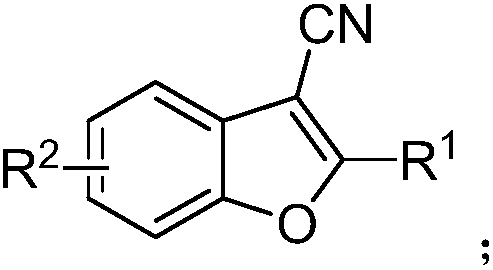

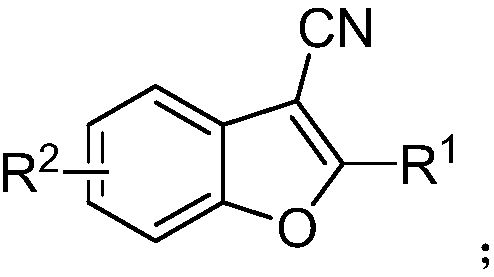

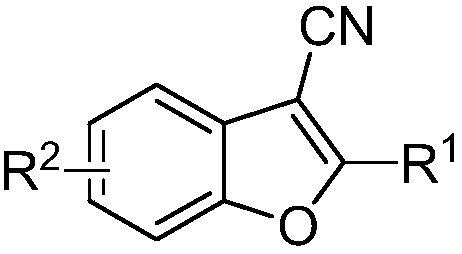

A kind of synthetic method of 2-phenyl-3-cyanobenzofuran compound

A synthesis method and compound technology, which are applied in the field of organic compound cyanation synthesis, can solve the problems of waste of metallic copper, low selectivity and the like, and achieve the effects of reducing processes, readily available reaction raw materials and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

[0021] Example

Embodiment 1

[0023] Add 5-methyl salicylaldehyde (0.5mmol), Cu(OAc) to the reaction flask at room temperature (20-35℃) 2 (0.1mmol), benzylacetonitrile (0.75mmol), sodium methoxide (2mmol) and DMSO (2ml), then stir and heat to 100°C to react until the 5-methylsalicylic aldehyde reaction is complete. After the reaction, the reaction solution was cooled to room temperature, then added to 20ml of water, and extracted with dichloromethane three times, using 10ml of dichloromethane each time, separated by silica gel chromatography, and distilled under reduced pressure. The yield was 74%. The identification result was: White solid, mp 112–113°C. 1 H NMR(400MHz, CDCl 3 ): δ8.16(d,J=7.6Hz,2H), 7.57–7.46(m,4H), 7.43(d,J=8.4Hz,1H), 7.20(d,J=8.4Hz,1H), 2.47 (s,3H). 13 C NMR(100MHz, CDCl 3 ): δ161.6, 151.7, 134.5, 131.0, 129.1, 127.9, 127.7, 127.3, 126.4, 119.62, 114.5, 111.2, 87.7, 21.32. HRMS: Theoretical calculation value C 16 H 11 NO[M + ],233.0841; Test data: 233.0845.

Embodiment 2

[0025] Add 5-methyl salicylaldehyde (0.5mmol), Cu(OAc) to the reaction flask at room temperature (20-35℃) 2 (0.1mmol), p-toluene acetonitrile (0.75mmol), sodium methoxide (2mmol) and DMSO (2ml), then stir and heat to 100°C to react until the 5-methylsalicylic aldehyde reaction is complete. After the reaction, the reaction solution was cooled to room temperature, and then added to 20ml of water, extracted with dichloromethane three times, using 10ml of dichloromethane each time, separated by silica gel chromatographic column, and distilled under reduced pressure. The yield was 56%. The identification result was: White solid, mp 136–137°C. 1 H NMR(400MHz, CDCl 3 ): δ8.06(d,J=8.4Hz,2H),7.48–7.45(m,1H),7.42(d,J=8.8Hz,1H),7.33(d,J=8.0Hz,2H),7.19 (dd,J=8.4,1.2Hz,1H),2.48(s,3H),2.43(s,3H). 13 C NMR(100MHz, CDCl 3 ): δ162.0, 151.6, 141.6, 134.4, 129.8, 127.4, 126.4, 125.2, 119.5, 114.7, 111.1, 87.0, 21.6, 21.3. HRMS: theoretical calculation value C 17 H 13 NO[M + ],247.0997; Test data: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com