A kind of method utilizing pet to synthesize unsaturated polyester resin

A polyester resin, unsaturated technology, applied in the field of polymer chemistry, can solve the problems of expensive, product scrapping, product quality, decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

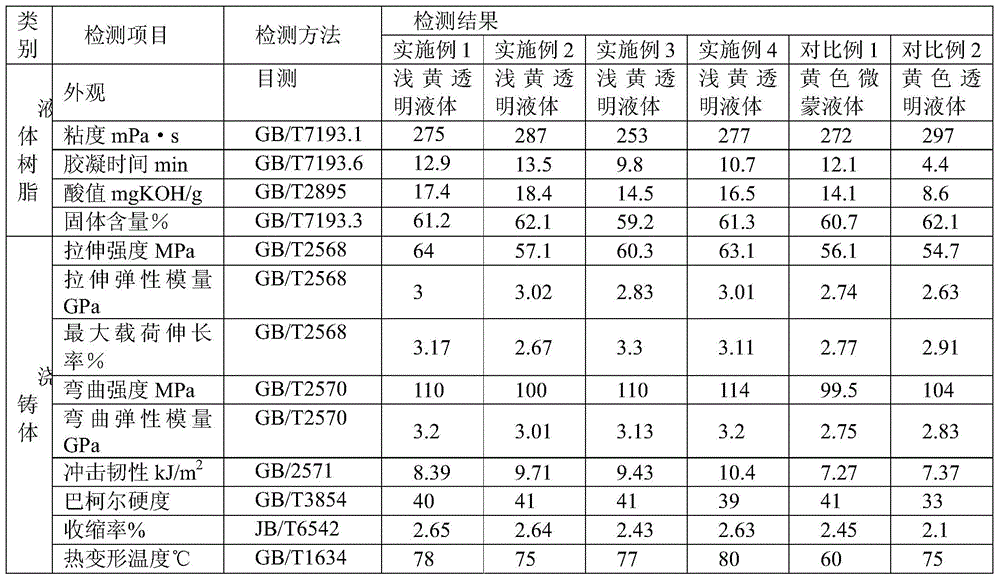

Examples

Embodiment 1

[0028] In a 2L four-necked flask with a thermometer, a mechanical stirrer, a nitrogen introduction tube and a reflux condenser, 97g of glycerol (industrial grade, 95% wt. purity), 272g of diethylene glycol, 384g of waste PET and 1g of Zinc acetate, turn on the mechanical stirring, stir at a speed of 260 r / min, and quickly heat up to 210 °C under nitrogen protection for thermal insulation reaction. The temperature was lowered to below 150°C, 461g maleic anhydride, 130g isooctanol and 76g propylene glycol were added, the temperature was raised to 150°C for 0.5h, and then the temperature was gradually raised to 195°C for constant temperature reaction. Pay attention to controlling the temperature of the distillation head until the acid value When it reaches 55mgKOH / g, when the water output reaches 85-90% of the theoretical amount, the water is forced to be discharged by vacuuming, and the reaction is carried out until the acid value is lower than 25mgKOH / g. Cool to 155°C, add 0.3g...

Embodiment 2

[0030] In a 2L four-necked flask with a thermometer, a mechanical stirrer, a nitrogen introduction tube and a reflux condenser, 58g of glycerol (industrial grade, 95% wt. purity), 380g of diethylene glycol, 384g of waste PET and 1g of Zinc acetate, turn on the mechanical stirring, stir at a speed of 250 r / min, and quickly heat up to 210 ° C under nitrogen protection for thermal insulation reaction. The temperature was lowered to below 150°C, 451g maleic anhydride, 78g isooctanol and 46g propylene glycol were added, the temperature was raised to 155°C for 0.5h, and then the temperature was gradually raised to 200°C for constant temperature reaction. Pay attention to controlling the temperature of the distillation head until the acid value When it reaches 55mgKOH / g, when the water output reaches 85-90% of the theoretical amount, the water is forced to be discharged by vacuuming, and the reaction is carried out until the acid value is lower than 25mgKOH / g. Cool to 160°C, add 0.3g...

Embodiment 3

[0032]In a 2L four-necked flask with a thermometer, a mechanical stirrer, a nitrogen introduction tube and a reflux condenser, 105g of glycerol (industrial grade, purity of 95% wt.), 370g of diethylene glycol, 346g of waste PET and 0.9 g zinc acetate, turn on the mechanical stirring, stir at a speed of 280 r / min, and quickly heat up to 210 °C under nitrogen protection for thermal insulation reaction. The temperature was lowered to below 150°C, 459g maleic anhydride and 140g isooctanol were added, the temperature was raised to 152°C for 0.5h, and then the temperature was gradually raised to 195°C for constant temperature reaction. Pay attention to controlling the temperature of the distillation head until the acid value reached 55mgKOH / g, when the water output reaches 85-90% of the theoretical amount, the water is forced to be discharged by vacuuming, so that the reaction proceeds until the acid value is lower than 25mgKOH / g. Cool to 156°C, add 0.3g o-methyl hydroquinone, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com