Strontium barium niobate-based glass ceramic energy storage material and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of the strontium barium niobate based glass-ceramic material with high energy storage density adopts the following steps:

[0039] 1) BaCO with a purity greater than 99.0wt% 3 , SrCO 3 , Nb 2 o 5 , SiO 2 、Al 2 o 3 , B 2 o 3 , is raw material batching, the molar percentage of each above-mentioned component is 20%, 20%, 20%, 35%, 5%, 0%, after mixing by ball milling for 15 hours, drying, and melting at 1600°C for 3 hours;

[0040] 2) Pouring the high-temperature melt obtained in step 1) into a metal mold, annealing for stress relief at 700°C for 5 hours, and then cutting to obtain glass flakes with a thickness of about 1.5 mm;

[0041] 3) The glass flakes prepared in step 2) were kept at 1120° C. for 3 hours for controlled crystallization to obtain glass ceramics.

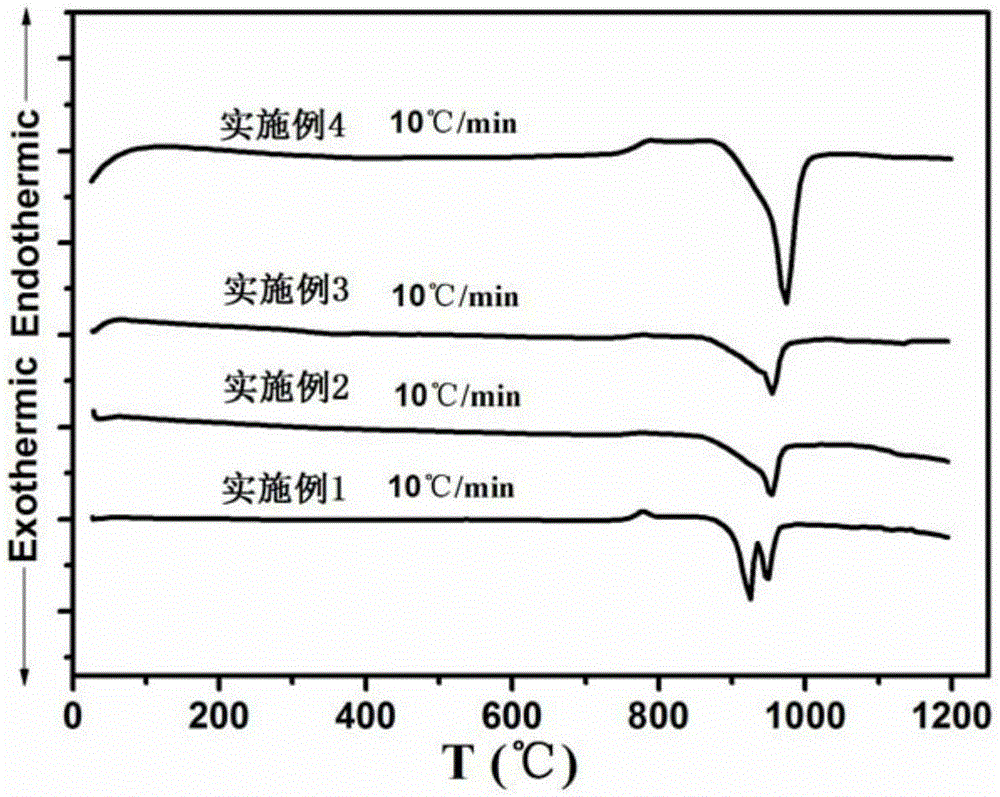

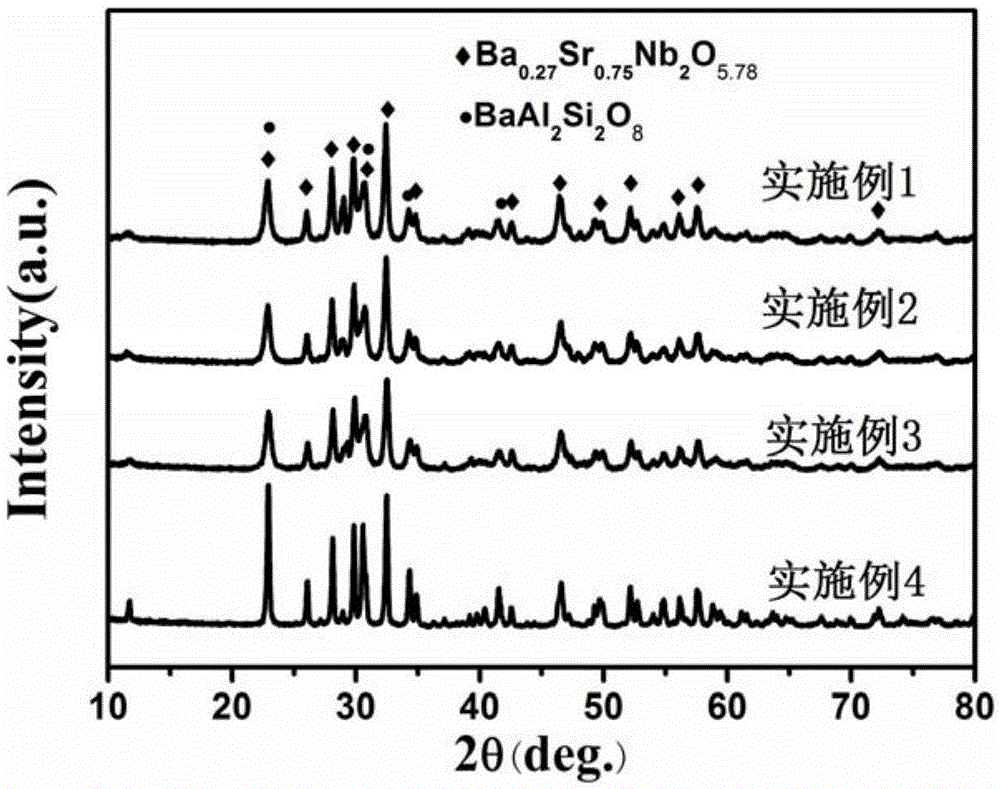

[0042] The DSC of the sample that present embodiment makes is as figure 1 As shown, the DSC curve of this component has two very obvious exothermic peaks; XRD is as follows f...

Embodiment 2

[0044] The preparation method of the strontium barium niobate based glass-ceramic material with high energy storage density adopts the following steps:

[0045] 1) BaCO with a purity greater than 99.0wt% 3 , SrCO 3 , Nb 2 o 5 , SiO 2 、Al 2 o 3 , B 2 o 3 , is raw material batching, and the molar percentage of above-mentioned each component is 20%, 20%, 20%, 33.5%, 5%, 1.5%, after 15 hours of ball mill mixing, drying, melting at 1550 DEG C for 2 hours;

