Nano microemulsion, and preparation method and application thereof

A nano-micro-emulsion and micro-emulsion technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of expansion and collapse of the well wall and the limitation of high temperature resistance of filtrate reducers, so as to prevent the collapse of the well wall. , Improve suspension stability and rock-carrying ability, good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Modification of silicate

[0040] In a constant temperature water bath at 30°C, 50 parts by weight of kaolin with a particle size of 2.5 μm was added to 1.5 L of deionized water, controlled at a rotational speed of 500 r / min, and stirred evenly.

[0041] Nitrogen is fed into the system, and at 70°C, 45 parts by weight of the modifier aqueous solution is dropped into 40 parts by weight of the silicate solution, and the dropping rate of the modifier aqueous solution is controlled to be 10ml / min, and the manufacturing speed is 500r / min. After 16 h, the reaction was stopped. The reaction solution was filtered, and the filter cake was rinsed with water until the filtrate was washed with 0.1mol / LAgNO 3 After the solution detected no white precipitate, the filter cake was dried in a vacuum oven at 90° C. for 15 hours until constant weight, ground, and set aside. Wherein, the modifier aqueous solution includes cetyltrimethylammonium bromide, dioctadecyldimethylammonium bro...

Embodiment 2

[0052] 1. Modification of silicate

[0053] In a constant temperature water bath at 40°C, add 60 parts by weight of a mixture of montmorillonite and hydrotalcite with a particle size of 0.9 μm into 1.5 L of deionized water, control the rotation speed at 200 r / min, and stir evenly.

[0054] Nitrogen is fed into the system, and at 60°C, 60 parts by weight of the modifier aqueous solution is dropped into 60 parts by weight of the silicate solution, and the dropping rate of the modifier aqueous solution is controlled to be 8ml / min, and the manufacturing speed is 800r / min. After 16 h, the reaction was stopped. The reaction solution was filtered, and the filter cake was rinsed with water until the filtrate was washed with 0.1mol / LAgNO 3 After the solution detected no white precipitate, the filter cake was dried in a vacuum oven at 60° C. for 20 h until constant weight, ground, and set aside. Wherein, the modifier aqueous solution includes cetyltrimethylammonium bromide, dioctadecy...

Embodiment 3

[0063] 1. Modification of silicate

[0064] In a constant temperature water bath at 40°C, 60 parts by weight of layered silica with a particle size of 3.0 μm was added to 1.0 L of deionized water, controlled at a rotational speed of 400 r / min, and stirred evenly.

[0065] Nitrogen is fed into the system, and at 50°C, 20 parts by weight of the modifier aqueous solution is dropped into 50 parts by weight of the silicate solution, and the dropping rate of the modifier aqueous solution is controlled to be 12ml / min, and the rotational speed is controlled to be 800r / min. After 18 h, the reaction was stopped. The reaction solution was filtered, and the filter cake was rinsed with water until the filtrate was washed with 0.1mol / LAgNO 3 After the solution detected no white precipitate, the filter cake was dried in a vacuum oven at 70° C. for 30 h until constant weight, ground and set aside. Wherein, the modifier aqueous solution includes cetyl trimethyl ammonium bromide, tetradecyl t...

