Fibrous structured amorphous silica including precipitated calcium carbonate, compositions of matter made therefrom, and methods of use thereof

A technology of amorphous silica and fiber structure, applied in fibrous fillers, fiber raw material processing, papermaking, etc., can solve the problems of fillers and/or pigments being limited, not developed, not recognized, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0104] Several process steps can be used in the preparation of the unique nanocomposite materials described herein. From the most basic point of view, there are two steps, such as Figure 25 The two pieces shown. In a first step, one or more selected synthetic silicate hydrates are prepared by hydrothermal reaction of a calcareous material, such as lime, with a siliceous material, such as quartz or diatomaceous earth ("DE"). In the second step, the freshly prepared one or more selected calcium silicate hydrates are carbonated under pressure to produce a nanocomposite comprising amorphous silica and additional crystalline calcium carbonate structure, the amorphous silica is generally formed in the form of a prior crystalline calcium silicate hydrate which in one embodiment occurs as an aragonite phase. In one embodiment, the process can be performed in a pressurized reactor.

[0105] The preparation of suitable nanocomposite materials involves reacting carbon dioxide with sy...

Embodiment 1

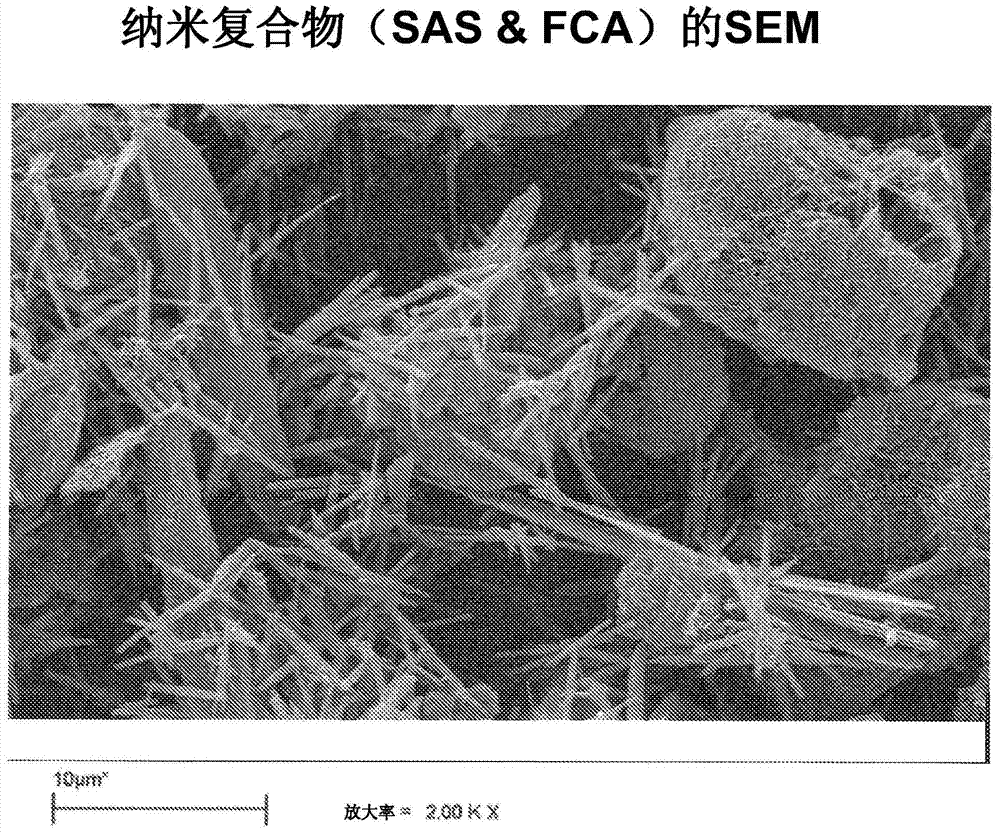

[0182] Example 1 - Manufacture of novel nanocomposites (SAS & FCA)

[0183] step 1 : Preparation of Synthetic Calcium Silicate Hydrate-Xonotlite

[0184]Initially, 117.4 g of 1 / 2" spin pebble lime (from Graymont Lime Co.) was accurately weighed and aged in 350 mL of ultrapure water prepared by reverse osmosis treatment. The curing reaction was exothermic and caused slurry The temperature was raised to near boiling. When the slurry temperature was very close to boiling and before a large amount of water evaporated, an additional 90 ml of water was added to dilute and cool the slurry at the same time. The slurry was then stirred for 30 minutes to ensure ripening was complete. Then, The slurry was screened through a 100 mesh screen. The slurry was then transferred to a 5 L autoclave and tested for lime availability according to ASTM method C25 entitled "Standard Test Methods for Chemical Analysis of Limestone, Quicklime, and Hydrated Lime" Weigh about 137.2g of fine fused ca...

