Cellulose wastewater pretreatment apparatus and application thereof

A pretreatment device, cellulose technology, applied in natural water treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem that the quality of operation and maintenance personnel is difficult to meet the requirements of complex process operation, and the investment cost is difficult for enterprises to accept , biochemical treatment difficulties and other problems, to achieve the effect of saving construction investment and operation investment, saving raw materials, and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

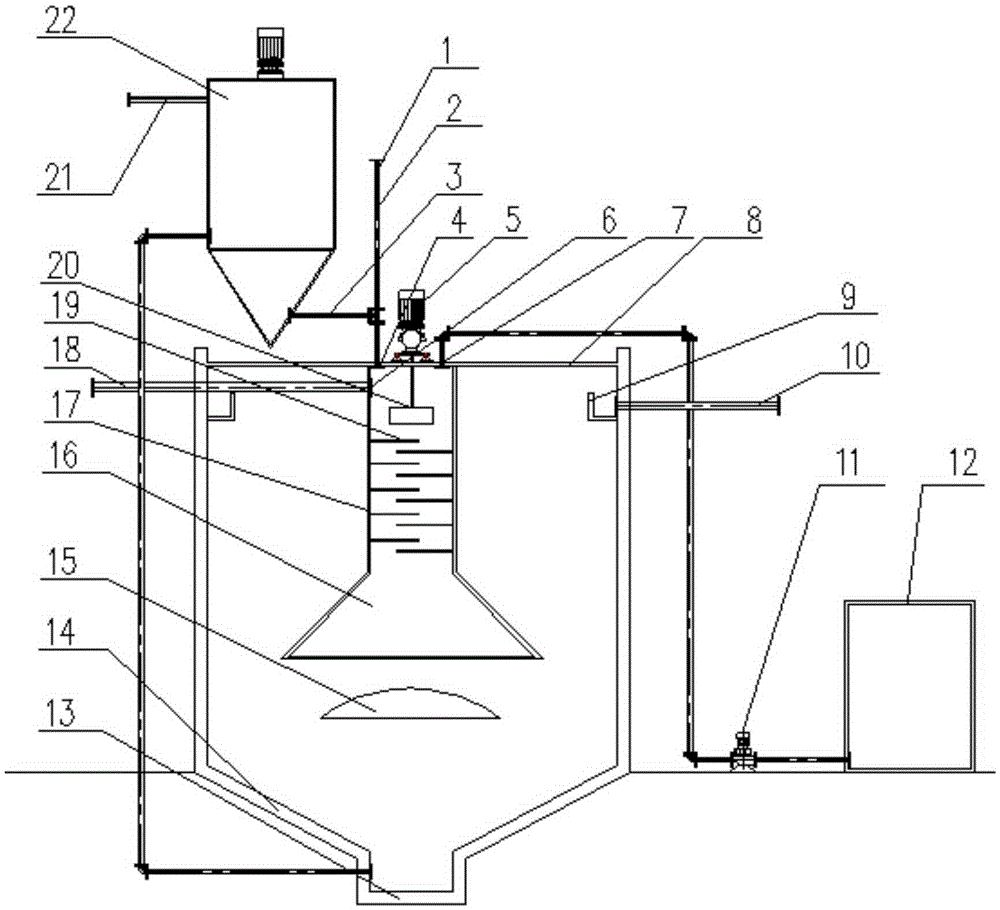

[0027] Hereinafter, the present invention will be further described in detail by taking the embodiment of the accompanying drawings as an example. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0028] The reverse flocculation method mentioned in this patent is different from the traditional method of adding flocculants to produce flocs in wastewater and settling and separating them. The basis for the generation of flocs is the return sludge in the subsequent biochemical treatment process. The macromolecular cellulose plays the role of adsorption and bridging. In the reverse flocculation method, the addition of flocculation nuclei increases the proportion of flocs and increases the power of sedimentation. Since the flocs have a relatively small proportion of reflux sludge, the sedimentation effect of the flocs is not good, so the flocculation nucleus is added to enhance the effect of gravity sett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com