Manufacturing method for flaky silver powder with high flake rate and narrow particle size distribution

A technology of particle size distribution and flaky silver powder, applied in the field of preparation of flaky silver powder, can solve the problems of uneven particle size, cold welding agglomeration, low flaky rate of flaky silver powder, etc., achieve narrow particle size distribution and avoid agglomeration , The effect of high flake rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

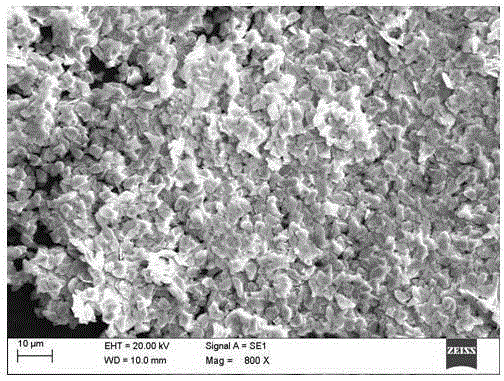

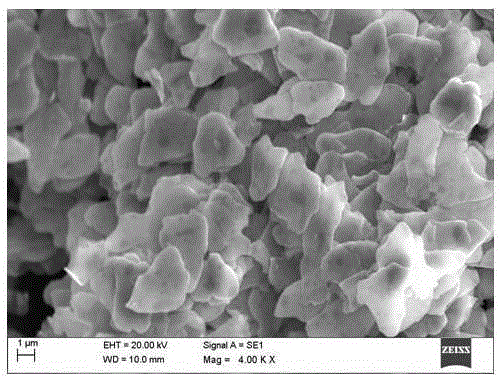

Image

Examples

Embodiment 1

[0018] A preparation method of flaky silver powder with high flaky rate and narrow particle size distribution. First, select the precursor spherical silver powder and ball milling balls to soak in the ball milling medium solvent, then add block type polymer dispersant, and then ultrasonicate at a certain temperature treatment to promote the dispersion of spherical silver powder on the surface of ball milling balls at the molecular level; in the process of ball milling, pre-grinding is carried out at first at a low speed, so that the silver powder and balls are evenly distributed in the ball milling tank, and then high-speed ball milling to obtain flakes Flake silver powder with high yield and narrow particle size distribution; the specific steps are as follows:

[0019] (1) Add ball milling aid oleic acid to the ball milling medium solvent ethanol, the amount of oleic acid added is 0.5% of the total mass of the spherical silver powder;

[0020] (2) Soak 0.2kg precursor spheric...

Embodiment 2

[0025] A preparation method of flaky silver powder with high flaky rate and narrow particle size distribution, the specific steps are as follows:

[0026] (1) Add stearic acid, a ball milling aid, to ethanol, and the amount of stearic acid added is 2% of the total mass of the spherical silver powder;

[0027] (2) Soak 25g of precursor spherical silver powder and 1000g of ball milling balls in the above solvent, then add block type polymer dispersant poly(vinylpyridine)-b-(methoxypolyethylene glycol acrylate), and then Ultrasonic treatment at 70°C for 10 minutes, wherein the mass ratio of spherical silver powder and ball milling medium solvent is 0.2:1, and the size range of ball milling balls is 2mm;

[0028] (3) Transfer the above-mentioned spherical silver powder, milling balls, milling medium solvent and milling aid to a 1L milling tank, and perform low-speed ball milling in a planetary ball mill at a milling speed of 50r / min to make the silver powder and milling balls in t...

Embodiment 3

[0032] A preparation method of flaky silver powder with high flaky rate and narrow particle size distribution, the specific steps are as follows:

[0033] (1) Add ball milling aid oleic acid amide to propanol, the amount of oleic acid amide added is 3% of the total mass of spherical silver powder;

[0034] (2) Soak 1kg of precursor spherical silver powder and 25kg of ball milling balls in the above solvent, then add block-type polymer dispersant poly(dimethylaminoethyl acrylate)-b-polyethylene glycol, and then Ultrasonic treatment for 60 minutes, wherein the mass ratio of spherical silver powder and ball milling medium solvent is 0.6:1, and the size range of ball milling balls is 0.1mm;

[0035] (3) Transfer the above-mentioned spherical silver powder, milling balls, milling medium solvent and milling aid to a 15L milling tank, and perform low-speed ball milling in a planetary ball mill at a milling speed of 120r / min to make the silver powder and milling balls in the milling t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com