Method for multi-tower parallel connected adsorption removal of polycyclic aromatic hydrocarbons in diesel oil

A technology for polycyclic aromatic hydrocarbons and diesel oil, applied in the petroleum industry, treating hydrocarbon oil, refining hydrocarbon oil, etc., can solve the problems of high operating cost, harsh conditions, and less research on adsorption and separation applications, and achieve low operating cost and low energy consumption , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

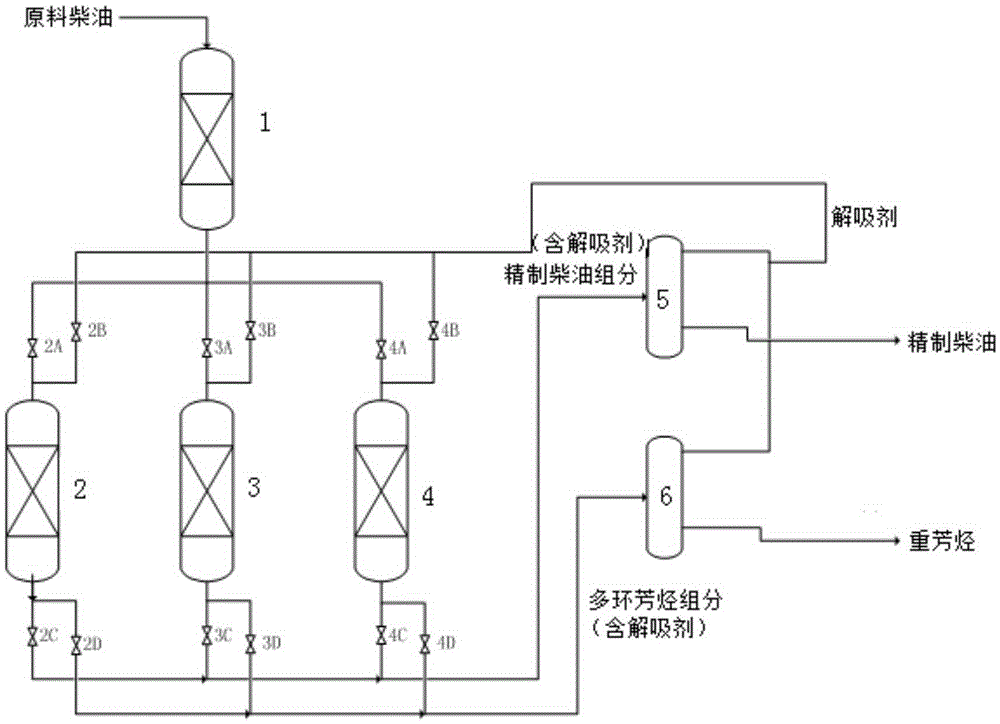

Method used

Image

Examples

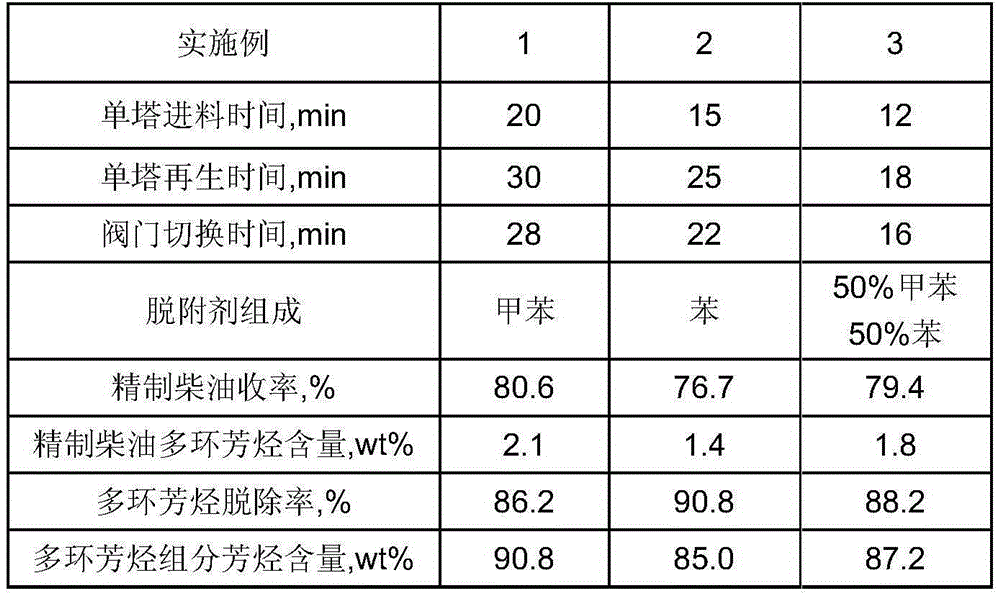

Embodiment 1

[0038] (1) The diesel pretreatment adsorbent adopts silicon oxide adsorbent, SiO 2The content is 99.9%, the average pore size of the adsorbent is 4-15nm, and the specific surface area is 280-450cm 2 / g, the pore volume is 0.5~0.9ml / g; the polycyclic aromatic hydrocarbon adsorbent adopts the composite adsorbent of alumina and silica, SiO 2 The content is 66%, Al 2 o 3 The content is 33%, and the rest are impurities.

[0039] (2) Pretreatment process conditions: diesel oil is passed into the pretreatment adsorption tower at 50ml / min, the temperature of the adsorbent bed in the pretreatment tower is controlled at 40-60°C, the pressure is 0.6-0.7MPa, and the adsorption space velocity is 0.8-1.0h -1 .

[0040] (3) The multi-tower parallel adsorption device includes 3 adsorption towers, each tower is filled with 2700ml of adsorbent, and the adsorption tower is first wetted with desorbent.

[0041] (4) The pretreated diesel oil enters the adsorption tower 2 through the valve 2A,...

Embodiment 2

