A method for increasing epa and dha content in glyceride type fish oil

A technology for glyceride-type and ethyl-ester-type fish oil, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of large amount of commercial lipase, limited industrial production, and high production cost, and achieves strong production efficiency. Transesterification activity, low production cost, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

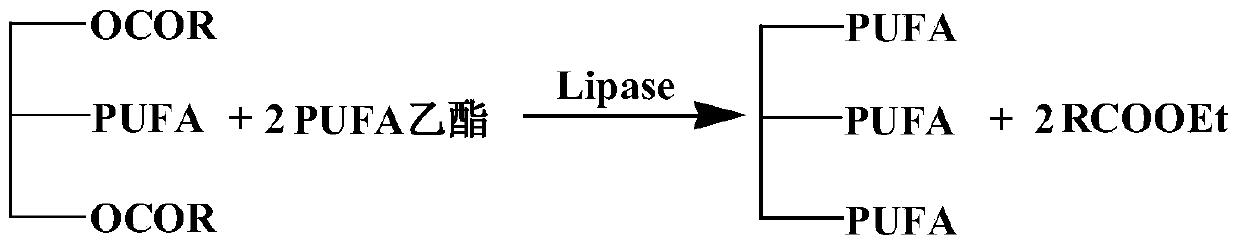

Method used

Image

Examples

Embodiment 1

[0020] Slant cultivation: Aspergillus oryzae WZ007 (preservation number CCTCC No. M 206105) was inoculated into the slant medium and cultured at 30° C. for 3 days to serve as slant activation seeds. Final concentration composition of slant medium quality: NaNO 3 0.2%, K 2 HPO 4 0.1%, KCl 0.5%, FeSO 4 0.001%, MgSO 4 0.05%, 3% sucrose, 1.5% agar, deionized water as solvent, natural pH, sterilized at 121°C for 20 minutes.

[0021] Fermentation culture: inoculate slant seeds into 1L liquid fermentation medium, culture at 30°C and 200r / min for 48 hours, filter the culture solution, and obtain 80g wet weight of mycelia. The final concentration of the liquid fermentation medium consists of: glucose 20g / L, peptone 20g / L, sucrose 10g / L, urea 3g / L, NaCl 5g / L, K 2 HPO 4 2g / L, MgSO 4 1g / L, (NH 4 ) 2 SO 45g / L, the solvent is deionized water, the pH is natural, the liquid volume is 80ml in a 500ml Erlenmeyer bottle, and it is sterilized at 121°C for 20 minutes.

[0022] 80 g...

Embodiment 2

[0023] Embodiment 2: the preparation of ethyl ester type fish oil

[0024] Preparation of ethyl ester type fish oil (EPA and DHA total content 60-70%, EPA mass content 35-40%, DHA mass content 25-30%):

[0025] Sardine fish oil (21% EPA mass content, 9% DHA mass content) was enriched by molecular distillation and urea embedding method. Using 21% EPA mass content and 9% DHA mass content sardine fish oil as raw material, carry out molecular distillation in POPE 2inch WFS molecular distillation apparatus (POPE Science Company, USA). Add urea for urea embedding, and prepare ethyl ester type fish oil with 38% EPA mass content and 28% DHA mass content, wherein molecular distillation conditions: distillation temperature 90°C, preheating temperature 40°C, internal cooling temperature 15°C, scraping film The concentration of ethylated fish oil was carried out under the conditions of 360r / min rotating speed, 2mL / min feeding rate and 0.1Pa vacuum degree. Urea embedding conditions: mass...

Embodiment 3

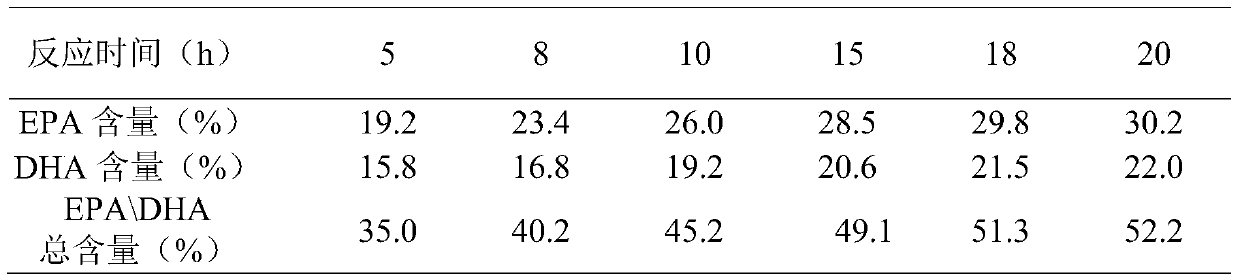

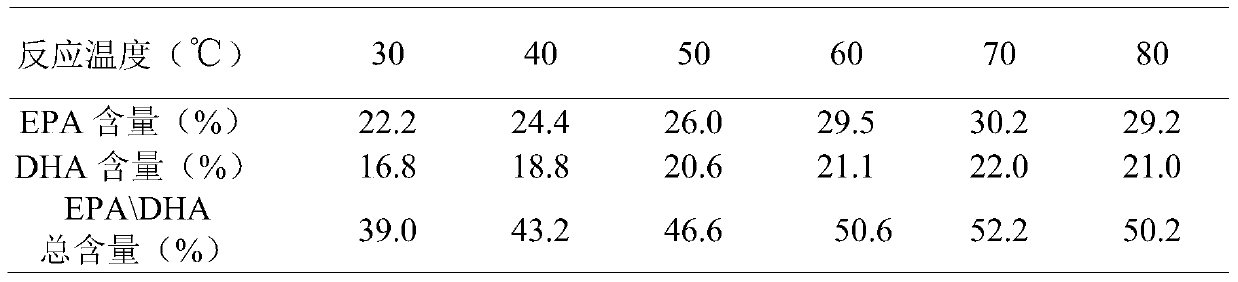

[0027] 1g of Aspergillus oryzae WZ007 freeze-dried thalline prepared by the method of Example 1, anchovy fish oil (11% of EPA mass content, 14% of DHA mass content) and ethyl ester type fish oil (prepared by the method of Example 2, EPA mass content of 38%) , DHA mass content 28%) each 5ml (glyceride and ethyl ester molar ratio 1:3), under 70 ℃, 200rpm condition, after water bath reaction 20h, monitor the total content of EPA and DHA in the ethyl ester type fish oil by gas chromatography Change, when the total content of EPA and DHA is stable, end the reaction, filter the reaction solution, collect the dry cells, distill the filtrate under reduced pressure until no liquid flows out (50Pa, 240°C) to remove EPA\DHA ethyl ester, and obtain the concentrated The product is a high-content EPA and DHA glyceride type fish oil, and the total content of EPA and DHA is 50.2% after testing, of which EPA content is 29.2%, and DHA content is 21.0%.

[0028] Detection method of EPA and DHA c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com