Purifying method of corn starch 3-grade particles

A corn starch and purification method technology, applied in the field of purification of corn starch granules of different sizes, can solve the problems of insufficient starch, consume a lot of time, and the separation liquid is expensive, so as to overcome the high price, low purification cost and good purification effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

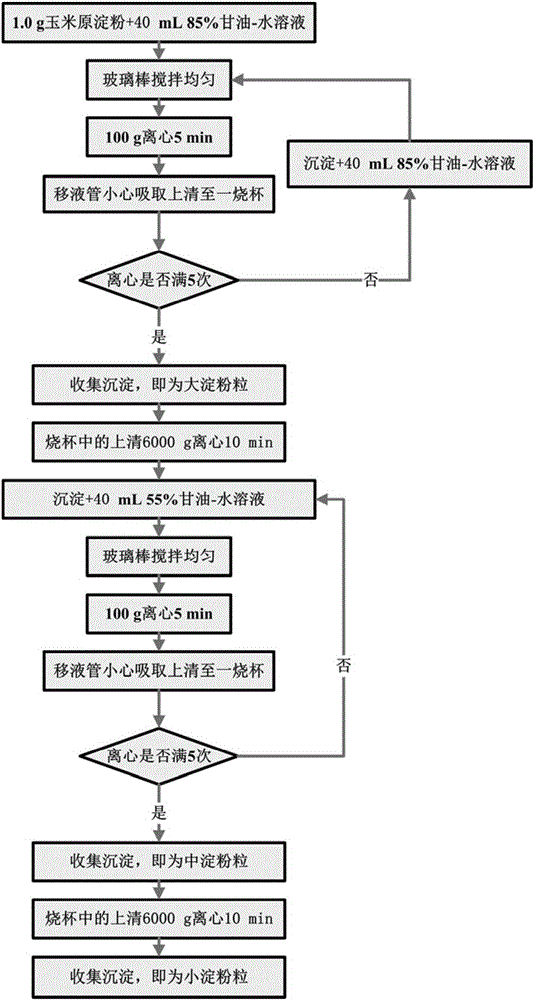

[0067] Embodiment 1: the purification of common corn starch granule: (the flow process of whole purification sees figure 1 )

[0068] (1) Prepare starch suspension:

[0069] ① Prepare 85% glycerin-water solution: 212.5mL pure glycerin + 37.5mL distilled water, mix well;

[0070] ②Weigh 1.0g of ordinary corn starch (purchased from Penford Company) into six 50mL plastic round-bottomed centrifuge tubes (group A centrifuge tubes), add 40mL85% glycerol-water solution to each of the six centrifuge tubes, and make the concentration 2.5% starch suspension;

[0071] (2) Stir evenly: use a glass rod to gently stir the starch suspension in the centrifuge tube for 5 minutes, so that the starch particles are evenly dispersed in the glycerol-water solution;

[0072] (3) 85% glycerol-water solution centrifugation:

[0073] ① Centrifugation: 6 centrifuge tubes were centrifuged immediately at 100g for 5 minutes, and the supernatant was carefully drawn into a beaker with a pipette for purif...

Embodiment 2

[0100] Embodiment 2: the purification of high amylose corn starch granules: (see the flow process of whole purification figure 1 )

[0101] (1) Prepare starch suspension:

[0102] ① Prepare 85% glycerin-water solution: 212.5mL pure glycerin + 37.5mL distilled water, mix well;

[0103] ② Weigh 1.0 g of high-amylose corn starch (purchased from Penford, Australia, number: Gelose50) into six 50 mL plastic round-bottomed centrifuge tubes (group A centrifuge tubes), and add 40 mL of 85% glycerol to each of the six centrifuge tubes- Aqueous solution, made into a starch suspension with a concentration of 2.5%;

[0104] (2) Stir evenly: use a glass rod to gently stir the starch suspension in the centrifuge tube for 5 minutes, so that the starch particles are evenly dispersed in the glycerol-water solution;

[0105] (3) 85% glycerol-water solution centrifugation:

[0106] ① Centrifugation: 6 centrifuge tubes were centrifuged immediately at 100g for 5 minutes, and the supernatant was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com