[0046] 2) Pouring the high-temperature melt obtained in step 1) into a copper mold, annealing for stress relief at 650° C. for 5 hours, and then cutting to obtain glass flakes with a thickness of about 1.5 mm;

[0047] 3) The glass flakes prepared in step 2) were kept at 1120° C. for 3 hours for controlled crystallization to obtain glass ceramics.

[0048] The DSC of the sample that present embodiment makes is as figure 1 As shown, the DSC curve of this component has a broad exothermic peak and XRD scanning spectrum co...

Embodiment 3

[0051] The preparation method of the strontium barium niobate based glass-ceramic material with high energy storage density adopts the following steps:

[0052] 1) BaCO with a purity greater than 99.0wt% 3 , SrCO 3 , Nb 2 o 5 , SiO 2 、Al 2 o 3 , B 2 o 3 , is raw material batching, and the molar percentage of above-mentioned each component is 20%, 20%, 20%, 32.5%, 5%, 2.5%, after mixing by ball milling for 15 hours, drying, melting at 1550 ℃ for 2 hours;

[0053] 2) Pouring the high-temperature melt obtained in step 1) into a copper mold, annealing for stress relief at 650° C. for 5 hours, and then cutting to obtain glass flakes with a thickness of about 1.5 mm;

[0054] 3) The glass flakes prepared in step 2) were kept at 1120° C. for 3 hours for controlled crystallization to obtain glass ceramics.

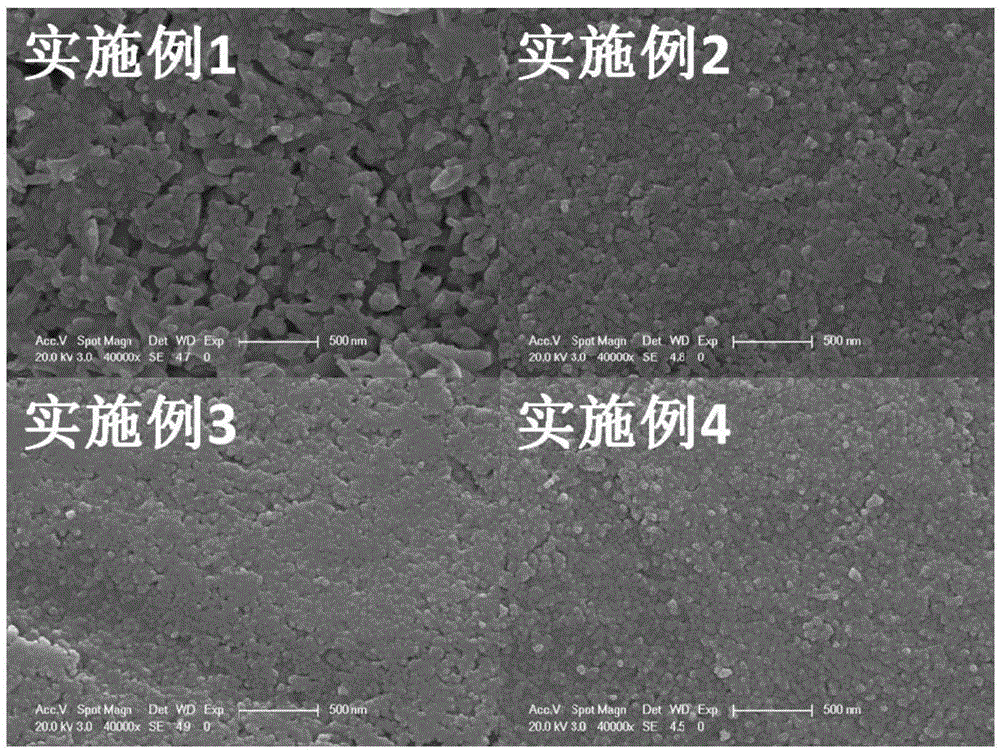

[0055] The DSC of the sample that present embodiment makes is as figure 1 Shown, XRD as figure 2 As shown, SEM as image 3 As shown, the dielectric properties are as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com