R2Cu2O5 oxide material used for low-temperature magnetic refrigeration and preparation method thereof

A low-temperature magnetic refrigeration, r2cu2o5 technology, applied in the field of functional materials, can solve the problems of complex preparation process and high raw material price, and achieve the effects of simple process, simple preparation method and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

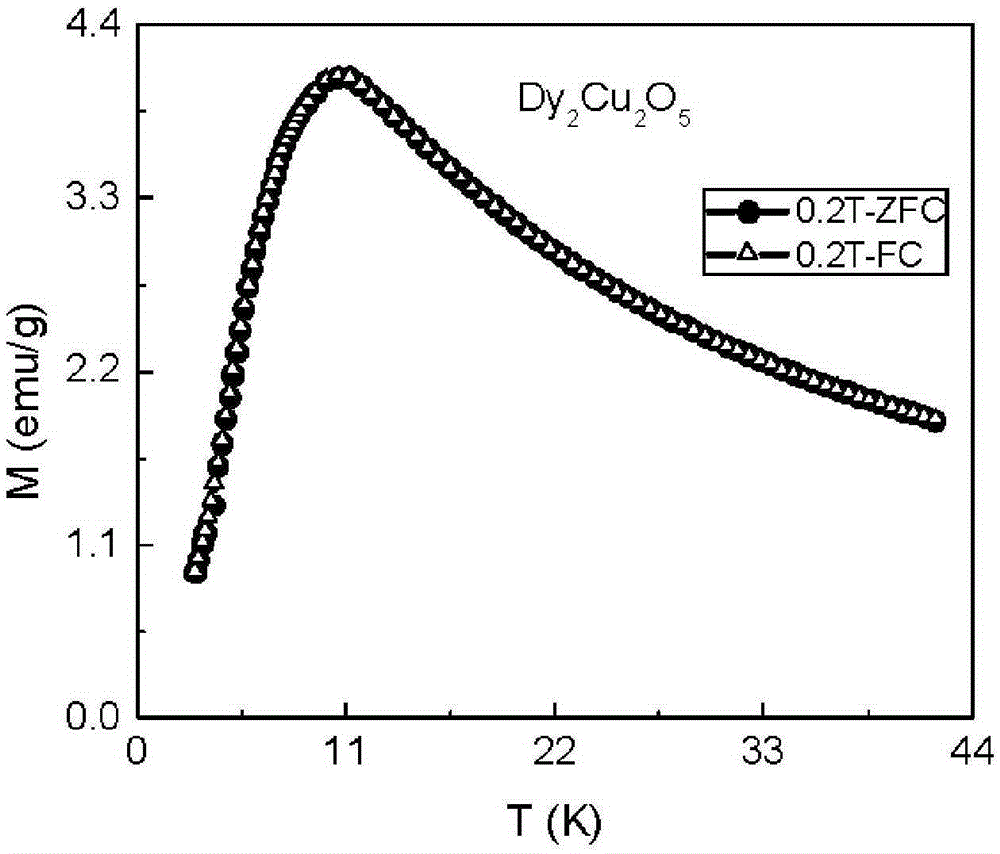

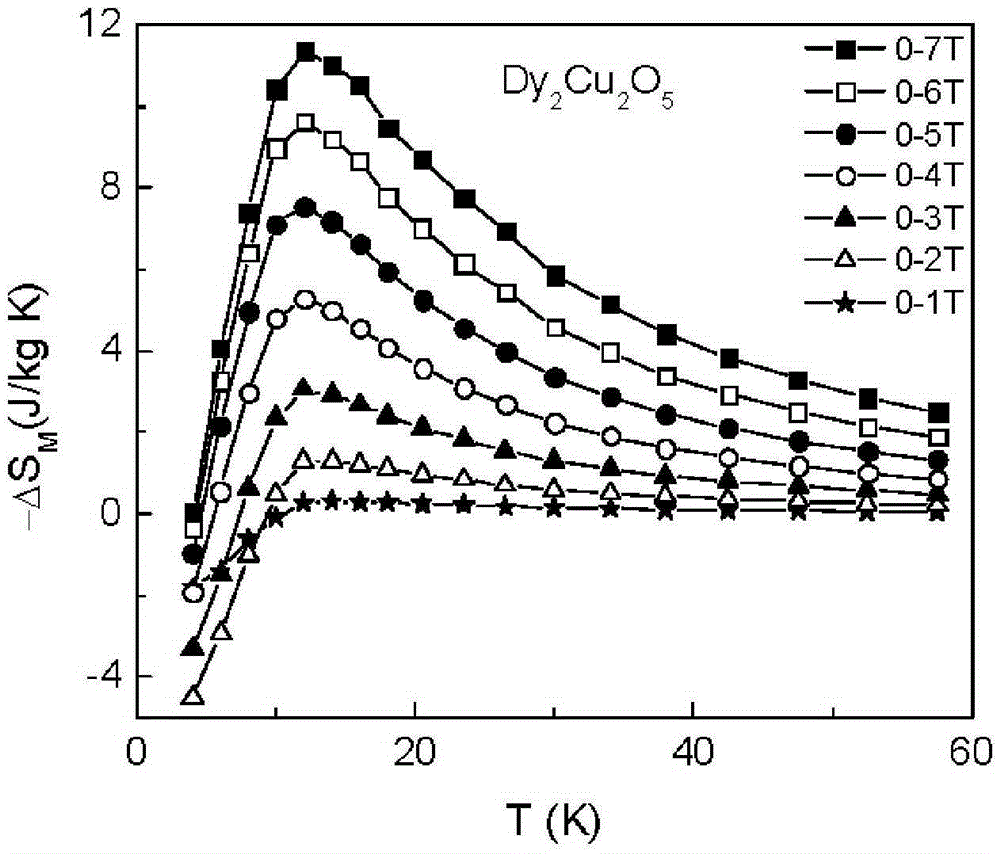

[0024] A Dy used in low temperature magnetic refrigeration 2 Cu 2 o 5 oxide material, the Dy 2 Cu 2 o 5 The oxide material has an orthorhombic crystal structure and belongs to the Pnma space group.

