Preparation method of lithium ion battery negative electrode spherical WO3 material with micro-nano hierarchical structure

A lithium-ion battery and hierarchical structure technology, which is applied to battery electrodes, secondary batteries, structural parts, etc., can solve the problems of low charge-discharge specific capacity and poor cycle performance stability, and achieve simple synthesis methods, uniform appearance, and easy The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

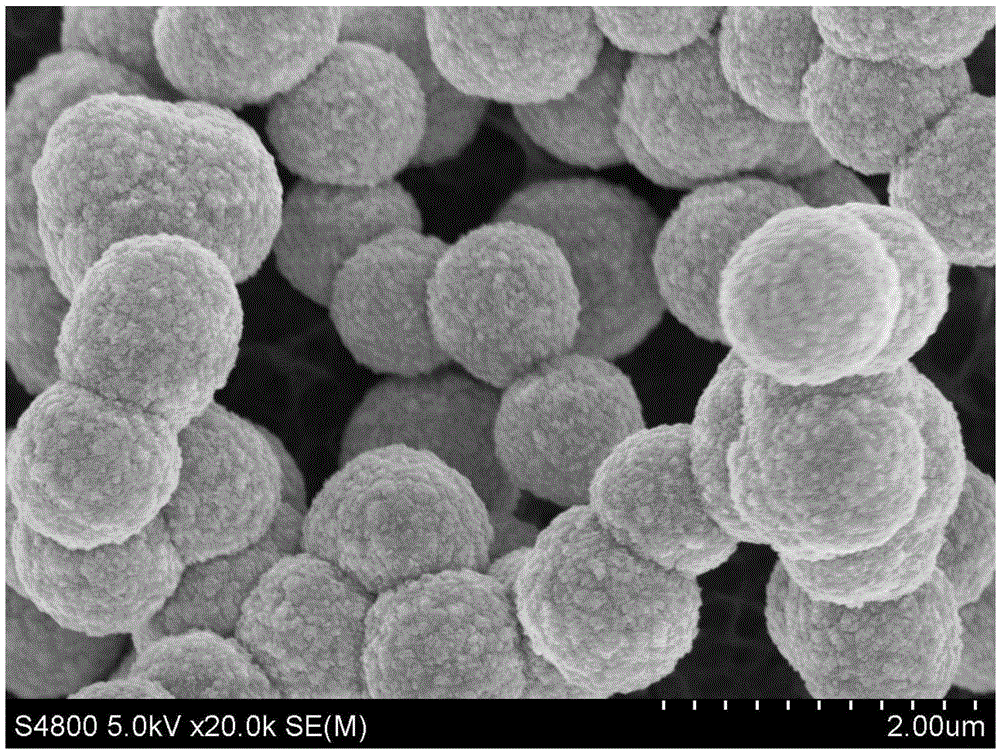

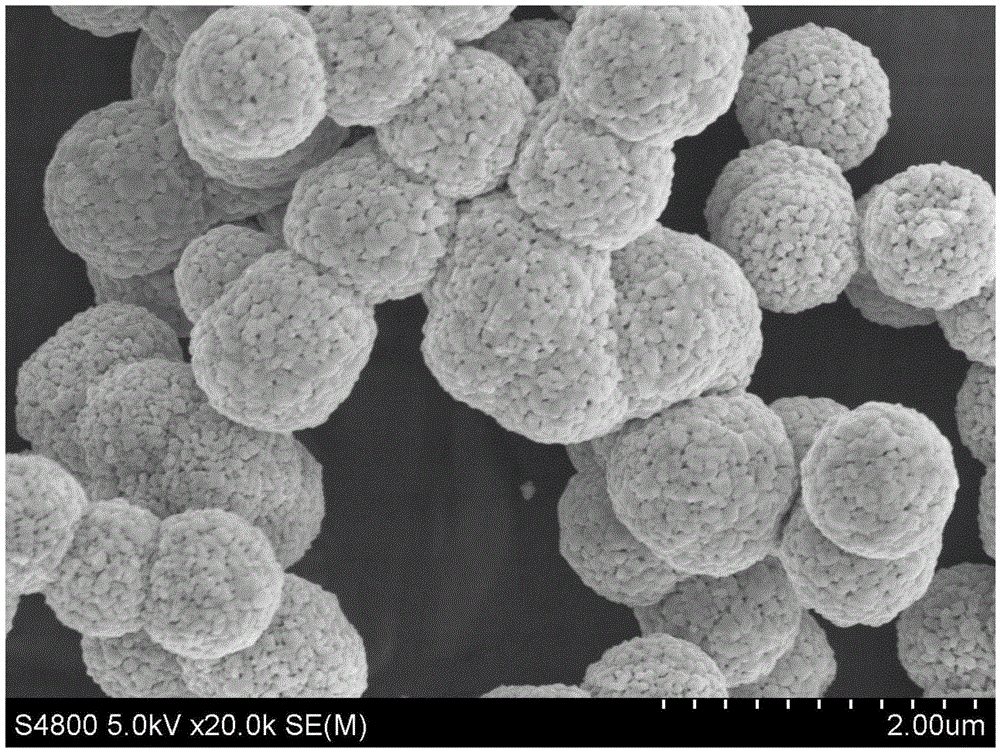

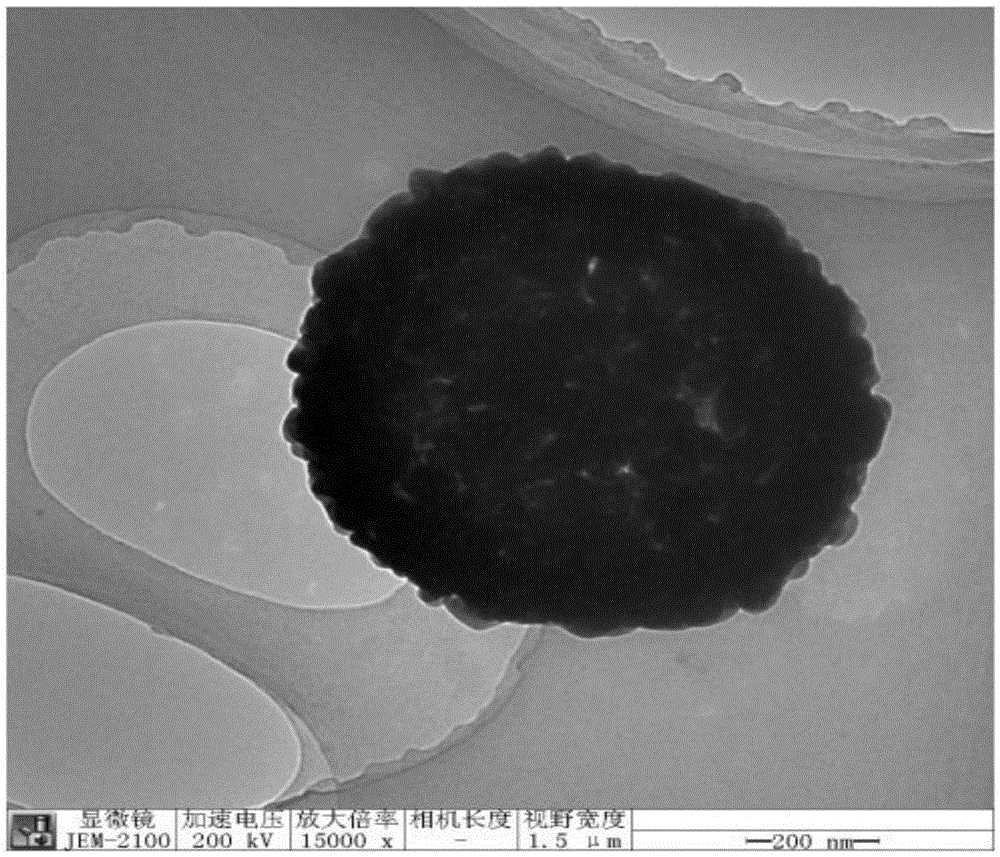

[0012] Specific implementation mode 1: In this implementation mode, a lithium-ion battery negative electrode spherical WO with a micro-nano hierarchical structure 3 The preparation method of the material is as follows: 1. Mix tungsten hexachloride and solvent, stir it magnetically for 20-60 minutes, and prepare a mixed solution with a concentration of 0.01-0.1mol / L; 2. Adjust the pH value of the mixed solution between 2-6 3. Transfer the mixed solution to the reaction kettle, react at a temperature of 120-250°C for 2-48 hours, then wash with anhydrous methanol, and dry in vacuum to obtain a tungsten oxide precursor; 4. Put the tungsten oxide precursor Sintering at 400-800°C for 1-8 hours in an air atmosphere to obtain a lithium-ion battery negative electrode spherical WO with a micro-nano hierarchical structure 3 Material.

[0013] The synthesis method of this embodiment is simple, controllable and easy for large-scale production. The synthesized product is pure phase WO 3 ...

specific Embodiment approach 2

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the solvent in step 1 is methanol, isopropanol or acetic acid. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 1, a mixed solution with a concentration of 0.0286 mol / L is prepared. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com