Room temperature magnetic refrigeration alloy material and preparation method therefor

An alloy material and magnetic refrigeration technology, applied in the field of metallurgy, can solve the problems of high Curie temperature, large thermal hysteresis, small adjustable temperature width, etc., and achieve the effects of small thermal hysteresis, large adjustable temperature area and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

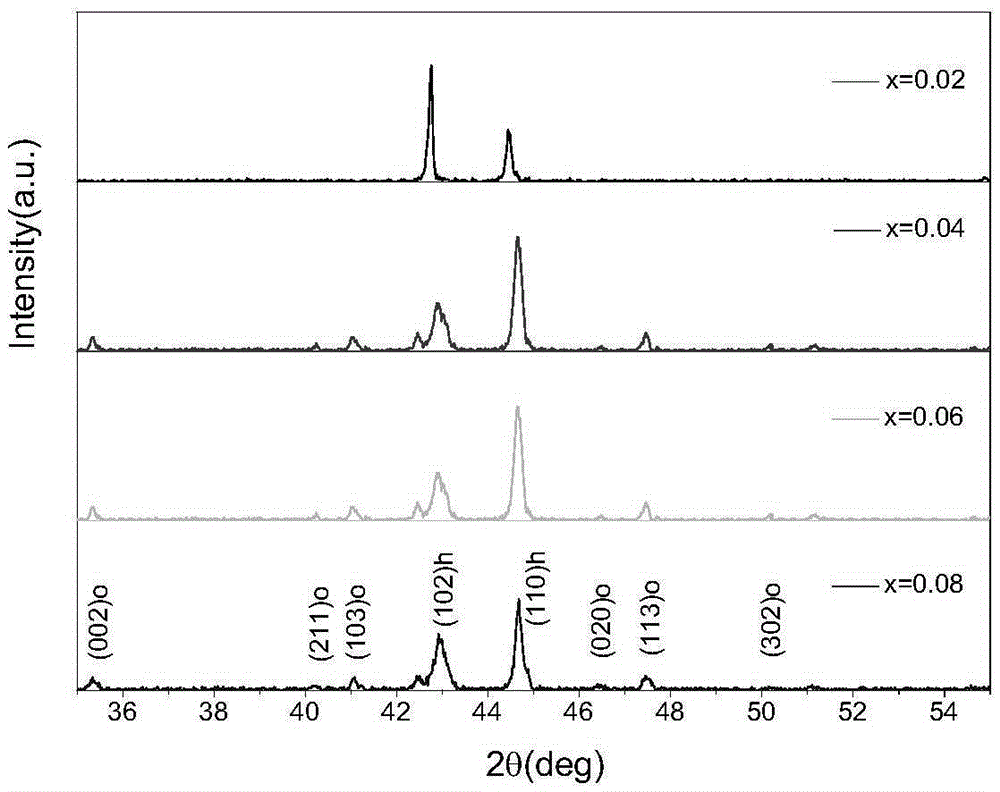

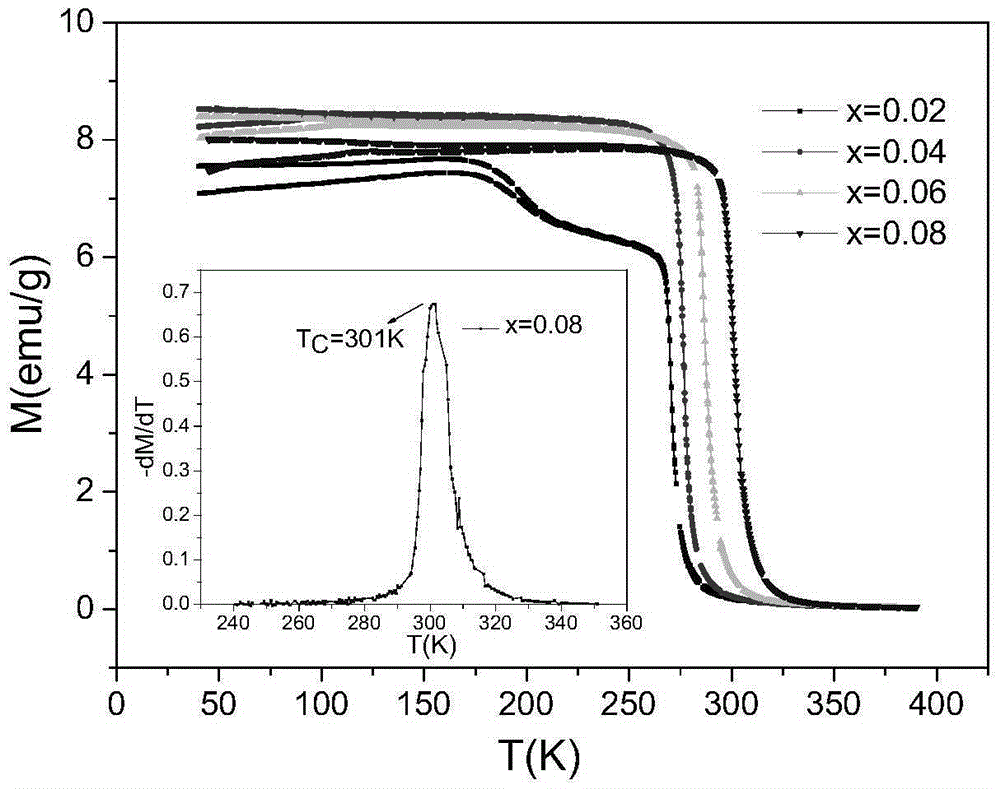

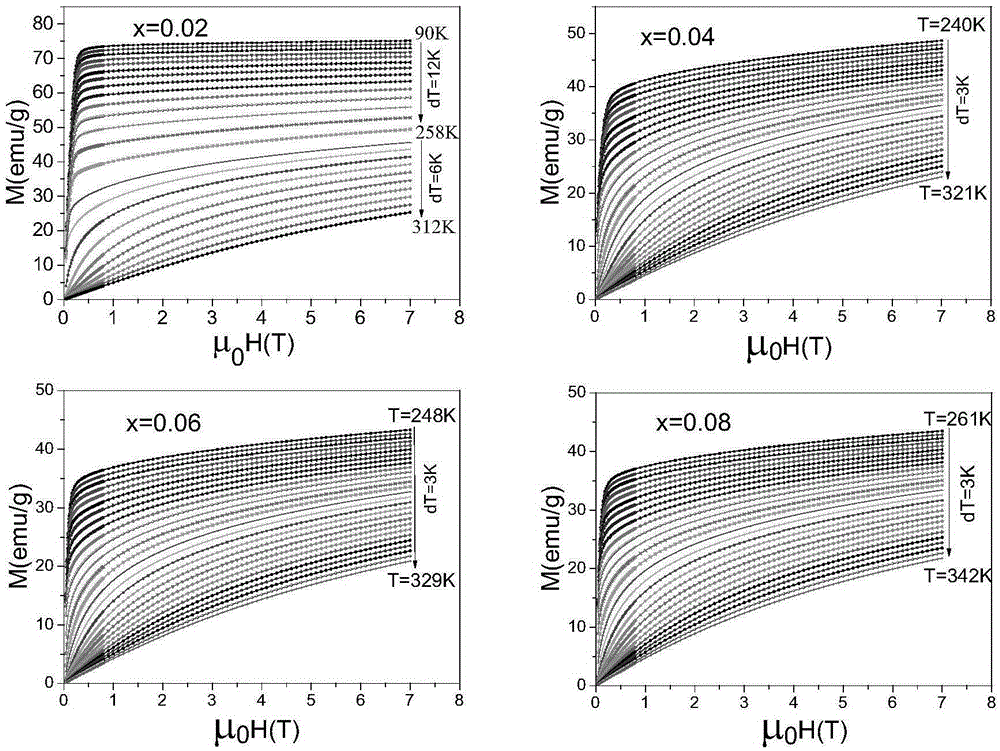

[0024] The purity of the raw materials used is 99.9% Mn, 99.95% Al, 99.9% Co, 99.99% Ge, each powder is weighed according to the mass percentage, the mass percentage of the manganese element is 33.3-34.4%, and the mass percentage of the aluminum element is 0.6-2.7% %, the mass percentage of cobalt element is 32.8-33.3%, and the mass percentage of germanium element is 30.2-32.7%.

[0025] The alloy is smelted in a vacuum electric arc furnace, and various elements are added into the vacuum electric arc furnace. Before the alloy is smelted, the mechanical pump is first used to evacuate the vacuum below 5Pa, and the molecular pump is turned on to evacuate again to below 10 Pa. -4Pa, inject high-purity argon gas (99.999%) with a pressure of 10Pa, repeat the above vacuum pumping and gas washing operation steps twice, use a current of about 30A to start a fire, move the electrode to the top of the sample and about 0.5cm away from the sample, and slowly The current is adjusted to abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com