Water-tolerant and mould-proof putty powder for internal wall and use method of water-tolerant and mould-proof putty powder

A putty powder and anti-mildew technology, applied in the field of building materials, can solve problems such as damage to human health and affect the appearance of walls, and achieve the effects of strong sterilization, anti-mildew, good water and alkali resistance, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

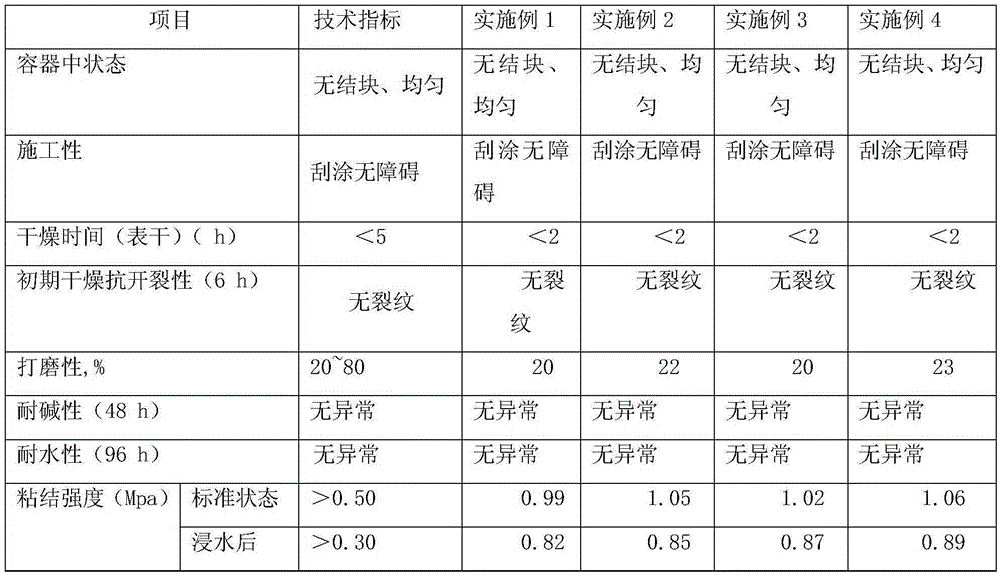

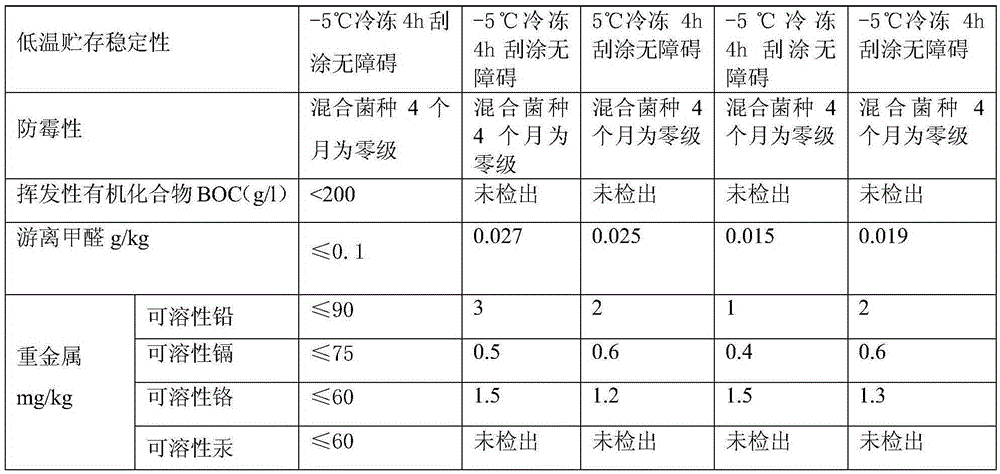

Embodiment 1

[0026] A water-resistant and anti-mildew putty powder for interior walls, comprising the following parts by weight uniformly mixed with raw materials: 100 parts of Albo white cement, 200 parts of gray calcium, 8 parts of anti-mold agent, 3 parts of hydroxypropyl methylcellulose, WACKER rubber powder 5010 is 15 parts, heavy calcium 600 parts, defoamer 1 part, starch ether 1 part, retarder 2 parts, thixotropic lubricant 4 parts, the gray calcium particle size is 500 meshes, The anti-mold agent is a compound containing phenolic compounds, the heavy calcium has a particle size of 500 mesh, and the anti-foaming agent is a mixture of liquid hydrocarbons, polyethylene glycol and amorphous silicon dioxide, The starch ether is hydroxypropyl starch ether, and the retarder is a polyhydroxy compound.

Embodiment 2

[0028] A water-resistant and mildew-resistant putty powder for interior walls, comprising the following parts by weight of uniformly mixed raw materials, 120 parts of Albo white cement, 220 parts of gray calcium, 3 parts of anti-mold agent, and 5 parts of hydroxypropyl methylcellulose. WACKER rubber powder 5010 is 18 parts, heavy calcium 660 parts, defoamer 2 parts, starch ether 3 parts, retarder 2 parts, thixotropic lubricant 7 parts, the gray calcium particle size is 600 meshes, The anti-mold agent is a compound containing an organometallic compound, the particle size of the heavy calcium is 600 mesh, the defoaming agent is an organosilicon defoaming agent, and the starch ether is carboxymethyl starch ether. The retarder is high sugar lignosulfonate.

Embodiment 3

[0030] A water-resistant and mildew-resistant putty powder for interior walls, comprising the following parts by weight of uniformly mixed raw materials, 200 parts of Albo white cement, 300 parts of gray calcium, 8 parts of anti-mold agent, and 8 parts of hydroxypropyl methylcellulose, WACKER rubber powder 5010 is 30 parts, heavy calcium 800 parts, defoamer 5 parts, starch ether 5 parts, retarder 5 parts, thixotropic lubricant 10 parts, the gray calcium particle size is 600 meshes, The anti-mold agent is a compound containing halogen-containing compounds, the particle size of the heavy calcium is 600 meshes, and the defoamer is a silicone defoamer and a mineral oil defoamer in a weight ratio of 1:1 The starch ether is a cationic starch ether, and the retarder is a derivative of hydroxycarboxylate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com