Preparation method of attapulgite-based molecular imprinting type CO2 adsorbing material

A technology of molecular imprinting and adsorption materials, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., can solve the problem of less attapulgite clay, achieve large adsorption capacity, large adsorption selectivity, and low regeneration energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Prepare composite adsorbent according to the following steps

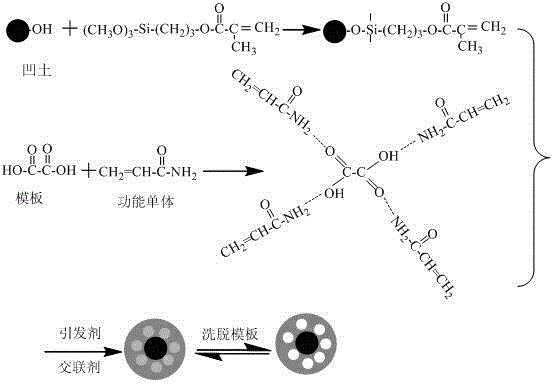

[0031] (1) Dry the attapulgite clay at 105°C and crush it through 200 meshes; add 3g of dried attapulgite clay and 100ml toluene into the container, and add 3ml of silane coupling agent γ-(methacryloyl Oxygen)propyltrimethoxysilane, react in ultrasonic at 40°C for 50 minutes; react in a constant temperature oil bath with magnetic stirring at 40°C for another 5 hours; the reaction product is filtered, washed, dried, and Pulverized to obtain modified attapulgite clay;

[0032] (2) Put 2mmol of acrylamide and 1mmol of acetic acid in the reactor, add 10mmol of acetonitrile, seal it, and disperse it ultrasonically for 10 minutes, so that the whole system is fully dissolved and mixed evenly, and the system is left at room temperature for 12 hours to make Template molecules and functional monomers fully interact to form a stable complex;

[0033] (3) Add 10mmol crosslinker ethylene glycol dimethacry...

Embodiment 2

[0035] Embodiment 2: prepare composite adsorbent according to the following steps

[0036] (1) Dry the attapulgite clay at 105°C and crush it through 200 meshes; add 3g of dried attapulgite clay and 120ml of absolute ethanol into the container, and add 4ml of silane coupling agent 3-aminopropyl during stirring Triethoxysilane, 45 ° C ultrasonic reaction for 30 minutes; 50 ° C magnetically stirred constant temperature oil bath for another 4 hours; the reaction product was successively filtered through toluene, absolute ethanol and deionized water, washed, dried, and pulverized to prepare Obtain modified attapulgite clay;

[0037] (2) Put 4mmol of acrylamide and 1mmol of oxalic acid in the reactor, add 15mmol of acetonitrile:toluene mixed solvent with a volume ratio of 1:1, seal, and ultrasonically disperse for 15 minutes, so that the entire system is fully dissolved and mixed evenly. Let the system stand at room temperature for 24 hours, so that the template molecules and func...

Embodiment 3

[0040] Embodiment 3: prepare composite adsorbent according to the following steps

[0041] (1) Dry the attapulgite clay at 105°C and crush it through 200 meshes; add 3g of dried attapulgite clay and 150ml of toluene into the container, and add 5ml of silane coupling agent 3-aminopropyltriethyl during stirring Oxysilane was reacted in ultrasonic at 45°C for 30 minutes; then reacted in a constant temperature oil bath with magnetic stirring at 60°C for 3 hours; Sexual attapulgite clay;

[0042] (2) Put 8mmol of acrylamide and 1mmol of oxalic acid in the reactor, add 20mmol of acetonitrile solvent, seal it, and ultrasonically disperse it for 20 minutes, so that the whole system is fully dissolved and mixed evenly, and the system is allowed to stand at room temperature for 18 hours, the template molecules and functional monomers can fully interact to form a stable complex;

[0043] (3) Add 30mmol crosslinker N,N'-methylenebisacrylamide, 0.5mol initiator azobisisobutyronitrile and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com