Method for decoloration, debitterization and deodorization of fish protein liquid

A fish protein and debittering technology, which is applied in the field of protein separation and purification, can solve the problems that the irradiation method is not suitable for large-scale application in workshops, the effect of debittering and deodorization is not very ideal, and the environmental pollution of workshop production, so as to improve the decolorization and debittering. Odorless efficiency, mild and safe treatment process, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

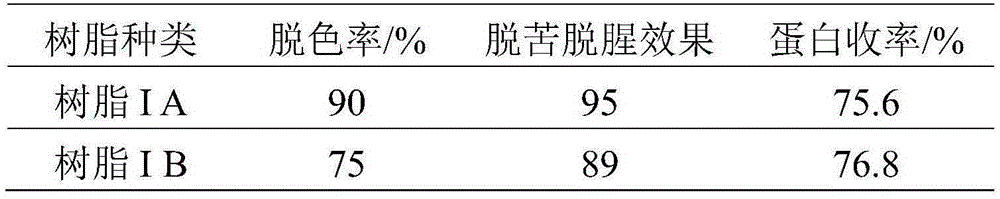

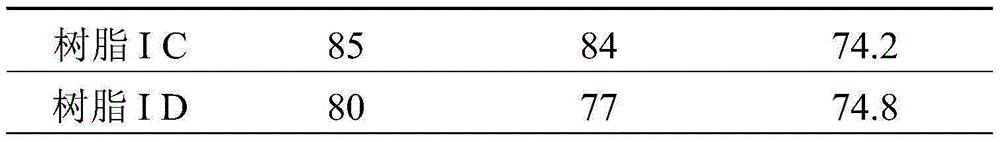

Embodiment 1

[0033] After the fish skin is enzymatically hydrolyzed, a fish skin protein solution with a protein concentration of 7% and a comprehensive sensory value of 40 for bitter smell is obtained. Soak 150ml of resin I in 200ml of 90% ethanol solution to activate the resin, then rinse with water until there is no ethanol smell, and pack it into a column for later use. Soak 100ml of resin II with 200ml of 3% HCl solution for 2h, and then rinse with water until the pH is 5. Then filter 2L of fish skin protein solution to remove residue, pass it through a resin column at 20°C for a controlled time of 2 hours, and collect the permeate, which is the fish skin protein solution after decolorization, bitterness and fishy smell. The resin I was eluted with 300ml of ethanol solution with a volume fraction of 90%, and the elution time was 2h, and the eluate I was collected. After elution, rinse resin I with water until there is no ethanol smell. Distill the waste ethanol solution and eluent I...

Embodiment 2

[0035] After the fish steak is enzymatically hydrolyzed, a fish steak protein solution with a protein concentration of 5% is obtained, and the comprehensive sensory value of bitterness is 30. Soak 200ml of resin I with 250ml of ethanol solution with a volume fraction of 95% to activate the resin, then rinse with water until there is no ethanol smell, and pack it into a column for later use. Soak 150ml of resin II with 200ml of 4% HCl solution for 2h, and then rinse with water until the pH is 5. Then filter 5L fish steak protein solution to remove the residue, pass it through the resin column at 20°C for a controlled time of 2 hours, and collect the permeate, which is the fish steak protein solution after decolorization, bitterness and fishy smell. The resin I was eluted with 400ml of ethanol solution with a volume fraction of 95%, and the elution time was 2h, and the eluate I was collected. After elution, rinse resin I with water until there is no ethanol smell. Distill the ...

Embodiment 3

[0037] After the fish meat is enzymatically hydrolyzed, a fish protein solution with a protein concentration of 8% and a comprehensive sensory value of 35 for bitter and fishy smell is obtained. Soak 300ml of resin I with 350ml of 90% ethanol solution to activate the resin, then rinse with water until there is no ethanol smell, and pack it into a column for later use. Soak 150ml of resin II with 200ml of 4% HCl solution for 2h, and then rinse with water until the pH is 6. Then filter 4L of the fish protein solution to remove the residue, pass it through the resin column at 20°C for a controlled time of 2 hours, and collect the permeate, which is the fish protein solution after decolorization, bitterness and fishy smell. The resin I was eluted with 600ml of ethanol solution with a volume fraction of 90%, and the elution time was 2h, and the eluate I was collected. After elution, rinse resin I with water until there is no ethanol smell. Distill the waste ethanol solution and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com