Embodiment 2

[0220] Example 2 - Manufacture of novel nanocomposites (SAS & FCA)

[0221] step 1 : Preparation of Synthetic Calcium Silicate Hydrate-Xonotlite

[0222] The heterogeneous calcium silicate hydrate was formed by means of the hydrothermal reaction of lime and silica as described in Example 1. The difference from Example 1 is that the silica source used in Example 2 is non-calcined diatomite or natural diatomite. The sample is labeled as batch #MN-2. The process conditions used to prepare the samples identified as Batch #MN-2 are given in Table 12. The pigment properties of the sample identified as Lot #MN-2 are given in Table 13.

[0223] Table 12: Process conditions for xonotlite (MN-2) formation

[0224]

[0225] Table 13: Properties of xonotlite (MN-2)

[0226] batch#

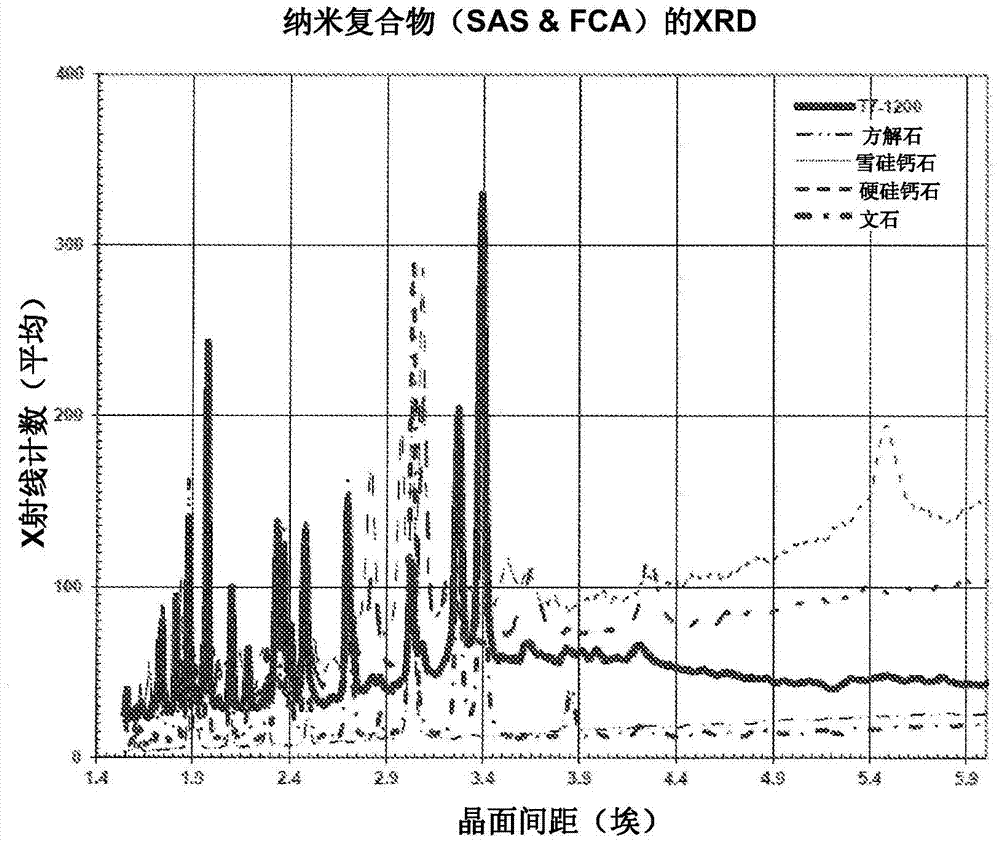

[0227] A picture of the XRD pattern of this crystalline xonotlite sample is at Figure 27 given in. The SEM photograph of the crystalline xonotlite sample is in Figure 26 given in.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com