Biomass material microwave-assisted pyrolysis gasification device, and application method thereof

A biomass material, microwave-assisted technology, applied in gasification process, fixed bed gasification, chemical industry, etc., can solve the problems of low quality of synthesis gas utilization, high operating cost, inability to heat biomass raw materials, etc., and achieve high efficiency and cleanliness The effect of energy conversion, accelerating gasification reaction rate, and ensuring heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

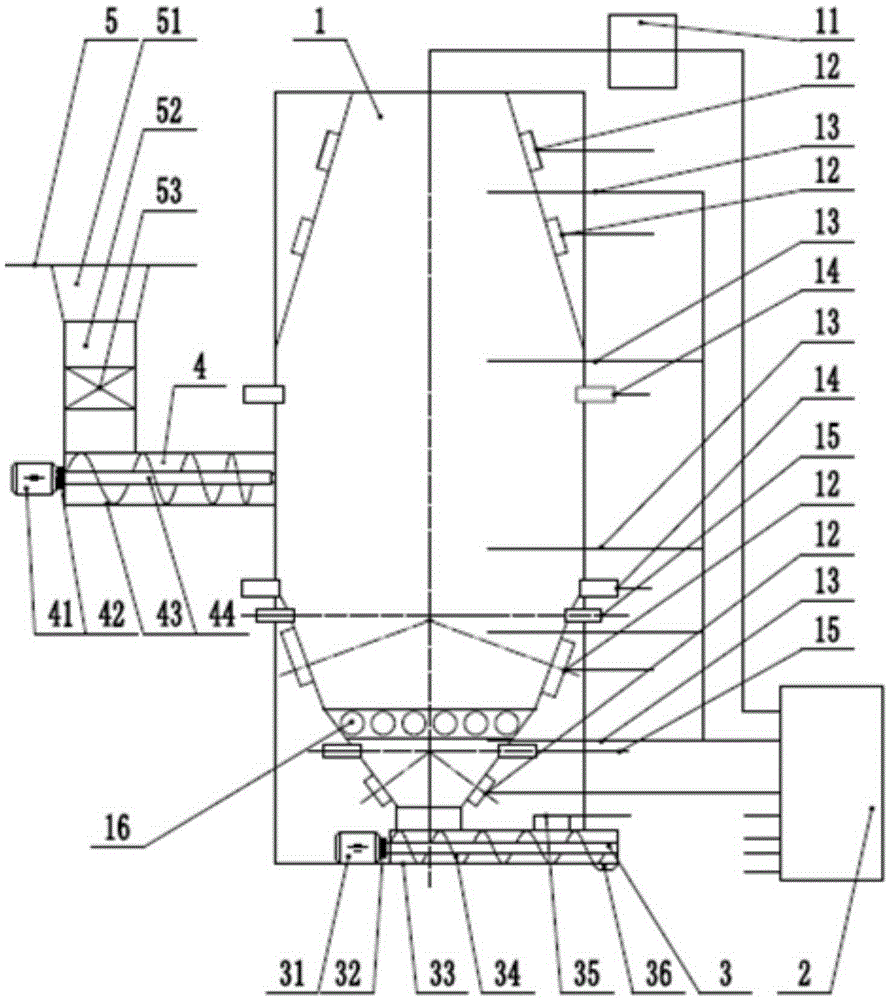

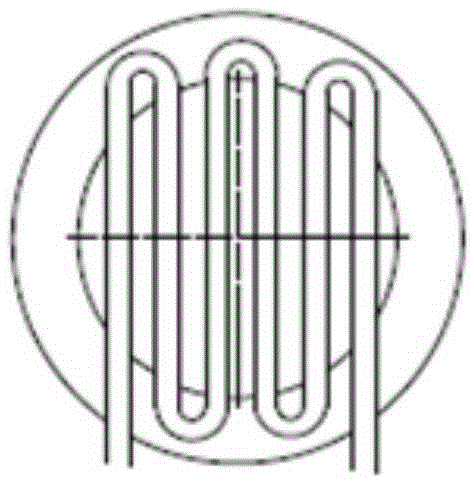

[0033] The gas making device comprises a microwave gasifier 1, and the microwave gasifier 1 comprises a shell, and an outer shell and an insulating layer covering the shell are provided outside the shell; in order to ensure the concentration of energy and the reaction temperature in the furnace, Both the upper and lower ends of the housing are conical, and microwave generators 12 are provided on the upper and lower conical housings of the housing. The lower end of the housing is provided with an ash discharge conveying device 3, and one side of the housing is provided with a feed port for biomass materials. The housing is provided with several steam inlets 14 and several gas inlets 15. There are heat exchange tubes 16, and the heat exchange tubes 16 are arranged horizontally, which are heat exchange coils, such as figure 2 shown.

[0034] Preferably, the operating frequency of the microwave generator is 2450±50 MHz, and the output power is continuously adjustable from 0.3 to...

Embodiment 2

[0041] The difference between this embodiment and embodiment 1 is:

[0042] There are many heat exchange tubes 16, the inlet of the heat exchange tubes 16 is led into normal temperature air, and the outlet of the heat exchange tubes 16 is connected with the gas inlet end of the gasifier body, as figure 1 shown.

Embodiment 3

[0044] The difference between this embodiment and embodiment 1 is:

[0045] The heat exchange tubes 16 are arranged obliquely or vertically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com