Stirring type drug-decocting machine

A decoction machine and stirring technology, which is applied in the field of stirring decoction machines, can solve the problems of low liquid dross content, impure liquid medicine, and easy scaling of decoction tanks, so as to achieve the goal of not easily adhering to medicine scale, reducing the The effect of replacement cost and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

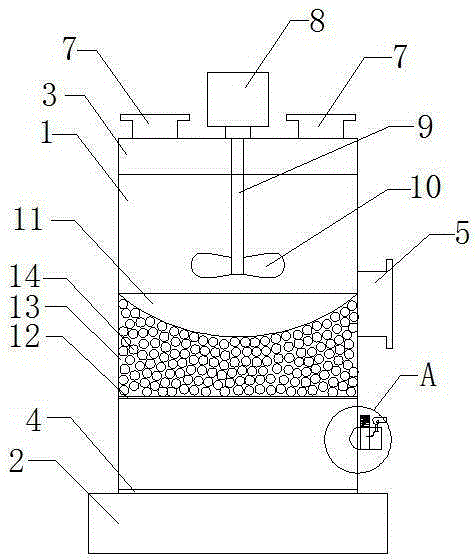

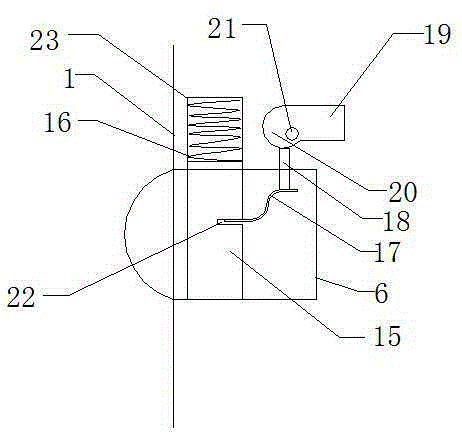

[0032] like figure 1 As shown, a stirring type decoction machine includes a decoction tank 1 and a heating seat 2, the upper part of the decoction tank 1 is provided with a tank cover 3, the lower part is provided with a heating base 4, and one side of the middle part of the decoction tank 1 is There is a drug residue outlet 5, and a drug liquid outlet 6 is provided on one side of the lower part. The inner wall of the side of the decoction tank 1 is evenly coated with a layer of polytetrafluoroethylene layer, and the two sides above the tank cover 3 are respectively equipped with a drug-adding device. The mouth 7 is sealed and connected with the decoction tank 1, and the inner wall of the tank cover 3 is also coated with a polytetrafluoroethylene layer. A power unit 8 is arranged between the medicine feeding ports 7. Transmission connection with a rotating shaft 9, the rotating shaft 9 goes deep into the decoction tank 1, the lower end of the rotating shaft 9 is provided with ...

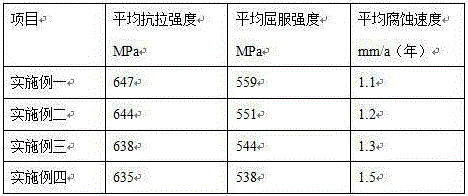

Embodiment 2

[0045] This embodiment is the same as Embodiment 1, except that the special titanium alloy is composed of the following mass percentages: aluminum is 5.0%, tin is 2.0%, nickel is 0.12%, yttrium is 0.045%, and chromium is 0.24%, manganese is 0.53%, vanadium is 5.5%, niobium is 0.56%, zirconium is 0.4-0.94%, and the balance is titanium and its inevitable impurities. The heating base is made by the following steps:

[0046] Step 1, using the existing preparation process for smelting titanium alloys, melting and casting titanium alloys in a vacuum consumable electric arc furnace according to the above-mentioned alloy element ratio, obtaining titanium alloy billets that meet the alloy composition requirements, and casting the obtained titanium alloys Clean the surface of the billet, and then place it in a chamber furnace and heat it to 815°C to remove the scale. The alloy billet is forged by upsetting and drawing deformation to form a forging billet. Among them, the number of fires...

Embodiment 3

[0055] This embodiment is the same as Embodiment 1 and Embodiment 2, except that the special titanium alloy is composed of the following mass percentages: aluminum is 4.8%, tin is 2.3%, nickel is 0.14%, and yttrium is 0.061% , chromium is 0.27%, manganese is 0.7%, vanadium is 5.8%, niobium is 0.89%, zirconium is 0.94%, and the balance is titanium and its inevitable impurities. The heating base is made by the following steps:

[0056] Step 1, using the existing preparation process for smelting titanium alloys, melting and casting the titanium alloys in a vacuum consumable electric arc furnace according to the above-mentioned alloy element ratio, obtaining a titanium alloy billet that meets the requirements of the alloy composition, and casting the obtained titanium alloy Clean the surface of the billet, and then place it in a chamber furnace and heat it to 810°C to remove the scale. The alloy billet is forged by upsetting and drawing deformation to form a forging billet. Among ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com