PUM

| Property | Measurement | Unit |

|---|---|---|

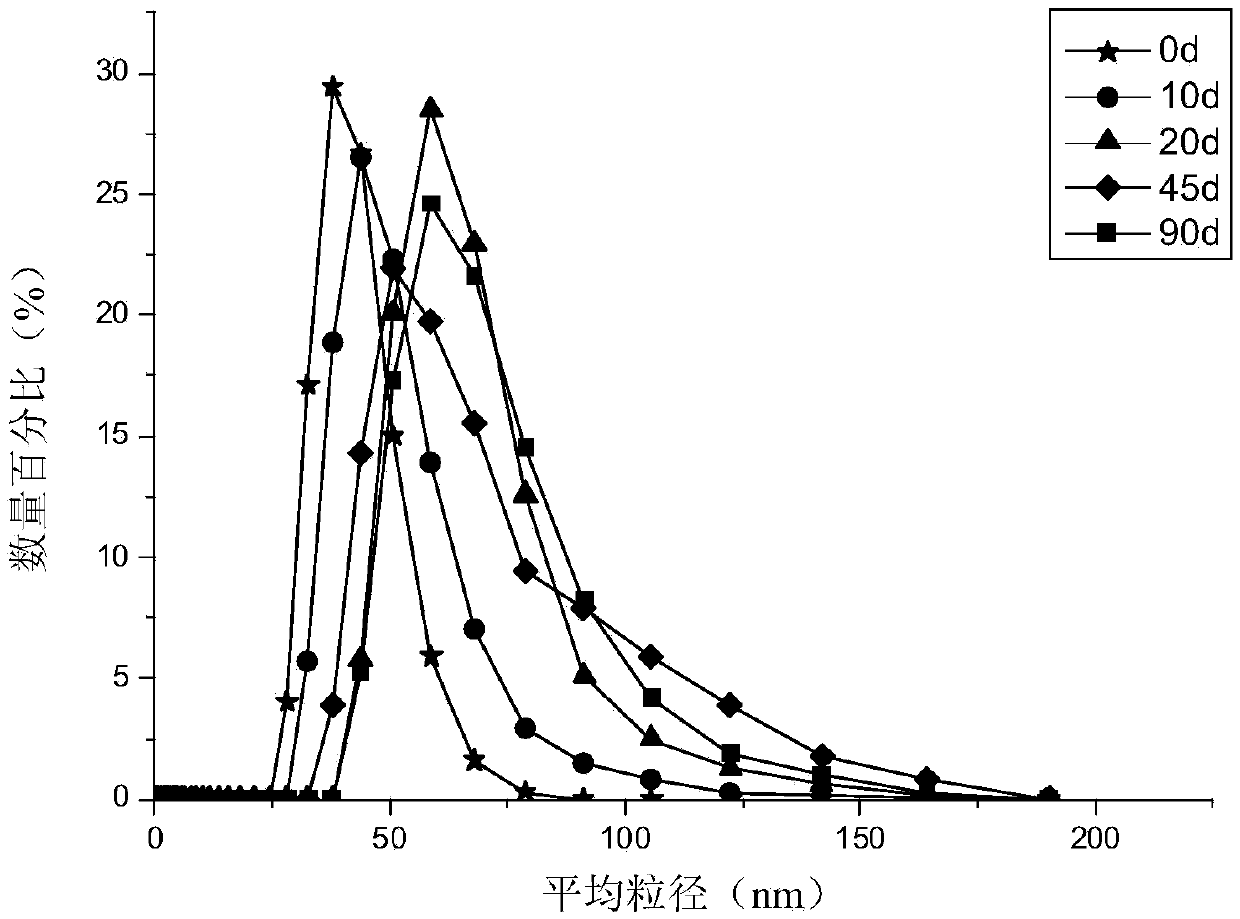

| particle diameter | aaaaa | aaaaa |

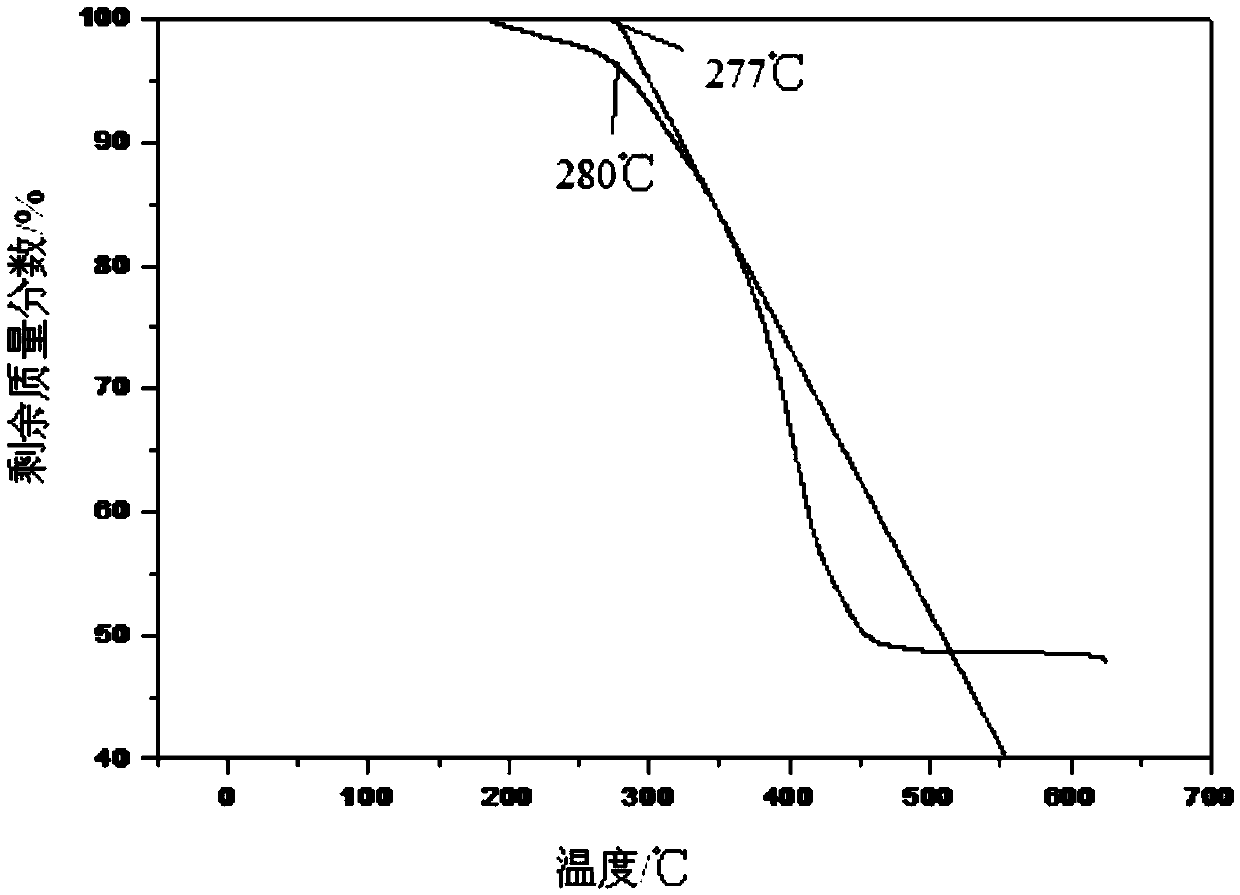

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com