Automatically-managed gear machining transmission system

A technology of automatic management and transmission system, which is applied in the field of automatic management of gear processing and transmission system, to achieve the effect of improving economic efficiency, simple structure and safe production management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

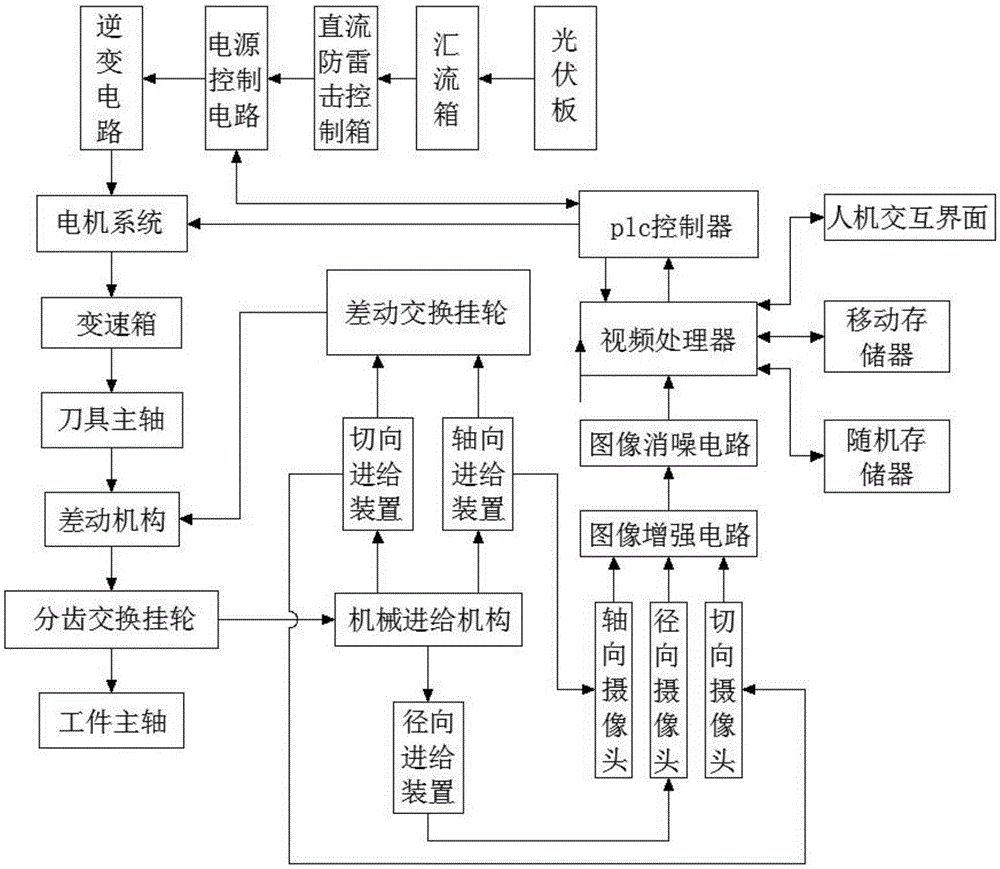

[0028] Automatically managed gear machining transmission systems such as figure 1 As shown, it is specially set up as the following structure: it is equipped with a control system, a motor system, a gearbox, a tool spindle, a differential mechanism, a split gear exchange hanger, a workpiece spindle, a differential exchange hanger, a mechanical feed mechanism and a feed system, the control system is respectively connected to the motor system and the feed system, the electrode system is connected to the gearbox, the output end of the gearbox is connected to the tool spindle, the tool spindle is connected to the differential mechanism, and the differential mechanism is connected to the branch The tooth exchange hanger, the divided tooth exchange hanger is respectively connected to the workpiece spindle and the mechanical feed mechanism, the mechanical feed mechanism is connected to the feed system, the feed system is connected to the differential exchange hanger, and the different...

Embodiment 2

[0035] This embodiment is further optimized on the basis of the above-mentioned embodiments. In order to better realize the present invention, the camera group can be used to process the radial feed device, axial feed device and tangential feed device. Take real-time shooting and provide data support for the formation of new adjustment strategies, such as figure 1 As shown, the following structure is particularly provided: the feed system is provided with a radial feed device, a tangential feed device and an axial feed device, and the mechanical feed mechanism is respectively connected with the radial feed device, The tangential feed device and the axial feed device are connected, and the tangential feed device and the axial feed device are connected with the differential exchange hanging pulley, and the camera group is connected with the radial feed device, the tangential feed device, and the tangential feed device respectively. It is connected to the feed device and the axia...

Embodiment 3

[0037] This embodiment is further optimized on the basis of the above-mentioned embodiments. Further, in order to better realize the present invention, multiple cameras can be used to process the radial feed device, the axial feed device and the tangential feed device respectively. The process is captured in real time and provides data support for the formation of new adjustment strategies, such as figure 1 As shown, the following structure is specially provided: an axial camera, a tangential camera and a radial camera are arranged in the camera group, and the axial camera, the tangential camera and the radial camera are all connected to the image enhancement circuit , the axial camera is connected to the axial feed device, the tangential camera is connected to the tangential feed device, and the radial camera is connected to the radial feed device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com