Adsorption film mixing three metallic oxides and preparation method thereof and method for measuring fluorinion based on gradient diffusion thin film technology

An adsorption film and oxide technology, applied in the direction of alkali metal oxides/hydroxides, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of limitation of fluoride ion detection means and difficulty in achieving accurate measurement, etc., and reach the scope of use The effect of wide, good adsorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

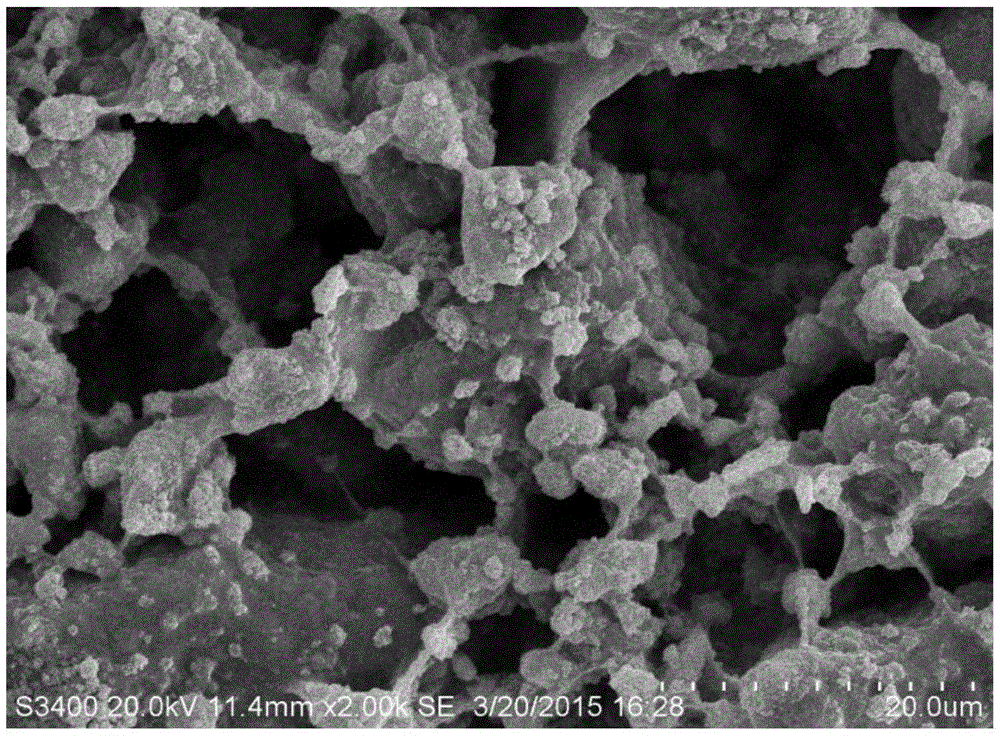

[0056] First, particles of mixed oxides of three metals (iron, aluminum and cerium) are prepared:

[0057] (1) Dissolve 2.78g of ferrous sulfate, 4.86g of aluminum sulfate, 4.04g of cerium sulfate in 100mL of pure water to prepare a mixed solution, wherein the mixed solution contains 0.1mol / L iron ion, 0.2mol / L aluminum ion and 0.1mol / L cerium ion.

[0058] (2) Regulate the pH value of the mixed solution of step (1) with saturated sodium hydroxide solution and keep stirring, until the pH value reaches 8, collect a large amount of yellowish-brown precipitate that occurs, and repeatedly wash the yellow precipitate with pure water, and remove it in 3577g Centrifuge for 10 min under the condition, measure the pH value of the supernatant, skim off the supernatant, repeat the above operation until the pH value of the supernatant drops to 6.5.

[0059] (3) Dry the cleaned brownish-yellow precipitate in an oven at 65°C for 24 hours, then calcinate it in a muffle furnace at 300°C for...

Embodiment 2

[0079] A kind of preparation method of the adsorption film that mixes three kinds of metal oxides in the present embodiment is basically the same as embodiment one, the difference is: the solution that prepares mixed three kinds of metal oxide particles is by dissolving 5.56g ferrous sulfate, 9.72g sulfuric acid Aluminum, prepared by adding 8.08g of cerium sulfate particles to 100mL of pure water, wherein the solution contains 0.2mol / L iron ion, 0.4mol / L aluminum ion and 0.2mol / L cerium ion. A method for measuring fluoride ions in a water environment based on gradient diffusion film technology is basically the same as in Example 1, except that this example is simulated wastewater with different pH values prepared in the laboratory (the pH range is 3.15 to 9.12). The total volume is 2L, the fluoride ion content is 1mg / L, and the nitrate ion content is 0.01mol / L. The implementation steps are: place the prepared DGT device in the prepared simulated wastewater for 4 hours, then ...

Embodiment 3

[0083] The preparation method of a kind of adsorption film that mixes three kinds of metal oxides in the present embodiment is basically the same as embodiment one, the difference is: the solution that prepares mixed three kinds of metal oxide particles is by dissolving 1.91g ferrous chloride, 4.01g Aluminum chloride, prepared by adding 4.23g of cerium chloride particles to 100mL of pure water, wherein the solution contains 0.15mol / L iron ion, 0.3mol / L aluminum ion and 0.15mol / L cerium ion. A method for measuring fluoride ions in a water environment based on gradient diffusion film technology is basically the same as in Example 1, the difference is that this example is a laboratory preparation of different ionic strengths (0~200mmol / LNO 3 - ) simulated wastewater, the total volume of wastewater is 2L, the fluoride ion content is 1mg / L, and the pH value is 6. The determination steps are basically the same as in Example 2, except that the amount of sodium hydroxide eluent is 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com