A new process for preparing vinylalkoxysilane

A technology of vinyl alkoxysilane and alkoxysilane, which is applied in the field of new synthetic technology of vinyl alkoxysilane, can solve the problems of poor economy, high price, and increased processing difficulty of waste acid, so as to improve the addition Effect on Response Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

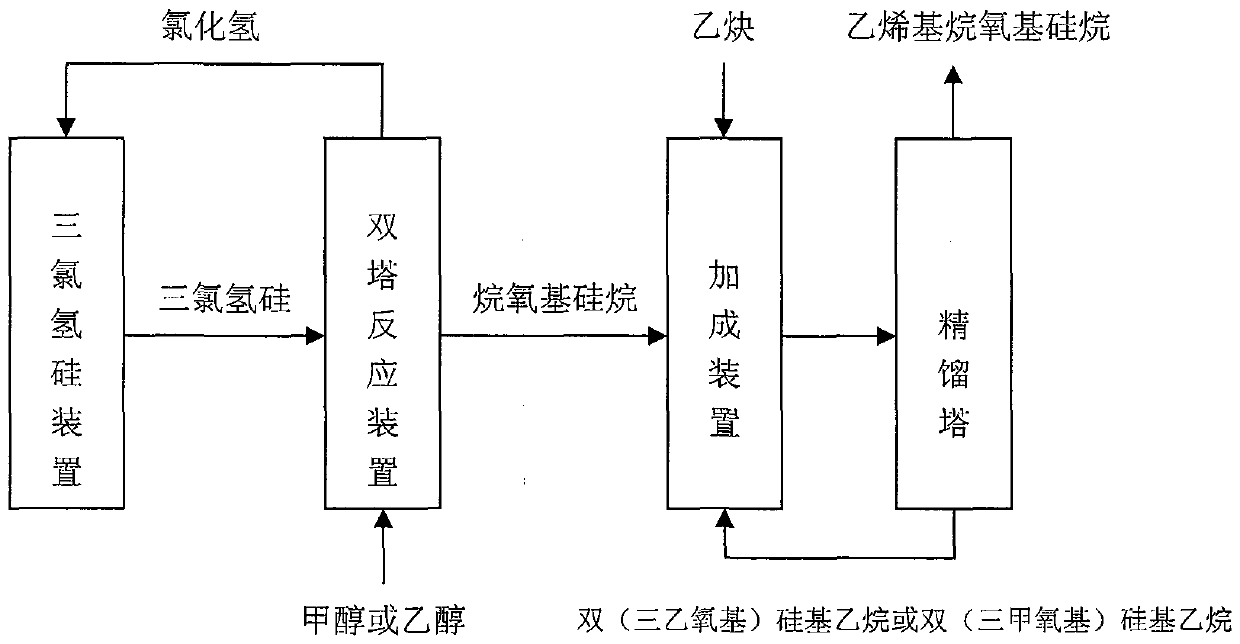

Method used

Image

Examples

Embodiment 1

[0031] Put the solvent bis(triethoxy)silylethane into the reaction kettle, add the catalyst, raise the temperature to 70°C, then put the triethoxysilane into the addition kettle and open the acetylene inlet valve to start the reaction. The reactor pressure was 30kpa, and when the reactor pressure began to slowly rise to 50kpa, the reaction was stopped. The feed liquid is poured into a rectification tower for rectification, vinyltriethoxysilane is extracted from the top of the tower, and bis(triethoxy)silylethane, a by-product at the bottom of the tower, is recovered and used as a reaction solvent. The product yield of vinyltriethoxysilane is 92.9%, and the purity is more than 99%.

Embodiment 2

[0033] The trichlorosilane and methanol obtained by the reaction of hydrogen chloride and silicon powder at 230°C to 260°C are pumped into the double-tower reactor respectively with a metering pump, the temperature is raised to 40°C, and the reaction circulation pump is turned on. The hydrogen chloride produced in the process passes through the cryogenic , and return to the trichlorosilane synthesis device after compression. After reacting for 6 hours, the solution was neutralized and rectified to obtain trimethoxysilane with a yield of 81%. Put the solvent bis(trimethoxy)silylethane into the reaction kettle, add the catalyst, raise the temperature to 70°C, then put the trimethoxysilane into the addition kettle and open the acetylene inlet valve to start the reaction. The reactor pressure was 30kpa, and when the reactor pressure began to slowly rise to 50kpa, the reaction was stopped. The feed liquid is poured into a rectification tower for rectification, vinyltrimethoxysilan...

Embodiment 3

[0035] The trichlorosilane and ethanol obtained by the reaction of hydrogen chloride and silicon powder at 230°C to 260°C are pumped into the double-tower reactor respectively with a metering pump, the temperature is raised to 80°C, and the reaction circulation pump is turned on. The hydrogen chloride produced in the process passes through the cryogenic , and return to the trichlorosilane synthesis device after compression. After reacting for 6 hours, the solution was neutralized and rectified to obtain triethoxysilane with a yield of 86%. Put the solvent bis(triethoxy)silylethane into the reaction kettle, add the catalyst, raise the temperature to 85°C, then put the triethoxysilane into the addition kettle and open the acetylene inlet valve to start the reaction. The reactor pressure was 30kpa, and when the reactor pressure began to slowly rise to 50kpa, the reaction was stopped. The feed liquid is poured into a rectification tower for rectification, vinyltriethoxysilane is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com