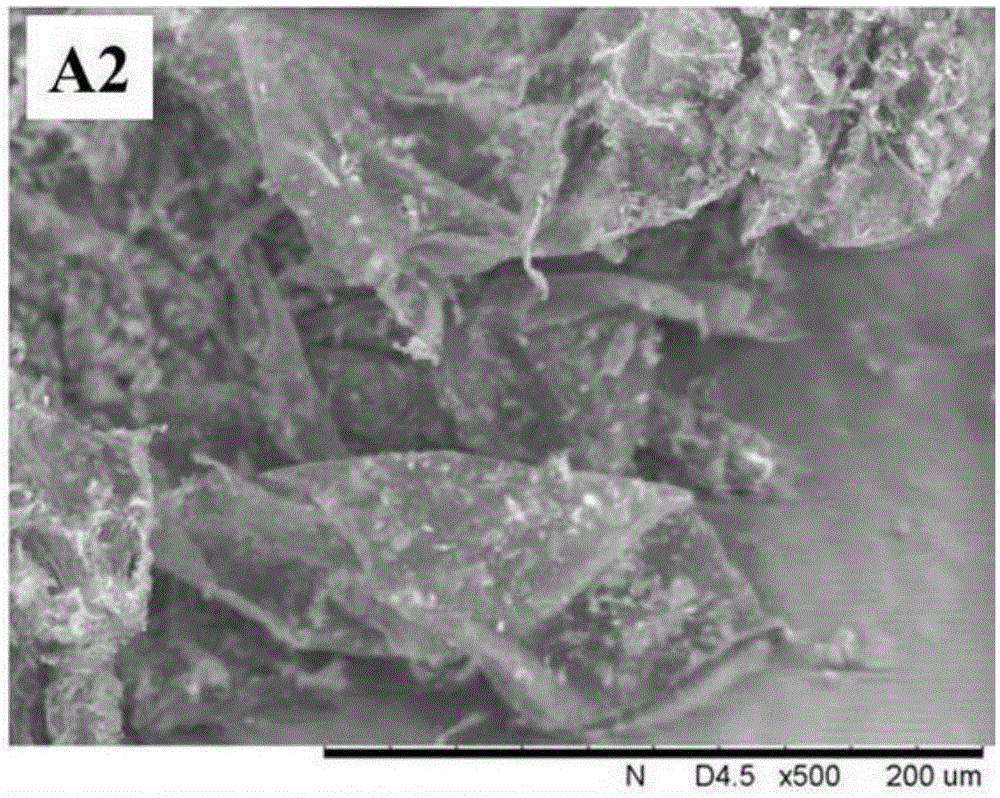

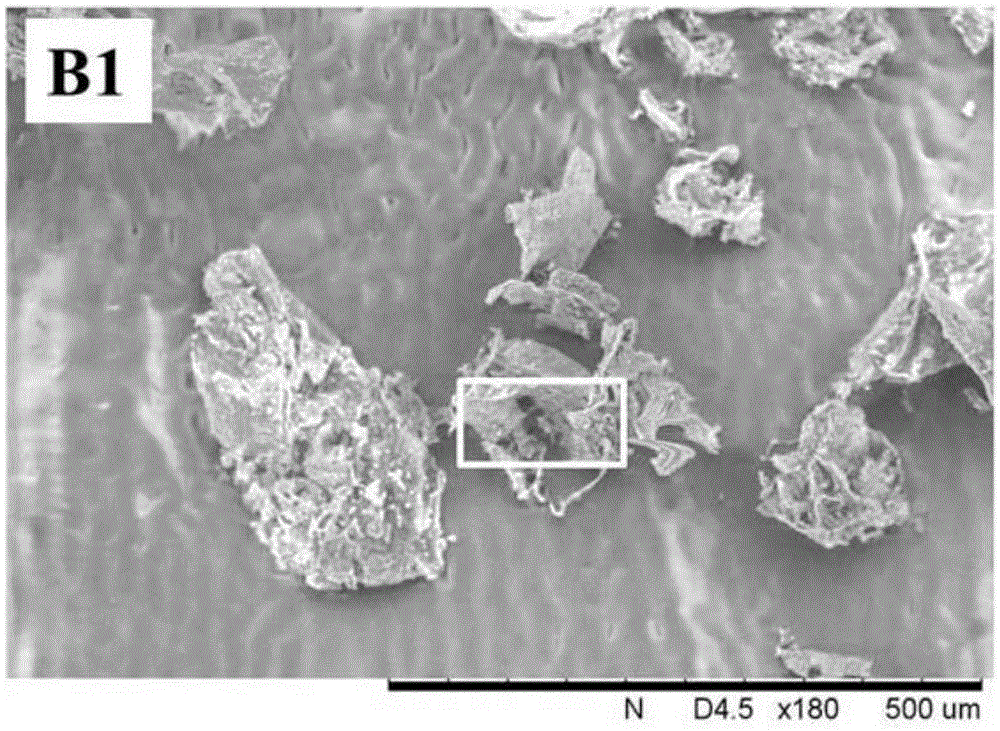

Image

Examples

Embodiment 1

[0051] Take a portion of frozen mulberries, without thawing, first inactivate the enzymes with microwave (vent hole is reserved on the packaging bag) (600W, 1min), and then inactivate the enzymes with steam for a second time (3min). Mix mulberries with 4 times the volume of ice water, and pre-crumble in a colloid mill (1.5Kw) for 3 minutes. The resulting mixture was centrifuged (8000g, 10min), and the supernatant (primary water extract) was collected for later use. Use 10% food-grade acidified ethanol aqueous solution (containing 0.1% citric acid) as the extractant of residual polyphenols (according to 1:3 solid-liquid ratio), and avoid light and sonicate (500W, 40KHz) for 40min at a temperature of 25°C. The ultrasonic extract was centrifuged (3000g, 10min), and the supernatant was concentrated under reduced pressure at 35°C for 20min to obtain a concentrated solution under reduced pressure, which was collected for later use. Mix the initial water extract with the decompressi...

Embodiment 2

[0056] Embodiment 2 (compared with conventional high-concentration organic reagent extraction method)

[0057] Take a portion of frozen mulberry without thawing and directly inactivate the enzyme with microwave (reserve a vent hole on the packaging bag) (500W, 2min), then inactivate the enzyme with steam for a second time (3min), and then mix it with 2 times the volume of pure water. The mixture was crushed in a colloid mill (JM‐65, Shanghai Duoyuan Machinery