Laser Welding Method for Guide Sheath of Guide Tube in Nuclear Reactor

A laser welding and nuclear reactor technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as complicated operation steps, low efficiency, and potential safety hazards, and achieve simple welding process, fast welding speed, and safe working environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

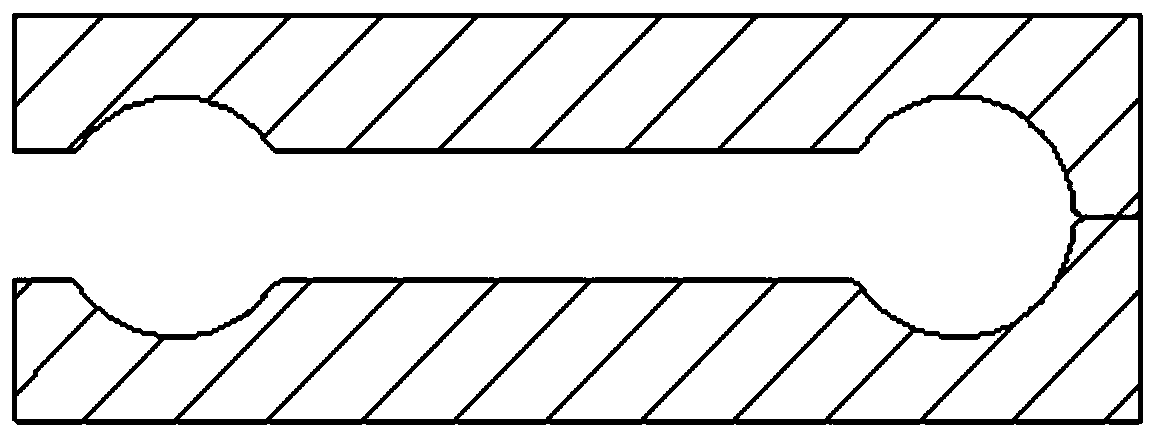

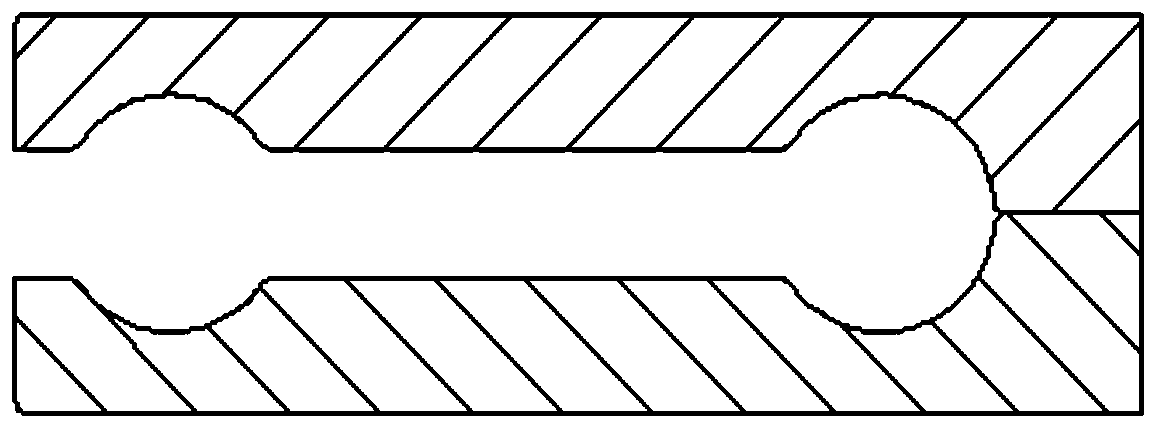

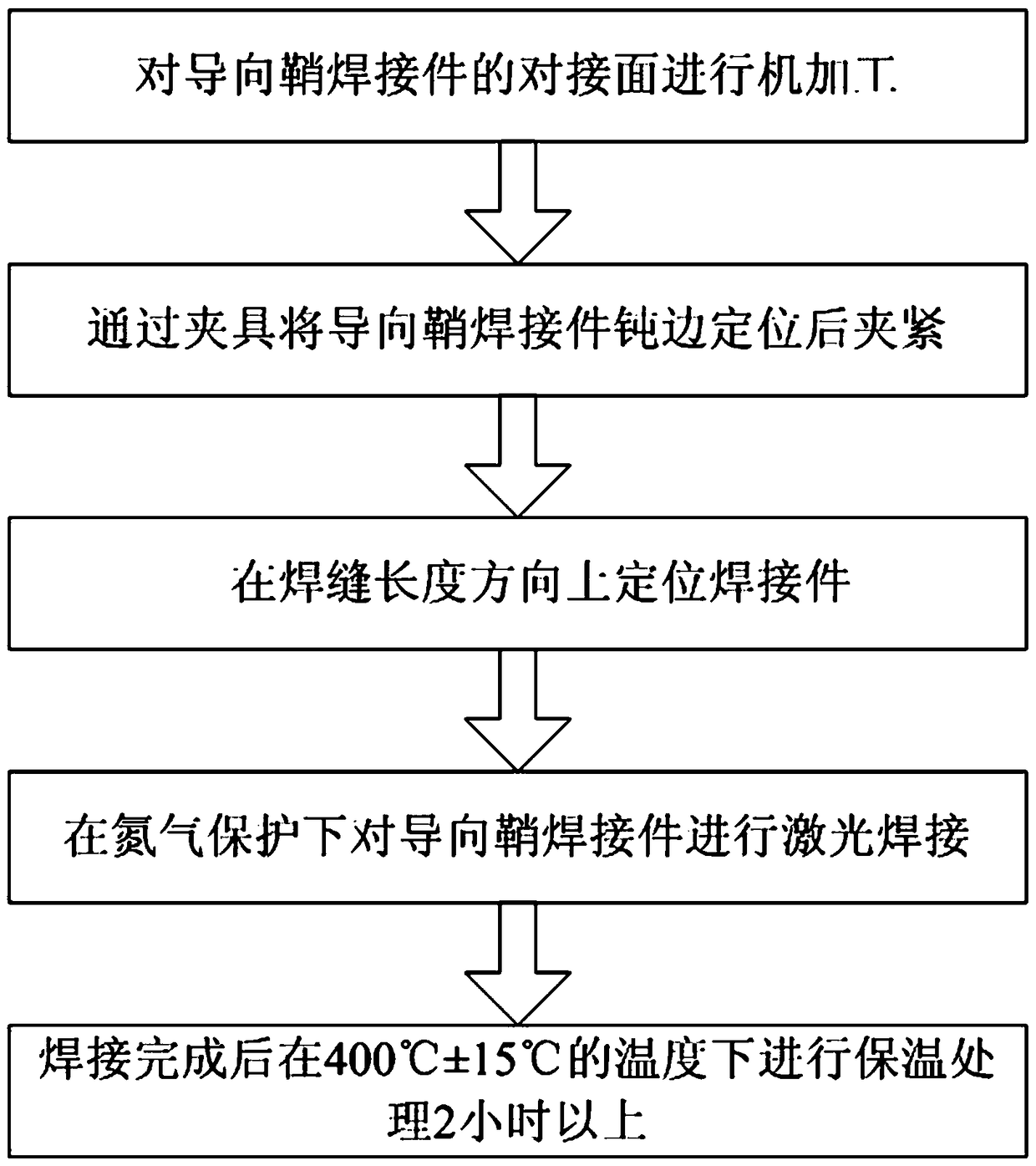

[0029] The specific implementation of the laser welding method for the guide sheath of the inner guide tube of the nuclear reactor of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] Laser welding is a high-energy beam welding method. Compared with traditional electrode arc welding (SMAW), non-melting electrode gas shielded welding (GTAW) and other welding methods, laser welding has high energy density of heat source, high welding speed, low heat input and deep weld seam. The width ratio is large, the weld structure is uniform and compact, the joint performance is excellent, and it is easy to control the amount of welding deformation and the uniformity of welding deformation. The guide cylinder is an important part of the internal components of the pressurized water reactor. It is installed on the upper internal components and guides the control rods. It requires high manufacturing precision and is made of nuclear g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com