Preparation method of ledipasvir key intermediate

A system and technology of amide compounds, applied in the field of preparation of key intermediates of ledipasvir, can solve the problems of unstable compounds, difficult removal of disubstituted impurities, affecting the quality of finished drugs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

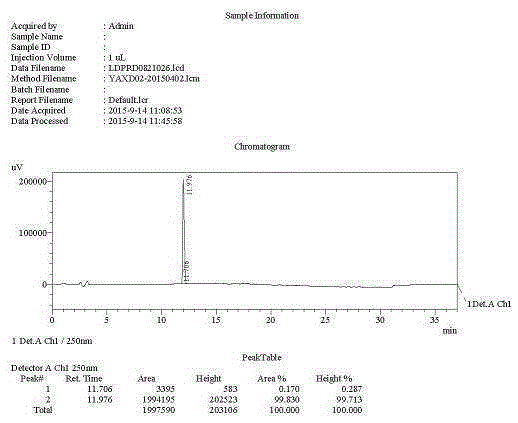

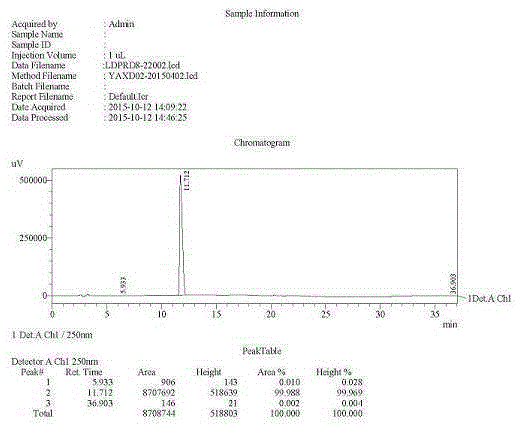

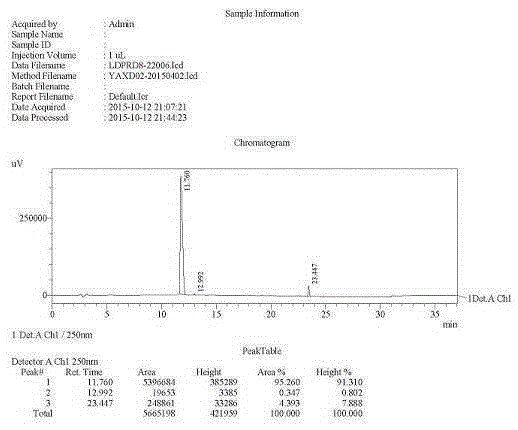

Image

Examples

Embodiment 1

[0026] compound (X) The preparation of (X=Br): in a clean four-neck flask, add IV (10.0g, 0.041mol, 1.0eq) and anhydrous CH 2 Cl 2 (50mL), turn on magnetic stirring (nitrogen protection). Add DMAP (20mg, 0.16mmol) and 4-bromo-2-nitroaniline (9.8g, 0.045mol), stir well after adding, add hydroxybenzotriazole (HOBT) (6.1g, 0.045mol) and 1- Ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride (EDC . HCl) (8.6 g, 0.045 mol). Stir evenly after adding, cool the reaction system to 5°C, then slowly add triethylamine (TEA) (10.4g, 0.10mol), keep the reaction temperature not higher than 10°C during the dropwise addition. After the dropwise addition, the reaction solution was stirred at room temperature for 20 h. After the reaction was completed, the reaction solution was added with H 2 The reaction was quenched with O (50 mL) and the organic phase was separated. CH for aqueous phase 2 Cl 2 (3×40 mL) for extraction; the organic phases were combined, washed with 1M HCl (50 mL...

Embodiment 2

[0028] compound (X) Preparation of (X=Cl): Add anhydrous CH to a 250mL three-necked flask 2 Cl 2 (90mL), methyl chloroformate (7.5g, 0.079mol) and IV (18.0 g, 0.075 mol, 1.0 eq). After the addition, stir until it dissolves. Slowly cool the system down to 0°C, then slowly add diisopropylethylamine (DIPEA, 10.7g, 0.083mol), and keep the system temperature not exceeding 5°C during the dropwise addition. After the dropwise addition, slowly add 4-chloro-2-nitroaniline (14.2g, 0.083mol) in CH 2 Cl 2 (90mL) solution, keep the temperature of the system not exceeding 10°C during the dropwise addition, and it takes 1h. After the dropwise addition, the system was naturally raised to room temperature and stirred for 3 h. Add H2O (100mL) to the reaction system to quench the reaction, let stand to separate the organic phase, and the aqueous phase with CH 2 Cl 2 (3 x 90 mL) extraction. The organic phases were combined and washed with 1M HCl (100 mL) and then with saturated brine, a...

Embodiment 3

[0030] compound (XI) Preparation of (X=Br): DMF (60mL), 5-bromo-2-nitroaniline (8.4g, 0.039mol), IV (8.5g, 0.035mol, 1.0eq) and N-methylmorpholine (7.8g, 0.078mol). After the reaction system was cooled to 0°C with ice-brine, 2-(7-azobenzotriazole)-N,N,N',N'-tetramethyluronium hexafluorophosphate (HATU, 14.6g, 0.038mol ). Subsequently, the reaction was naturally raised to room temperature for 3 h. After the reaction system was concentrated under reduced pressure, the residue was added with H 2 O (50mL) and CH 2 Cl 2 (50mL). Separate the organic phase and use CH for the aqueous phase 2 Cl 2 (3 x 50 mL) extraction. The combined organic phases were washed with 1M HCl (30 mL) and then with saturated brine, and the organic phase was dried over anhydrous sodium sulfate. After filtration, the filtrate was concentrated to dryness under pressure at 40°C, and the residue was purified by silica gel column chromatography (petroleum ether / ethyl acetate, 5 / 1, then 2 / 1) to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com