In-site remediation method for permanently removing heavy metal in farmland soil

An in-situ repair and heavy metal technology, applied in the restoration of polluted soil, etc., can solve the problems of long cycle and slow repair time, and achieve the effect of stable nature, strong adsorption capacity, and not easy to lose.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

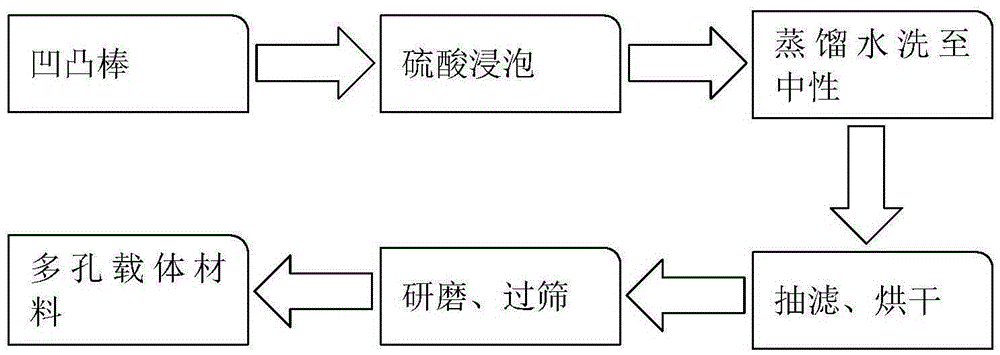

[0029] (1) preparation of porous carrier material, it comprises the following steps:

[0030] (a) place the attapulgite in the container, then add sulfuric acid with a molar concentration of 2-4mol / L in the container, wherein sulfuric acid: the attapulgite ratio is 4ml:1g-6ml:1g;

[0031] (b) placing the attapulgite soaked in sulfuric acid at 18-25°C for 60-120min;

[0032] (c) rinsing the acidified attapulgite with distilled water until the pH is 6-8;

[0033] (d) suction filtering the above mixture, and drying the solid obtained by suction filtration;

[0034] (e) Grinding the dried attapulgite and passing through a 150-mesh sieve, the obtained undersize is a porous carrier material;

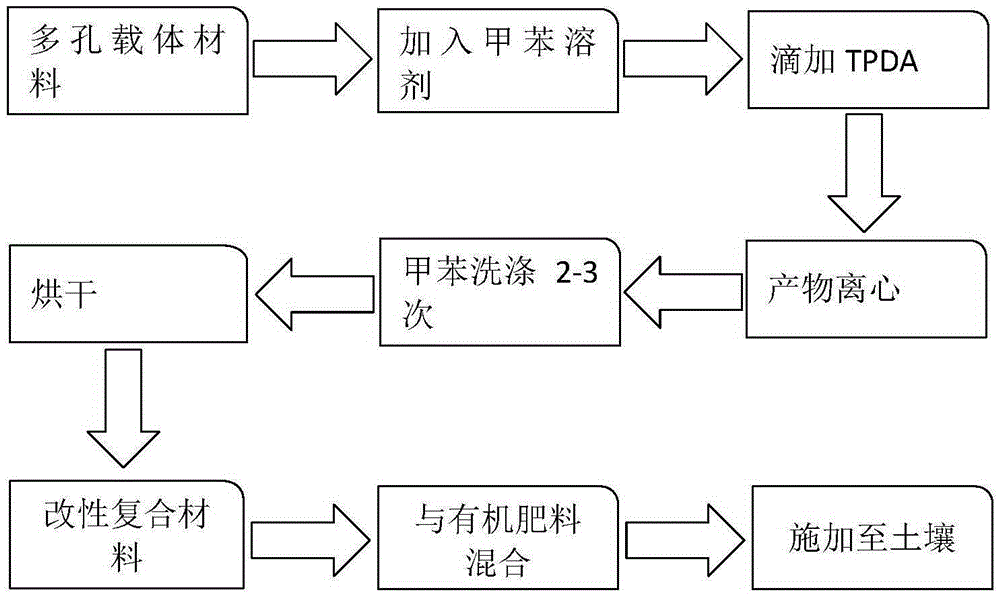

[0035] (2) preparation of modified composite material, it may further comprise the steps:

[0036] (a) taking the porous carrier material prepared in the step (1) and dropping into a toluene solvent to make a porous carrier material toluene solution, wherein toluene: the ratio of the porous...

Embodiment 1

[0045] (1) prepare porous carrier material, concrete steps are:

[0046] (a) the attapulgite is placed in the container, then add 2mol / L sulfuric acid in the container, wherein sulfuric acid: the ratio of the attapulgite is 4ml:1g;

[0047] (b) Place the attapulgite soaked in sulfuric acid at 20°C for 60 minutes;

[0048] (c) rinsing the acidified attapulgite with distilled water until the pH is 6;

[0049] (d) Suction filter the above mixture for about 10 minutes, and dry the solid obtained by suction filtration at 120° C.;

[0050] (e) Grinding the dried attapulgite and passing through a 150-mesh sieve, and the obtained undersize is a porous carrier material.

[0051] (2) Prepare the modified composite material, the specific steps are:

[0052] (a) take by weighing 5.0g porous carrier material and drop in the toluene solvent of 100ml, make porous carrier material toluene solution;

[0053] (b) Add 1.0 g of diethylenetriaminopropyltrimethoxysilane (TPDA) dropwise to the tol...

Embodiment 2

[0061] (1) prepare porous carrier material, concrete steps are:

[0062] (a) the attapulgite is placed in the container, then add 3mol / L sulfuric acid in the container, wherein sulfuric acid: the ratio of the attapulgite is 5ml:1g;

[0063] (b) Place the attapulgite soaked in sulfuric acid at 18°C for 90 minutes;

[0064] (c) rinsing the acidified attapulgite with distilled water until the pH is 8;

[0065] (d) Suction filter the above mixture for about 10 minutes, and dry the solid obtained by suction filtration at 120° C.;

[0066] (e) Grinding the dried attapulgite and passing through a 150-mesh sieve, and the obtained undersize is a porous carrier material.

[0067] (2) Prepare the modified composite material, the specific steps are:

[0068] (a) take by weighing 5.0g porous carrier material and drop in the toluene solvent of 150ml, make porous carrier material toluene solution;

[0069] (b) Add 2.0 g of diethylenetriaminopropyltrimethoxysilane (TPDA) dropwise to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com