High-frost-resistant hydraulic concrete for high elevation regions

A technology of hydraulic concrete and high frost resistance, applied in the field of concrete, can solve the problems that concrete is easily damaged by freezing and thawing, buildings cannot function, and affect safe use, etc., and achieves important engineering application prospects, reduces engineering costs, and guarantees resistance to Effects of Freeze Durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing high frost-resistant hydraulic concrete in high-altitude areas, comprising the following steps:

[0035] (1) Clear design indicators

[0036] Concrete used in a water conservancy project in Tibet, with an altitude of 3300km, the design requires a strength grade of C9025 and a frost resistance grade of F200.

[0037] (2) Concrete raw materials and mix ratio

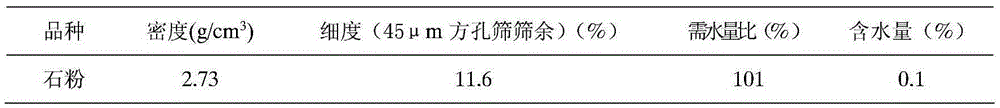

[0038] Raw materials include Huaxin 42.5 medium-heat Portland cement, local limestone powder, natural artificial mixed aggregate, Jiangsu Bote JM-II high-performance water reducer and GYQ air-entraining agent. The test results of stone powder quality are shown in Table 1.1.

[0039] Table 1.1 Stone powder quality inspection results

[0040]

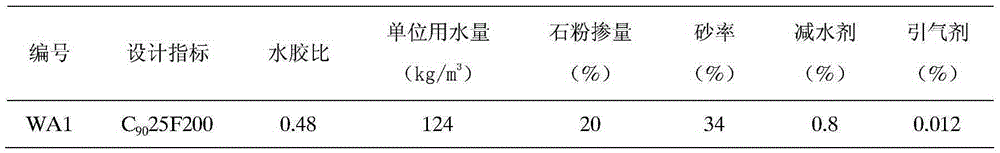

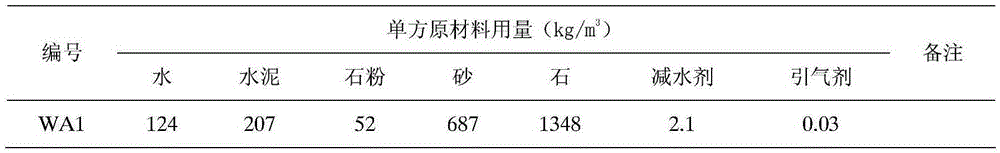

[0041] According to DL5330 "Code for Design of Mixture Proportion of Hydraulic Concrete", the calculated configuration strength of C9025 concrete is 31.6MPa. Combined with the absolute volume method, the concrete mix ratio and the amount of raw mat...

Embodiment 2

[0055] A method for preparing high frost-resistant hydraulic concrete in high-altitude areas, comprising the following steps:

[0056] (1) Clear design indicators

[0057] Concrete used in a water conservancy project in Tibet, with an altitude of 3300km, the design requires a strength grade of C9025 and a frost resistance grade of F200.

[0058] (2) Concrete raw materials and mix ratio

[0059] Raw materials include Huaxin 42.5 medium-heat Portland cement, Gansu Shizuishan Class II fly ash, natural artificial mixed aggregate, Jiangsu Bote JM-II high-performance water reducer and GYQ air-entraining agent. The test results of fly ash quality are shown in Table 2.1.

[0060] Table 2.1 Fly ash quality inspection results

[0061]

[0062] According to DL5330 "Code for Design of Mixture Proportion of Hydraulic Concrete", the calculated configuration strength of C9025 concrete is 31.6MPa. Combined with the absolute volume method, the concrete mix ratio and the amount of raw mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com