3D printing rapid forming method of food

A 3D printing and forming method technology, applied in the field of food processing, can solve the problems of not providing structural strength, complicated processing steps, and inability to be used, so as to achieve the effect of retaining flavor and nutrients, reducing maintenance workload, and increasing the field of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The rapid prototyping method of food 3D printing described in the present invention comprises the following steps:

[0029] 1) Fully mix the food material with the forming agent A, wherein the forming agent A is an edible natural gum, which is a combination of one or more of sodium alginate, potassium alginate, and carrageenan, and the concentration range is It is 0.5%-3.0% (w / v), and sodium alginate is preferred in this embodiment, the concentration is 1%. If the ingredients are solid ingredients, they need to be minced before mixing with forming agent A.

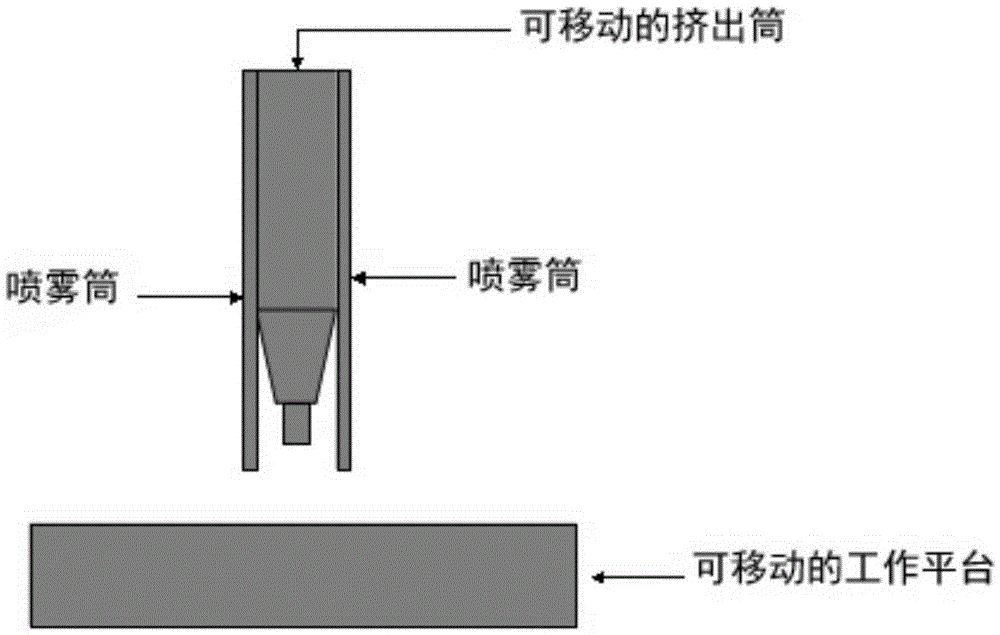

[0030] 2) Put the mixture of food material and molding agent A in the extrusion barrel of the nozzle of the 3D printer, and place the molding agent B in the spray barrel of the 3D printer, wherein the molding agent B is an edible calcium salt solution, which is gluconic acid One or more combinations of calcium, calcium lactate, and calcium chloride have a concentration ranging from 0.5% to 5.0% (w / v), and calcium c...

Embodiment 2

[0037] The difference from Example 1 is that the molding agent A used in this example is a mixed material of 1% sodium alginate and 0.5% carrageenan, and its reaction mechanism is as follows:

[0038] (sodium alginate + carrageenan) (forming agent A) + calcium chloride (forming agent B) → forming entity

[0039] Carrageenan, also known as carrageenan, is a water-soluble heterogeneous polysaccharide food colloid made from red algae. It is composed of sulfated or nonsulfated D-galactose and 3,6 -Anhydro-L-galactose is connected by α-1,3 glycosidic bonds and β-1,4 bonds, and its molecular formula is (C 12 h 18 o 9 ) n, the two types of carrageenan used more in the food industry are κ-type and ι-type carrageenan. The sulfate-based anion of carrageenan can be associated with Ca2+, K+, etc. through electrostatic interaction to increase the hardness of the gel. In addition, using the synergistic effect of carrageenan and sodium alginate, compounding the two in a certain proportio...

Embodiment 3

[0042]The difference from Example 1 is that in this example, the edible excipient C is added in step 1), that is, the excipient C is fully mixed with the ingredients and the forming agent A, while in step 2), the ingredients, The mixture of molding agent A and excipient C is placed in the extrusion barrel of the nozzle of the 3D printer, wherein the excipient C is a food additive that can produce synergistic effects with the molding agents A and B, and is gelatin, carboxymethyl starch , one or more combinations of xanthan gum, and preferred 0.5% carboxymethyl starch in the present embodiment. Its reaction mechanism is as follows:

[0043] Sodium alginate (forming agent A) + calcium chloride (forming agent B) + carboxymethyl starch (excipient C) → forming entity

[0044] Carboxymethyl starch (CMS) is a modified starch etherified with carboxymethyl. It is odorless, non-toxic, not easy to go moldy, and easily soluble in water. It is widely used as a thickener, suspending agent, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com