Carbon-copper double-doped sapphire crystal and preparing method thereof

A sapphire crystal and carbon-copper technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve problems such as difficulty in forming multivalent states and meeting requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh C, CuO and Al by x=0.2wt%, y=0.025wt% 2 o 3 Raw material 500g. Combine C and Al 2 o 3 Put it into a molybdenum crucible, put it into a high-temperature firing furnace protected by an inert atmosphere, raise the temperature at 150°C / h to 2050°C, keep it for 2 hours, and then cool it down to room temperature at 200°C / h. Then put CuO into the above-mentioned filled with C and Al 2 o 3 In the crucible of the sintered material, repeat the above-mentioned sintering process. Take out the prepared material from the crucible, place it in a tungsten crucible for crystal growth, and grow C:Cu:Al by temperature gradient method 2 o 3 crystals. A sapphire seed crystal in the direction was put into the bottom of the crucible, and the crystal growth was carried out in an Ar gas environment. The melting rate of the raw material is 100°C / h, the crystallization rate of the melt is 1°C / h, and the cooling rate of the crystal is 30°C / h.

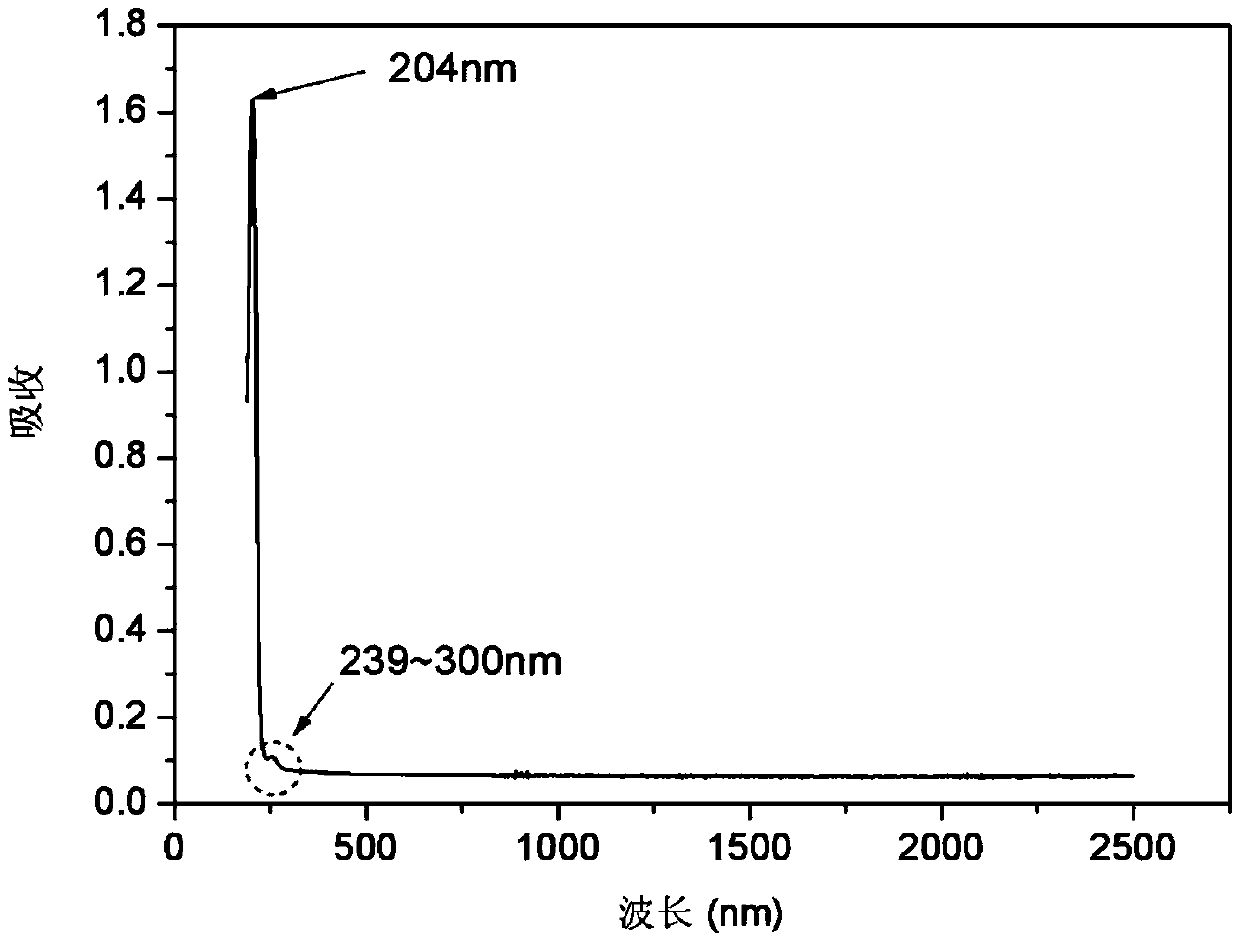

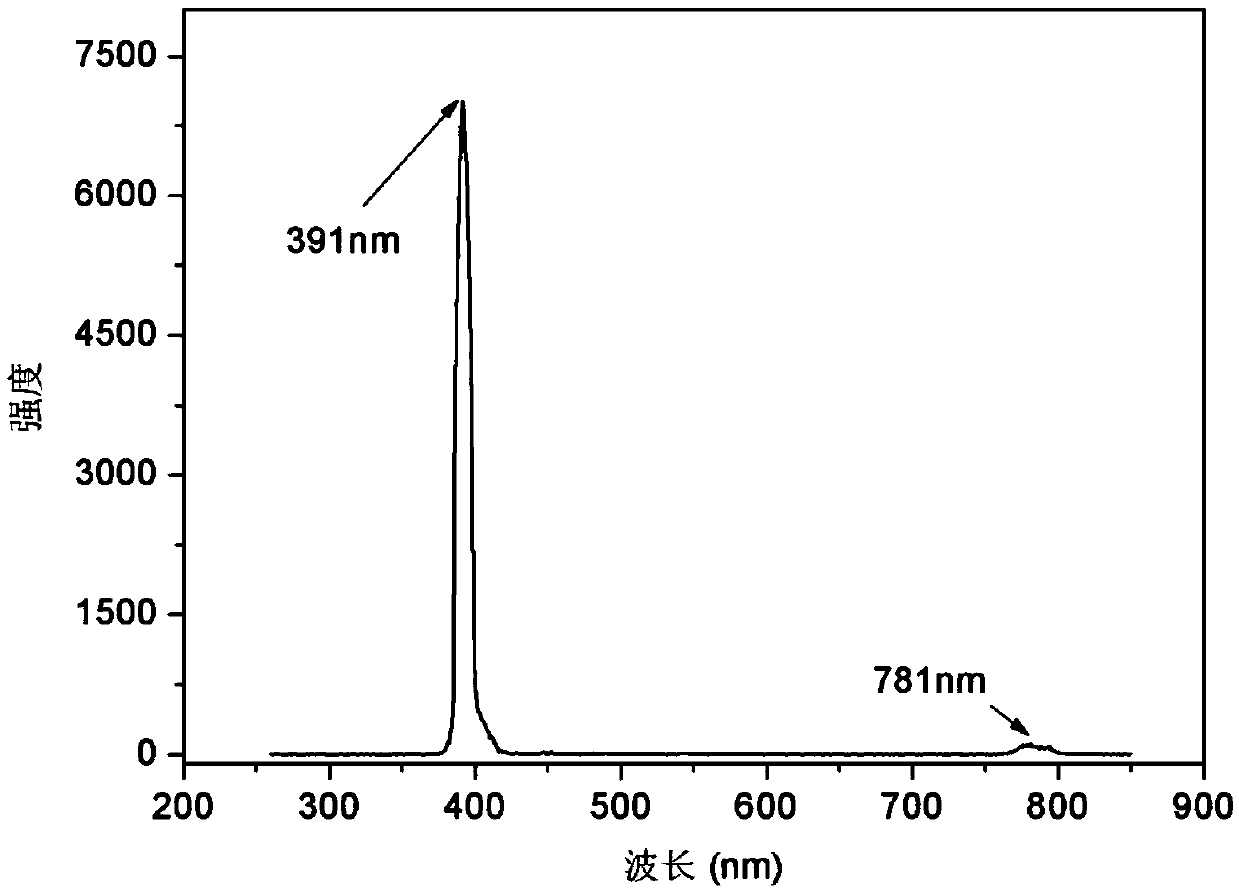

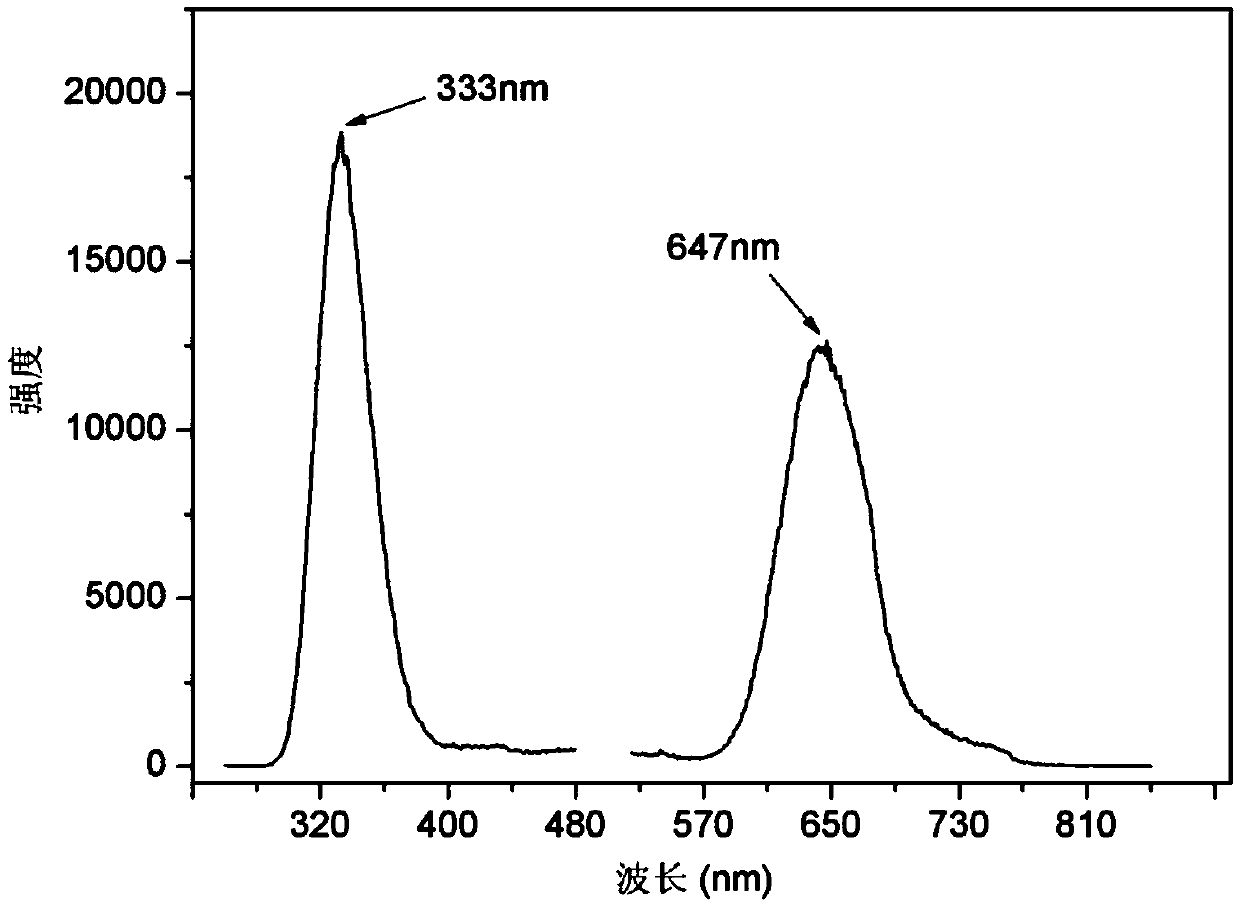

[0028] The C:Cu:Al that embodiment 1...

Embodiment 2

[0035] Weigh C, CuO and Al by x=0.25wt%, y=0.05wt% 2 o 3 Raw material 600g. Combine C and Al 2 o 3 Put it into a molybdenum crucible, put it into a high-temperature firing furnace protected by an inert atmosphere, raise the temperature at 180°C / h to 2050°C, keep it for 2 hours, and then cool it down to room temperature at 200°C / h. Then put CuO into the above-mentioned filled with C and Al 2 o 3 In the crucible of the sintered material, repeat the above-mentioned sintering process. Take out the prepared material from the crucible, place it in a tungsten crucible for crystal growth, and grow C:Cu:Al by temperature gradient method 2 o 3 crystals. A sapphire seed crystal in the orientation was put into the bottom of the crucible, and the crystal growth was carried out in an Ar gas environment. The melting rate of the raw material is 120°C / h, the crystallization rate of the melt is 1.5°C / h, and the cooling rate of the crystal is 25°C / h.

Embodiment 3

[0037] Weigh C, CuO and Al by x=0.5wt%, y=0.08wt% 2 o 3 Raw material 500g. Combine C and Al 2 o 3 Put it into a tungsten crucible, put it into a high-temperature firing furnace protected by an inert atmosphere, raise the temperature to 2030°C at 200°C / h, and cool it down to room temperature at 200°C / h after holding for 2 hours. Then put CuO into the above-mentioned filled with C and Al 2 o 3 In the crucible of the sintered material, repeat the above-mentioned sintering process. Take out the prepared material from the crucible, place it in an iridium gold crucible for crystal growth, and grow C:Cu:Al by pulling method 2 o 3 crystals. A sapphire crystal rod with a direction is selected as the seed crystal, and the crystal growth is carried out in an Ar gas environment. The crystal pulling speed is 1.2mm / h, the rotation speed is 15rpm, and the growth of the convex interface of the crystal is controlled. After loading the furnace → vacuuming → filling Ar gas → heating th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com