Co., Ltd.) for 3 min, and the obtained mulberry suspension was centrifuged at room temperature (8000 g, 10 min), and the supernatant (primary extract) was collected. Mix the residue with 20% food-grade ethanol aqueous solution (containing 0.9% citric acid) (according to 1:12 solid-liquid ratio, w / v, according to the mass unit is kilogram, the volume unit is liter calculation), the obtained mixture is protected from light by ultrasonic (500W , 30KHz) 2.5h, temperature 40 ℃. The ultrasonic extract was centrifuged (3000g, 2...

Embodiment 3

[0062] Embodiment 3 (compared with conventional ultrasonic method)

[0063] Take a portion of frozen mulberry as raw material, directly inactivate the enzyme with microwave (reserve vent hole on the packaging bag) (500W, 4min), then inactivate the enzyme with steam for a second time (1min), then dilute and mix with 2 times ice water, put in the colloid Grinding in a mill (JM‐65, Shanghai Duoyuan Machinery Co.) for 5 min, centrifuging the obtained slurry mixture (8000 g, 20 min), and collecting the supernatant for later use. Mix the remaining residue with 25% food-grade acidified ethanol (containing 0.7% citric acid) (according to 1:15 solid-liquid ratio, w / v, calculated as kilogram by mass and liter by volume), and avoid Photo-ultrasound (500W, 30KHz) for 2.5h, using circulating tap water to maintain the material temperature at 28±2°C during the ultrasonic process. The ultrasonic extract was centrifuged (3000g, 10min), and the supernatant was concentrated under reduced pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com