[0044] (1) The diesel pretreatment adsorbent adopts silicon oxide adsorbent, SiO 2 The content is 99.9%, the average pore size of the adsorbent is 4-15nm, and the specific surface area is 280-450cm 2 / g, the pore volume is 0.5~0.9ml / g; the polycyclic aromatic hydrocarbon adsorbent adopts the composite adsorbent of alumina and silica, SiO 2 Content is 50%, Al 2 o 3 The content is 49%, and the rest are impurities.

[0045] (2) Pretreatment process conditions: diesel oil is passed into the pretreatment adsorption tower at 50ml / min, the temperature of the adsorbent bed in the pretreatment tower is controlled at 40-60°C, the pressure is 0.6-0.8MPa, and the adsorption space velocity is 1.0-1.2h -1 .

[0046] (3) The multi-tower parallel adsorption device includes 3 adsorption towers, each tower is filled with 2700ml of adsorbent, and the adsorption tower is first wetted with desorbent.

[0047] (4) The pretreated diesel oil enters the 2# adsorption tower through valve 2A, and t...

Embodiment 3

[0050] (1) The diesel pretreatment adsorbent adopts silicon oxide adsorbent, SiO 2 The content is 99.9%, the average pore size of the adsorbent is 4-15nm, and the specific surface area is 280-450cm 2 / g, the pore volume is 0.5~0.9ml / g; the polycyclic aromatic hydrocarbon adsorbent adopts the composite adsorbent of alumina and silica, SiO 2 Content is 40%, Al 2 o 3 The content is 59%, and the rest are impurities.

[0051] (2) Pretreatment process conditions: diesel oil is passed into the pretreatment adsorption tower at 50ml / min, the temperature of the adsorbent bed in the pretreatment tower is controlled at 40-60°C, the pressure is 0.6-0.8MPa, and the adsorption space velocity is 1.0-1.2h -1 .

[0052] (3) The multi-tower parallel adsorption device includes 3 adsorption towers, each tower is filled with 2700ml of adsorbent, and the adsorption tower is first wetted with desorbent.

[0053] (4) The pretreated diesel oil enters the 2# adsorption tower through valve 2A, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com