layered na 3 v 2 (po 4 ) 3 @rgo nanocomposites and their preparation methods and applications

A nanocomposite material, NH4H2PO4 technology, applied in the field of nanomaterials and electrochemistry, to achieve the effect of shortening the diffusion distance, improving electrochemical performance, excellent cycle stability and high rate characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

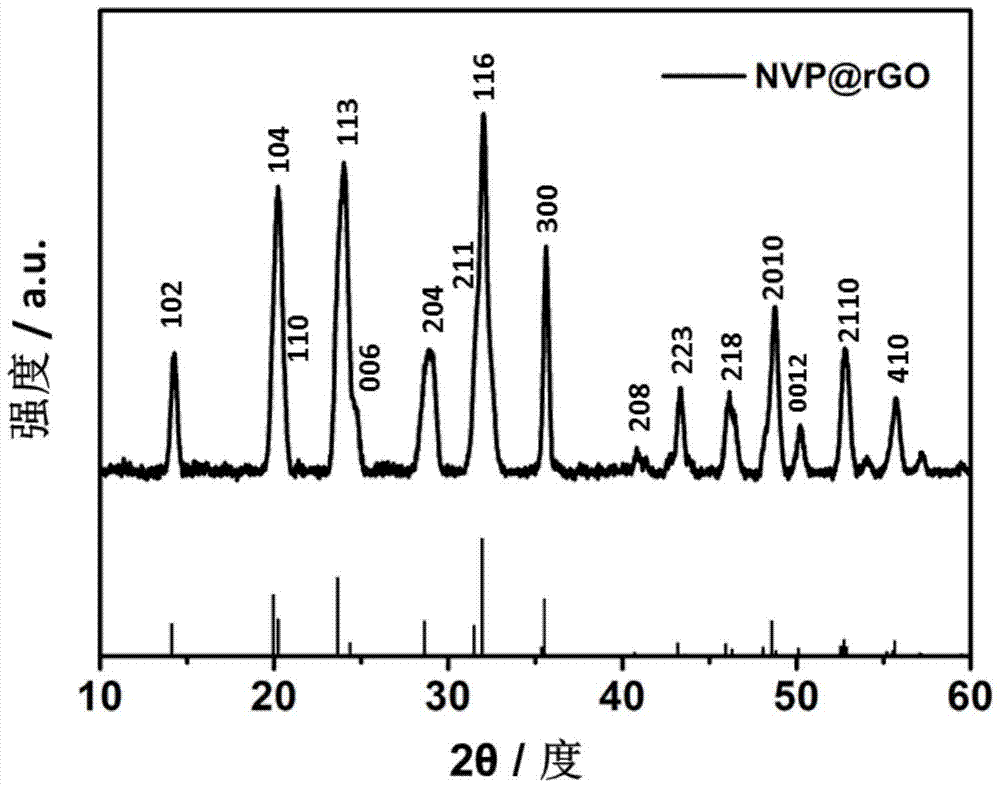

[0038] Layered Na 3 V 2 (PO 4 ) 3 The preparation method of @rGO nanocomposite material, it comprises the following steps:

[0039] 1) Add 0.75mmol Na 2 CO 3 , 1mmol V(C 5 h 7 o 2 ) 3 , 1.5mmol NH 4 h 2 PO 4 Dissolve in 40mL deionized water;

[0040] 2) ultrasonically treat the solution obtained in step 1) for 60 minutes, and then stir for 120 minutes in a water bath at 80°C;

[0041] 3) Transfer the light blue precursor mixture obtained in step 2) to a 50mL reactor, heat it with water at 180°C for 8 hours, and cool it down to room temperature naturally;

[0042] 4) Add 10 mg of graphene oxide to the green jelly-like gel obtained in step 3) and stir until uniformly dispersed;

[0043] 5) The uniformly mixed gel dispersion obtained in step 4) is dried by freeze-drying technology;

[0044] 6) After grinding the dried product obtained in step 5), in 750°C Ar / H 2 Calcined under the atmosphere for 6 hours, the heating rate was 2 °C / min, and the layered Na 3 V 2 (P...

Embodiment 2

[0050] Layered Na 3 V 2 (PO 4 ) 3 @rGO nanocomposite preparation method, which includes the following steps:

[0051] 1) Add 0.75mmol Na 2 CO 3 , 1mmol V(C 5 h7 o 2 ) 3 , 1.5mmol NH 4 h 2 PO 4 Dissolve in 40mL deionized water;

[0052] 2) ultrasonically treat the solution obtained in step 1) for 30 minutes, and then stir for 60 minutes in a water bath at 90°C;

[0053] 3) Transfer the light blue precursor mixture obtained in step 2) to a 50mL reactor, heat it with water at 180°C for 10 hours, and cool it down to room temperature naturally;

[0054] 4) Add 20 mg of graphene oxide to the green jelly-like gel obtained in step 3) and stir until evenly dispersed;

[0055] 5) The uniformly mixed gel dispersion obtained in step 4) is dried by freeze-drying technology;

[0056] 6) After grinding the dried product obtained in step 5), in 750°C Ar / H 2 Calcined under the atmosphere for 6 hours, the heating rate was 2 °C / min, and the layered Na 3 V 2 (PO 4 ) 3 @rGO nano...

Embodiment 3

[0059] Layered Na 3 V 2 (PO 4 ) 3 @rGO nanocomposite preparation method, which includes the following steps:

[0060] 1) Add 1.5mmol Na 2 CO 3 , 2mmol V(C 5 h 7 o 2 ) 3 , 3mmol NH 4 h 2 PO 4 Dissolve in 70mL deionized water;

[0061] 2) After ultrasonically treating the solution obtained in step 1) for 60 minutes, stir it in a water bath at 80°C for 60 minutes;

[0062] 3) Transfer the light blue precursor mixture obtained in step 2) to a 100mL reactor, heat it with water at 180°C for 8 hours, and cool it down to room temperature naturally;

[0063] 4) Add 30 mg of graphene oxide to the green jelly-like gel obtained in step 3) and stir until uniformly dispersed;

[0064] 5) The uniformly mixed gel dispersion obtained in step 4) is dried by freeze-drying technology;

[0065] 6) After grinding the dried product obtained in step 5), in 700°C Ar / H 2 Calcined under the atmosphere for 8 hours, the heating rate was 2 °C / min, and the layered Na 3 V 2 (PO 4 ) 3 @rGO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com