Saccharomyces cerevisiae strain for expressing xylose isomerase and construction method

A technology of Saccharomyces cerevisiae strain and xylose isomerase, which is applied in microorganism-based methods, botanical equipment and methods, biochemical equipment and methods, etc., can solve the problems of slow growth rate of recombinant bacteria and inability to meet fermentation requirements, etc., Achieve the effect of fast xylose fermentation and high ethanol yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A strain of Saccharomyces cerevisiae expressing xylose isomerase, the Saccharomyces cerevisiae ( Saccharomycescerevisiae The SEB7) strain is deposited in the China Common Microbial Species Collection and Management Center, and the deposit number is CGMCC11327. The specific construction method of the Saccharomyces cerevisiae strain SEB7 is as follows:

[0027] 1) Construct the starting strain:

[0028] Saccharomyces cerevisiae SEB3 was cultured on a sporulation medium (0.5g / L glucose, 20g / L potassium acetate, 2g / L yeast powder, pH 5.5) for 2 days, and then treated with lysozyme at 30°C for 10-20 minutes. Pick single spores on the four-spore analyzer, and obtain haploid cells after verification. In the present invention, only haploids with sex α are selected, and the haploid strain SEB3α25 is finally screened.

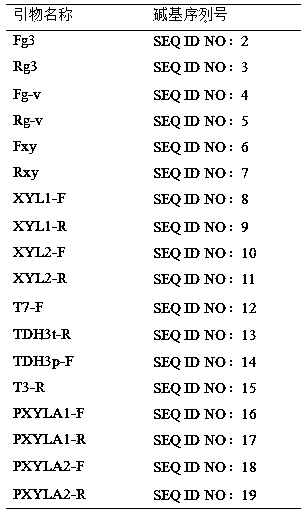

[0029] Using the plasmid pBlu-LTKTL-TDH3 as a template, it was amplified with primers Fg3 / Rg3 loxP-KanMX-loxP The fragments were then introduced into the strain SEB3α...

Embodiment 2

[0057] This example is a comparative example of example 1. The construction steps and construction conditions in this example are the same as those of example 1, except that the primers PXYLA1-F / PXYLA1-R and PXYLA2-F / are used in step 2.4). PXYLA2-R the original gene sequence of xylose isomerase PXYLA1 Amplify it and combine it with plasmid pRS426-P TDH3 -T TDH3 through EcoR After digestion with restriction enzyme I, ligation with T4 ligase, and verification by restriction enzyme digestion and sequencing, the multi-copy expression vector pRS426-PXYLA1 was obtained.

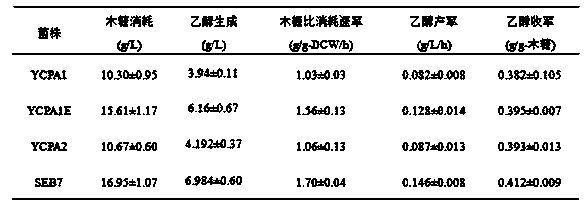

[0058] After step 3) construction, industrial Saccharomyces cerevisiae YCPA1 is obtained. Strain YCPA1E was obtained by performing step 4) aerobic growth acclimation and microaerobic fermentation acclimation on strain YCPA1.

[0059] Through the growth evaluation of YCPA1 and YCPA2, before the 5th generation, the strain needs to be cultured for 36h to reach the mid-log growth phase. In the first five generations ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com