High-alkali flyash continuous fibers and preparing method thereof

A continuous fiber, fly ash technology, applied in glass manufacturing equipment, manufacturing tools and other directions, can solve the problem of high alkali content, achieve the effect of simple formula and expand the value of development and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

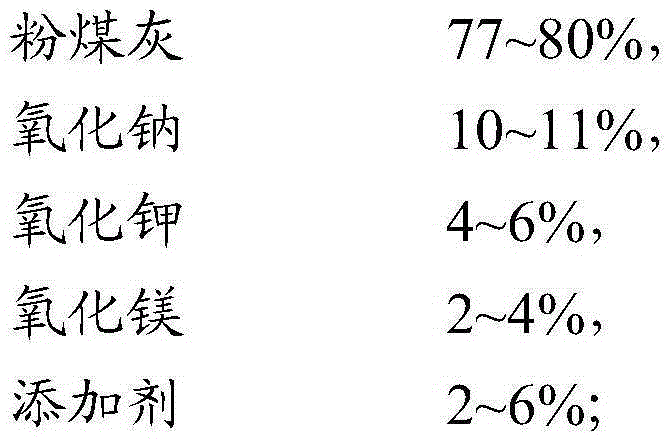

[0027] S1, raw material synthesis: mix according to the following ratio;

[0028]

[0029] The fly ash is the fly ash of the power plant in Dalian Development Zone.

[0030] S2. Metering and feeding: the above materials are mixed and transported to the flame pool kiln or electric melting furnace with the feeder; melted at 1650 ° C for 2 hours to obtain a clarified liquid slurry.

[0031] S3. Fiber preparation: the liquid slurry made by the above-mentioned calcination flows to the porous bushing plate through the feeder channel, and the temperature is lowered to 1400°C. An automatic tube-changing wire drawing machine is adopted. Temperature control, page control, and bushing board control are mature technologies, and the wire drawing machine is automated. Controlled, pulled into continuous fibers of high alkalinity fly ash.

Embodiment 2

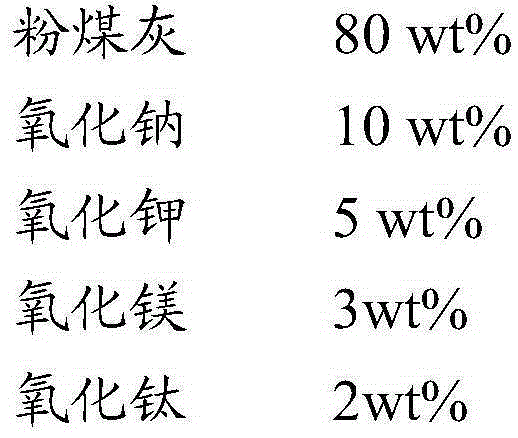

[0033] S1, raw material synthesis: mix according to the following ratio;

[0034]

[0035] The fly ash is the fly ash of the power plant in Dalian Development Zone.

[0036] S2. Measuring and feeding: the above materials are mixed and transported to the flame pool kiln or electric melting furnace with the feeder; melted at 1600 ° C for 2.5 hours to obtain a clarified liquid slurry.

[0037] S3. Fiber preparation: the liquid slurry made by the above-mentioned calcination flows to the porous drain plate through the material channel, and the temperature is lowered to 1370°C. An automatic tube changing wire drawing machine is adopted. Temperature control, page control, and drain plate control are mature technologies, and the wire drawing machine is automated. Controlled, pulled into continuous fibers of high alkalinity fly ash.

Embodiment 3

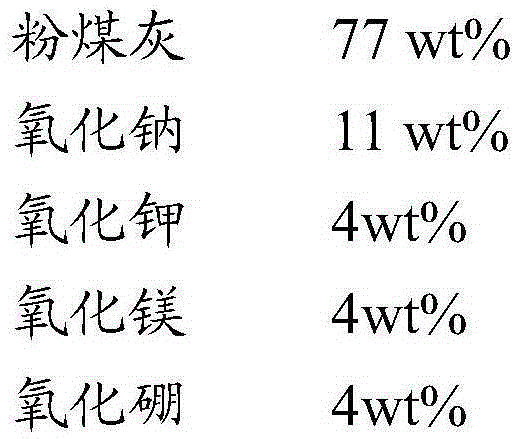

[0039] S1, raw material synthesis: mix according to the following ratio;

[0040]

[0041]

[0042] The fly ash is the fly ash of the power plant in Dalian Development Zone.

[0043] S2. Measuring and feeding: the above materials are mixed and transported to the flame pool kiln or electric melting furnace with the feeder; melted at 1600 ° C for 3 hours to obtain a clarified liquid slurry.

[0044] S3. Fiber preparation: the slurry made by the above-mentioned calcination flows to the porous bushing plate through the material channel, and the temperature is lowered to 1350°C. An automatic tube-changing wire drawing machine is adopted. Temperature control, page control, and bushing board control are mature technologies, and the wire drawing machine is automated. Controlled, pulled into continuous fibers of high alkalinity fly ash.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com