[0025] Dy used in low temperature magnetic refrigeration 2 Cu 2 o 5 The preparation method of oxide material, concrete steps are:

[0026] Step 1: Add 0.02mol of dysprosium oxide and 0.04mol of copper nitrate into dilute nitric acid with a concentration of 3mol / L and keep stirring until the holmium oxide is completely dissolved to form a sol;

[0027] Step 2: Add citric acid dissolved in ethanol, mass of dysprosium oxide: mass of citric acid = 1:2, stir quickly and fully, heat to 90°C and evaporate the water to form a gel;

[0028] Step 3: After cooling, anneal the gel at 520°C for 8 hours to form a sintered product;

[0029] Step 4: Grind the sintered product into powder, press it into a tablet with a tablet press, put it into a corundum crucible, sinter at 880°C for 80...

Embodiment 2

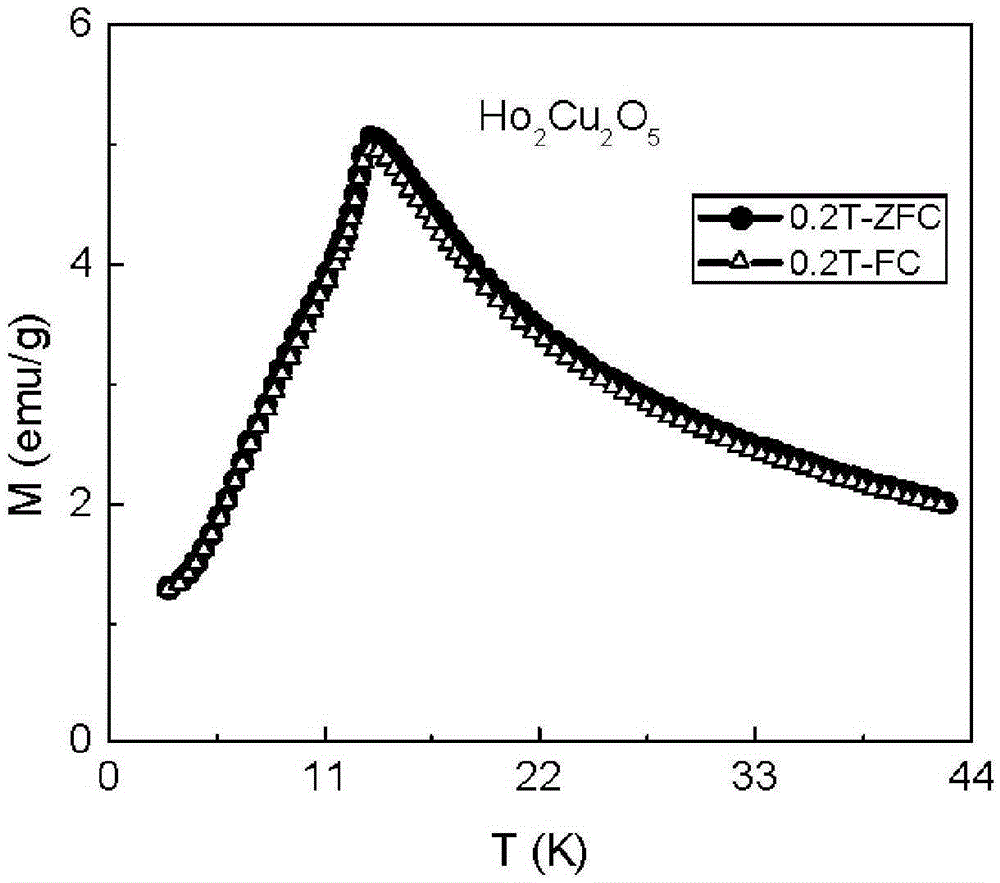

[0035] A kind of Ho used in low temperature magnetic refrigeration 2 Cu 2 o 5 oxide material, the Ho 2 Cu 2 o 5 The oxide material has an orthorhombic crystal structure and belongs to the Pnma space group.

[0036] Ho used in low temperature magnetic refrigeration 2 Cu 2 o 5 The preparation method of oxide material, concrete steps are:

[0037] Step 1: Add 0.02mol of holmium oxide and 0.04mol of copper nitrate into dilute nitric acid with a concentration of 4mol / L and keep stirring until the holmium oxide is completely dissolved to form a sol;

[0038] Step 2: Add citric acid dissolved in ethanol, mass of holmium oxide: mass of citric acid = 1:3, stir quickly and fully, heat to 120°C, evaporate water to dryness, and form a gel;

[0039] Step 3: After cooling, anneal the gel at 480°C for 10 hours to form a sintered product;

[0040] Step 4: Grind the sintered product into powder, press it into a tablet with a tablet machine, put it into a corundum crucible, sinter it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Isothermal magnetic entropy change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com